Automatic tube butt joint all-position TIG welding technology for coiled tubing

A coiled tube, all-position technology, applied in manufacturing tools, welding equipment, metal processing, etc., can solve the problems of low welding efficiency, high requirements for welders' operation skills, and high labor intensity of welders, so as to improve work efficiency and excellent comprehensive performance , The effect of reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The dimensions and grades of the coiled tubing applicable to this embodiment are pipe diameter 31.75mm (1.25′), wall thickness 3.18mm, QT800 ultra-fine grain steel coiled tubing, yield strength σs≥552Mpa, tensile strength σb≥621MPa , using all-position automatic TIG welding.

[0057] According to the method of the present invention, a V-shaped groove is opened, the angle of groove processing is 75°, the blunt edge is 0.7mm, and there is no gap for pairing.

[0058] Table 1 Process parameters of QT800 coiled tubing

[0059]

[0060] The welded joint performance of embodiment is as follows:

[0061] Stretching test:

[0062] Tensile test results (gauge length 50mm)

[0063] sample

σ b (MPa)

δ(%)

broken state

[0064] Coiled tubing base material

605.5

19

base material

Welded joint sample

627

16.7

fracture in heat affected zone

[0065] Bending test: The bending test of the welded joint ad...

Embodiment 2

[0068] The dimensions and grades of the coiled tubing applicable to this embodiment are pipe 50.8mm (2′), wall thickness 5.18mm, QT900 ultra-fine grain steel coiled tubing, yield strength σs≥630Mpa, tensile strength σb≥715MPa, All-position automatic TIG welding is adopted.

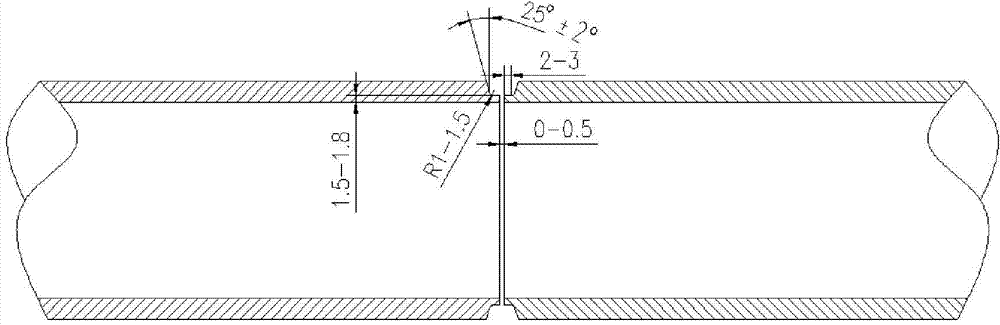

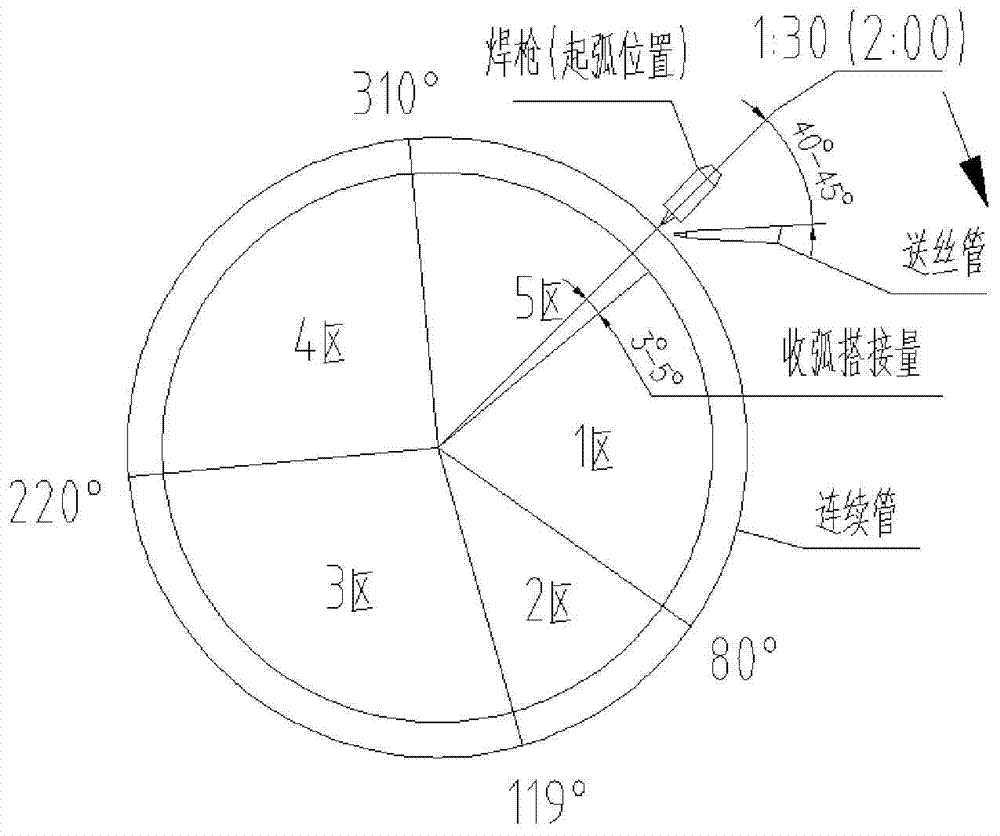

[0069] According to the method of the present invention, a U-shaped bevel is opened, the groove processing slope angle is 25° ± 2°, the blunt edge length is 3mm, the blunt edge thickness is 1.6mm, the radius of the transition arc is 1mm, the pair gap is 0.5mm, and the welding wire model specification : ER70S-6, φ1.0mm, see Table 2 for welding specification parameters.

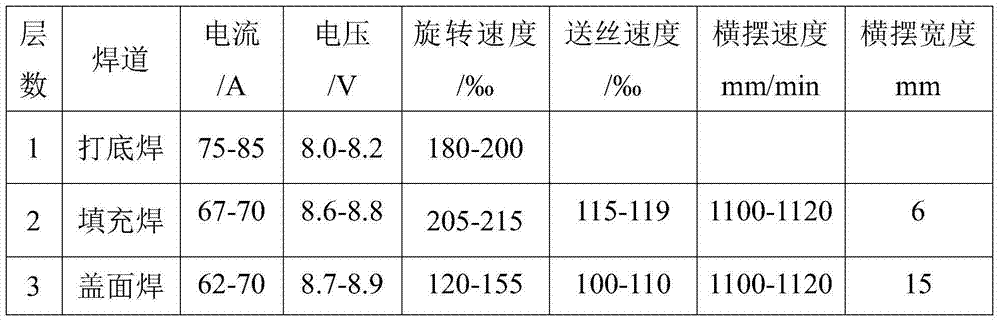

[0070] Table 2 QT900 coiled tubing process parameters

[0071]

[0072] Appearance inspection of QT900 grade coiled pipe welds after welding in this example shows that the surface is well formed and has no welding defects; according to GB / T5097-2005 inspection standards, the welded joints are subjected to non-destructive inspection by p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com