A kind of anti-ultraviolet nylon bulked filament and its production process

A bulked filament, anti-ultraviolet technology, applied in the field of nylon bulked filament, can solve the problems of high spinning production difficulty, high production cost and high production consumption, and achieves enhanced anti-ultraviolet performance, reduced post-processing procedures, and reduced The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

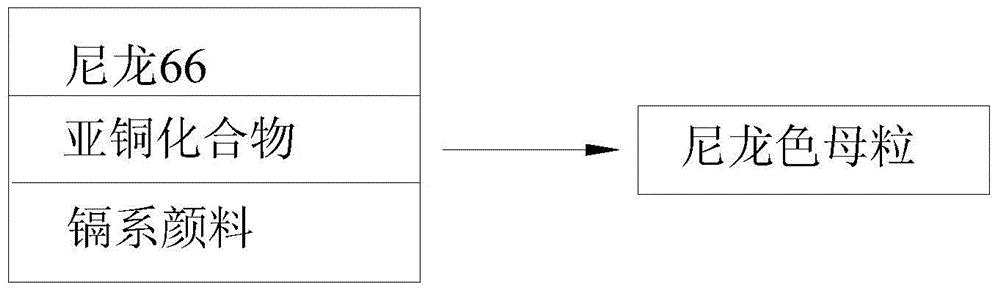

[0047] The raw materials for the preparation of the nylon bulked filament of this embodiment include nylon 66 slices and nylon color masterbatches with a mass ratio of 85:15, and the nylon color masterbatches include base material and cuprous ions, wherein the base material includes nylon color master batches 20% by mass of cadmium pigments and nylon 66 accounting for 80% of the mass of the nylon masterbatch, the content of cuprous ions in the nylon masterbatch is 60ppm, that is, 0.06‰.

[0048] In this embodiment, cuprous ions exist in the form of cuprous compounds, such as CuCl, CuBr, CuI, etc., preferably CuI. The choice of cuprous compounds only needs to satisfy the existence of cuprous ions in the nylon bulked filament.

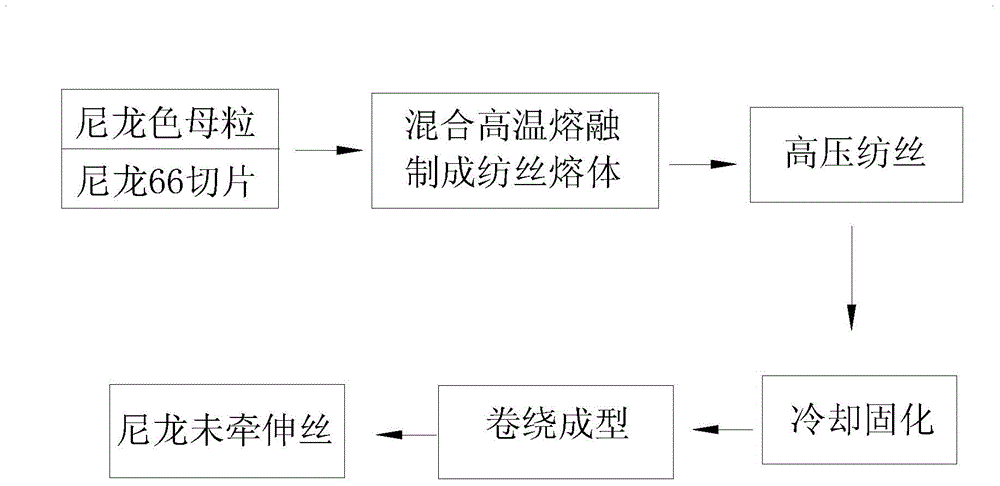

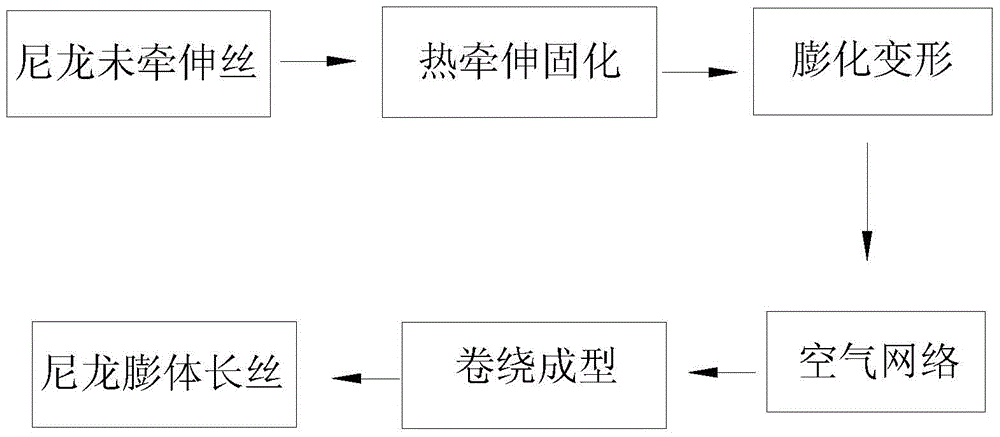

[0049]The preparation method of the present embodiment nylon bulked filament comprises the steps:

[0050] (1) prepare nylon color masterbatch;

[0051] In this step, cuprous ions and cadmium pigments are mixed according to the proportion to obtain an u...

Embodiment 2

[0060] The raw materials for the preparation of the nylon bulked filament of the present embodiment include nylon 66 slices and nylon color masterbatches with a mass ratio of 90:10, and the nylon color masterbatches include a base material and cuprous ions, wherein the base material includes nylon color master batches 35% by mass of cadmium pigments and nylon 66 accounting for 65% of the mass of the nylon masterbatch, the content of cuprous ions in the nylon masterbatch is 100ppm, ie 0.1‰.

[0061] Refer to Example 1 for the production process of the nylon bulked filament in this embodiment.

[0062] After the nylon bulked filament of this embodiment is prepared into a carpet, the UV transmittance of the carpet is 30, which meets the requirements of GB / T18830-2009; The service life has been increased by about 50%.

Embodiment 3

[0064] The raw materials for the preparation of nylon bulked filaments in this embodiment include nylon 66 slices and nylon color masterbatches with a mass ratio of 95:5. Nylon color masterbatches include base material and cuprous ions, wherein the base material includes nylon color master batches 50% by mass of cadmium pigments and nylon 66 accounting for 50% by mass of the nylon masterbatch, the content of cuprous ion in the nylon masterbatch is 150ppm, ie 0.15‰.

[0065] Refer to Example 1 for the production process of the nylon bulked filament in this embodiment.

[0066] After the nylon bulked filament of this embodiment is prepared into a carpet, the UV transmittance of the carpet is 30, which meets the requirements of GB / T18830-2009; The service life has been increased by about 50%.

[0067] Nylon 66 in the above-mentioned embodiment can also adopt other nylons, such as nylon 6, nylon 46, nylon 12, etc. After adding cuprous ions and cadmium pigments to these nylons, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com