Antiskid and abrasion resistant tire rubber composition

A rubber composition and tire technology, applied in the field of rubber products, can solve the problems of reduced tire service life, high tread hardness, poor wet skid resistance, etc. The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material components: 30 parts of butadiene rubber, 20 parts of natural rubber, 18 parts of EPDM rubber, 10 parts of highly dispersed silica, 20 parts of carbon black N330, 40 parts of carbon black N220, 5 parts of nano zinc oxide, 4 parts of adhesive resin, 1 part of anti-aging agent SP, 1 part of anti-aging agent 4010NA, 2 parts of anti-aging agent BLE, 3 parts of vulcanizing agent, 2 parts of sulfur, 2 parts of accelerator TBZTD-70, 1 part of accelerator CZ, plasticizer DPDP 2 parts, 1.5 parts of silane coupling agent kh570, 1.5 parts of coupling agent Si-69, 5 parts of aromatic oil.

[0034] making process:

[0035] Step 1: Put in butadiene rubber, natural rubber, EPDM rubber, carbon black, anti-aging agent, and tackifying resin and mix for 100-120 seconds at a mixing temperature of 160-180°C and a pressure of 0.56-0.64Mpa;

[0036] The second step: the film is produced and passed through the cooling water tank. Cooling method: fan cooling 8H, natural cooling 1...

Embodiment 2

[0045] Raw material components: 45 parts of butadiene rubber, 30 parts of natural rubber, 20 parts of EPDM rubber, 18 parts of highly dispersed silica, 30 parts of carbon black N330, 40 parts of carbon black N220, 4 parts of nano-zinc oxide, 3 parts of adhesive resin, 1 part of anti-aging agent SP, 2 parts of anti-aging agent 4010NA, 1.5 parts of anti-aging agent BLE, 6 parts of vulcanizing agent, 4 parts of sulfur, 2 parts of accelerator TBZTD-70, 1 part of accelerator CZ, plasticizer DPDP 3 parts, 2 parts of silane coupling agent kh570, 2 parts of coupling agent Si-69, 4 parts of aromatic oil.

[0046] Synthetic method is the same as embodiment 1.

Embodiment 3

[0048] 25 parts of butadiene rubber, 20 parts of natural rubber, 12 parts of EPDM rubber, 10 parts of highly dispersed silica, 20 parts of carbon black N330, 30 parts of carbon black N220, 1 part of nano zinc oxide, 2 parts of tackifying resin , 0.5 parts of anti-aging agent SP, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent BLE, 3 parts of vulcanizing agent, 2 parts of sulfur, 1 part of accelerator TBZTD-70, 1 part of accelerator CZ, 2 parts of plasticizer DPDP, silane 1 part of coupling agent kh570, 1 part of coupling agent Si-69, 2 parts of aromatic oil.

[0049] Synthetic method is the same as embodiment 1.

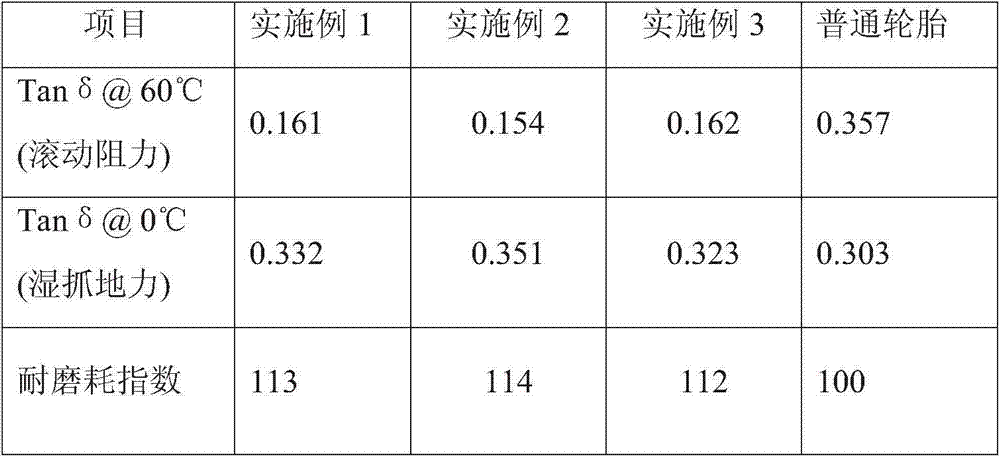

[0050] Table 1 Main technical index of embodiment rubber composition

[0051]

[0052] From Table 1It can be seen that the antiskid tire rubber composition of the present invention is superior to ordinary tires in terms of rolling resistance, wet grip and wear resistance.

[0053] The invention has better wet grip, improves the safety factor of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com