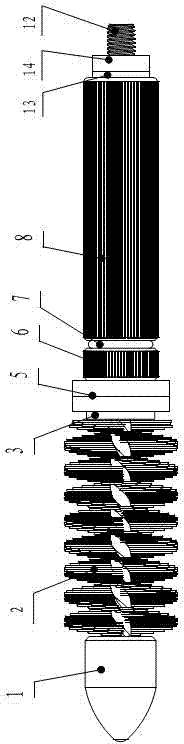

Copper removal brush for gun barrel

A copper brush and gun barrel technology, applied in weapon accessories, offensive equipment, weapon cleaning devices, etc., can solve the problems of deformation of the inner wall of the gun barrel, affecting the shell, corrosion, etc., achieving good sealing, saving cleaning materials, and less consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

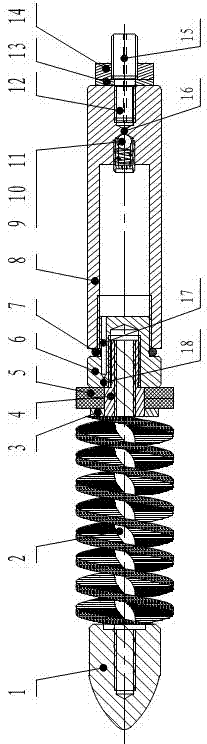

[0009] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0010] The brush handle 8 is a tubular shape with knurling or net pattern on the outer surface. One end is open, that is, the nozzle end. There are internal threads on the inner wall of the nozzle, and the other end has a pipe bottom. The outer end screw hole is threaded in the inner end screw hole to connect the spring seat 9 with external thread, and spring 10 and steel ball 11 are installed in the through hole in the middle of the spring seat to form a one-way valve.

[0011] In the screw hole at the outer end, there is a through hole in the middle and a stepped stud 12 to form an air intake pipe. Also connect washer 13 and rubber pad 14 at the handle outer end of stud 12, do not allow stud 12 to move back and forth and anti-vibration.

[0012] The one-way valve is connected with the air hole 16 in the middle of the intake pipe to become a connected inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com