Mine brine pretreatment method

A mine salt and pretreatment technology, applied in the direction of alkali metal chlorides, etc., can solve the problems of large emission of combustion products, insufficient separation degree, pollution of the surrounding environment, etc., and achieve full combustion, stable combustion flame and reduced risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

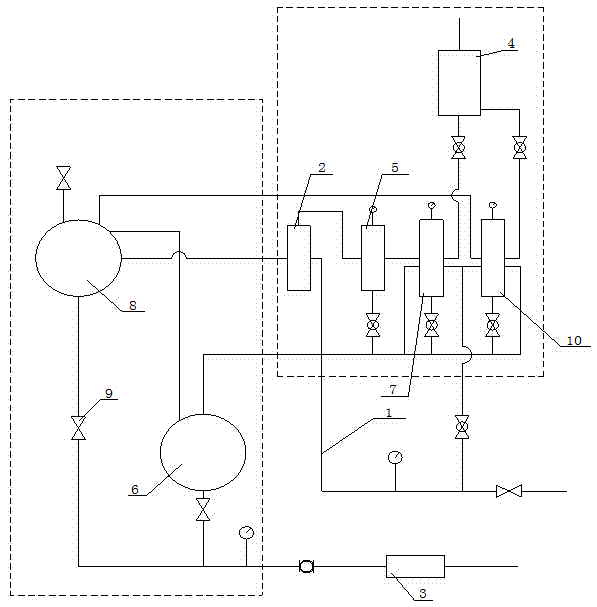

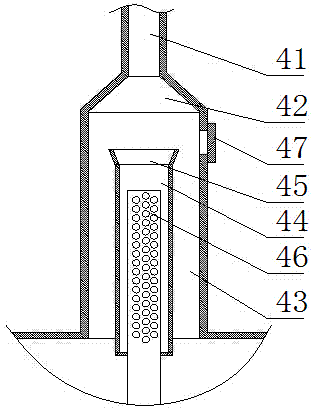

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] When the mine salt and brine pretreatment method of the present invention is specifically implemented: first rely on the brine water inlet main pipe to enter the water, and then rely on a water-gas separator to separate the inlet water into two parts, brine and associated gas, and then transport the brine to the salt production. The workshop carries out salt production, and the associated gas is transported to the exhaust gas combustion device for combustion. The key point is to separate the water contained in the associated gas and return it to the salt production workshop before the associated gas is transported to the exhaust gas combustion device, so as to ensure that the waste gas combustion device Combustion effect and improve brine utilization.

[0031] More specifically, when the present invention is implemented, the mine salt brine pretreatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com