Imaging three dimensional substrates using a transfer film

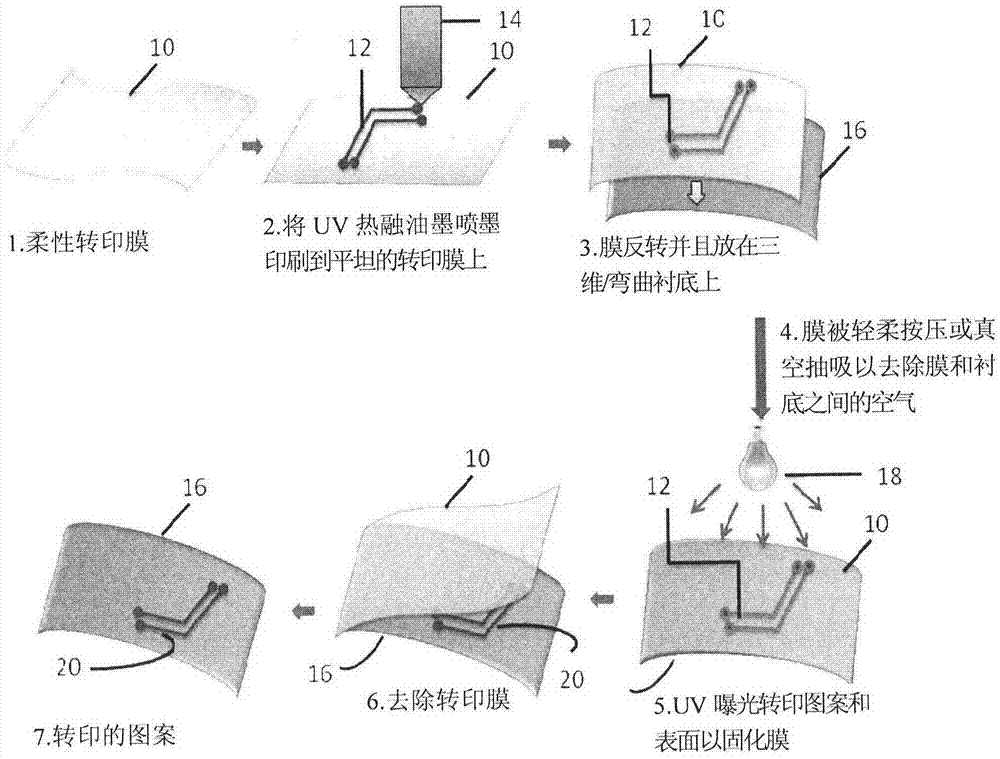

一种三维、衬底的技术,应用在用于光机械设备的光敏材料、对表面涂布液体的装置、图纹面的照相制版工艺等方向,能够解决影响图像分辨率等问题,达到减少工艺步骤、改善分辨率和速度、有效三维衬底成像的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

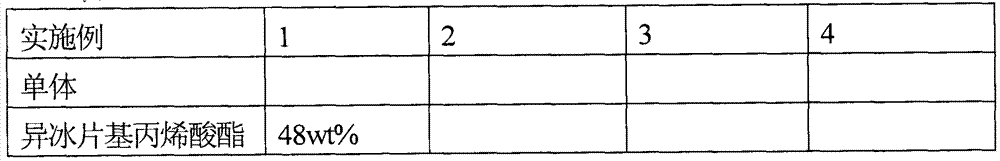

[0050] The following inkjet etch resist compositions were prepared:

[0051] Table 1

[0052]

[0053]

[0054]

[0055] 1 Acrylates from Cytec Industries

[0056] 2 Typical composition and characteristics: abietic acid <3wt%, dehydroabietic acid 6-10wt%, dihydroabietic acid 60-80wt%, tetrahydroabietic acid 5-15wt%, other resin acids and neutrals 10-15wt% %, softening point, Ring&Ball, ℃.=65-69, acid number 158-160

[0057] 3 Hercolyn Floral AX-E from Pinova solutions Inc.

[0058] 4 Hercolyn D-methylhydrorosinate from Pinova solutions Inc.

