Bitterless pomelo fruit wine and preparation method thereof

A production method and non-bitterness technology, applied in the field of fruit wine brewing, can solve the problems of no effective non-bitterness grapefruit wine production technology, etc., and achieve the effect of simple and easy production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

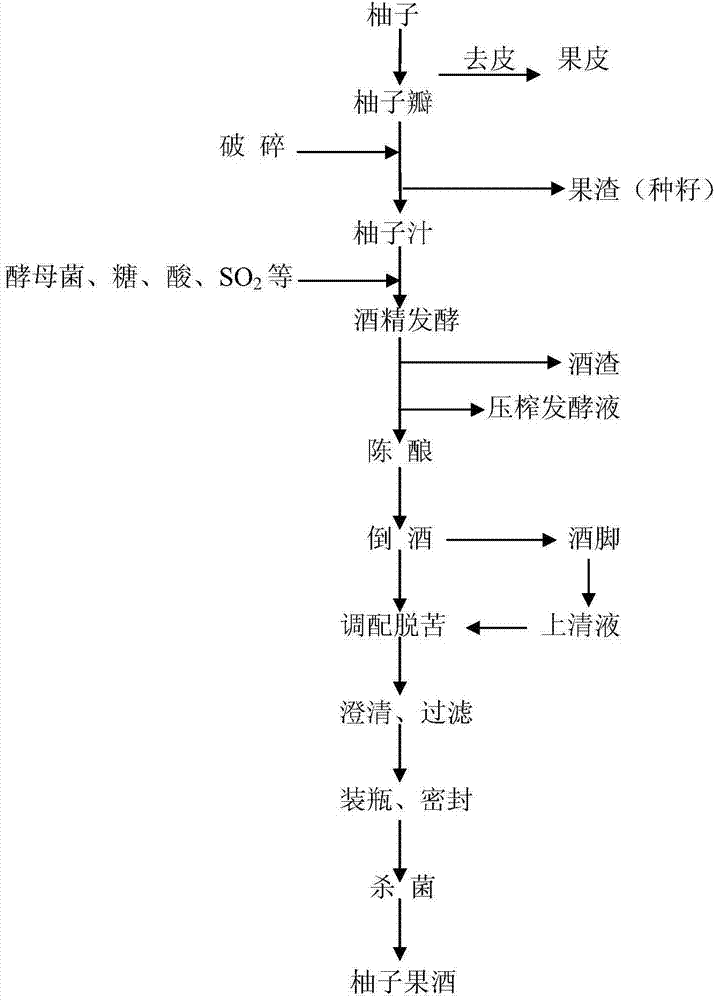

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of production of grapefruit fruit wine without bitterness

[0033] Choose 250kg of seedless pomelo fruit, get about 120kg of pomelo petals after peeling, and use a screw press to crush and get juice. Take about 100kg of grapefruit juice, add SO 2 To a concentration of 60mg / L, add sugar and citric acid to adjust the concentration of soluble solids in the fruit juice to 22g / 100g, pH=3, add well-grown grape fruit wine in a ratio of 3mL / 100mL for alcoholic fermentation, and ferment until the alcohol content is Stop fermentation at 12.0mL / 100mL; during the fermentation process, turn the tank once every 2 days, a total of 3 times, collect all the pomace and press, take the squeezed juice and continue the alcoholic fermentation until the fermentation is completed, and the pressed fermented juice is obtained . Place the fermented liquid fermented after transfer to another container for 2 weeks, transfer the supernatant fermented juice to another container...

Embodiment 2

[0034] Embodiment 2: a kind of production of grapefruit wine without bitterness

[0035] Choose 250kg pomelo fruit, get about 130kg pomelo petals after peeling, adjust the screw press to an appropriate gap, and after confirming that no seeds are squeezed and broken, start the motor to crush and extract juice. Take about 100kg of grapefruit juice; add SO 2 To a concentration of 180mg / L, add starch syrup and malic acid to adjust the concentration of soluble solids in the juice to 24g / 100g and pH=3.5, and add well-grown grape fruit wine at a ratio of 3mL / 100mL for alcoholic fermentation until alcoholic Stop the fermentation when it is 12.0mL / 100mL; during the fermentation process, transfer the tank once every 3 days, and transfer the tank twice in total, collect and squeeze all the pomace, take the squeezed juice and continue the alcoholic fermentation until the fermentation is completed, and press fermentation is obtained. juice. Place the fermented liquid after transfer to an...

Embodiment 3

[0036] Embodiment 3: a kind of production of grapefruit wine without bitterness

[0037]Choose 250 kg of pomelo fruit, peel the pomelo to obtain about 130 kg of pomelo petals, and manually crush them. After placing the slurry for 1 to 8 hours, remove the seeds that sink to the bottom to obtain pomelo juice. Take about 100kg of grapefruit juice; add SO 2 To a concentration of 200mg / L, add rice syrup and citric acid to adjust the concentration of soluble solids in the fruit juice to 25g / 100g and pH=4, and add well-grown grape fruit wine at a ratio of 3mL / 100mL to carry out alcoholic fermentation, and ferment to alcohol Stop the fermentation when it is 12.0mL / 100mL; during the fermentation process, transfer the tank once every 3 days, and transfer the tank 3 times in total, collect and squeeze all the pomace, take the squeezed juice and continue the alcoholic fermentation until the fermentation is completed, and the pressed fermentation is obtained. juice. Transfer the fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com