[0059] All formulations in Table 1 were prepared in the same way. The monomer, wax, plasticizer, and photoinitiator are mixed together at room temperature using conventional laboratory mixing equipment. Formula is 100% solids. The mixture was then heated in a conventional convection oven at a temperature ranging from 85°C to 90°C. The heated resist was then filtered through a conventional laboratory 1.5µ metal filt...

Embodiment 6

[0063] The method described in Example 5 was repeated on multiple copper-clad FR4 / glass epoxy three-dimensional curved panels in thicknesses of 15 μm-30 μm, except that the resist compositions were those prepared in Examples 2-4. The film is selected from polyester, polyethylene terephthalate (PET), polyimide (PI), polyolefin, polycarbonate, polyacrylate and ethylene vinyl acetate. The film does not contain any release agent. Each formulation was ink jetted onto each UV transparent film to form a pattern using the equipment and method described in Example 5. The film with the resist composition is then applied to the curved plate such that the resist is in contact with the curved plate. Each film was gently pressed and rolled with a squeegee to remove air under the film and allow the resist to adhere to the plate. UV light is applied to the film and the film is peeled off the plate. All resists cured and adhered to the board as expected. No resist remained on the membrane ...

Embodiment 7-13

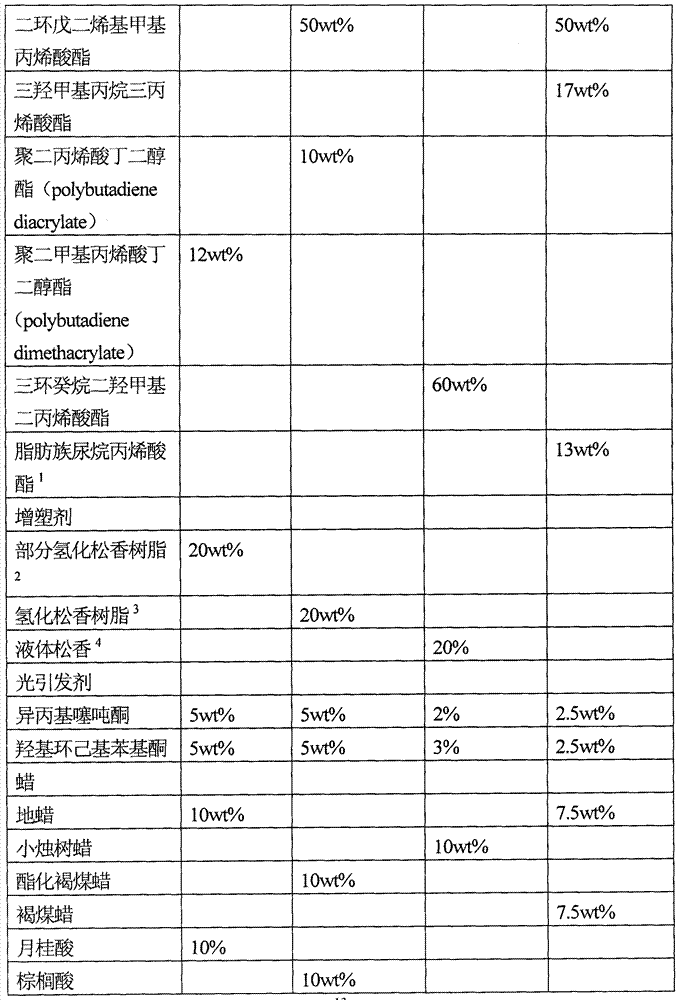

[0066] Table 2

[0067]

[0068]

[0069] The seven resist formulations in Table 2 were all prepared in the same way. Using conventional laboratory mixing equipment, the monomer, acid wax, and free radical initiator mixture are brought together to form a homogeneous mixture. The mixture is heated in a conventional convection oven at 50°C to 90°C to liquefy components that cannot be mixed with other components due to their solid form. After mixing the individual components, cool to room temperature to form a 100% solids composition. The composition is expected to have an acid number greater than 100 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com