Method for improving appearance quality of rear surface of thin sheet

A technology of apparent quality and flakes, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as poor apparent quality and easy metal peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

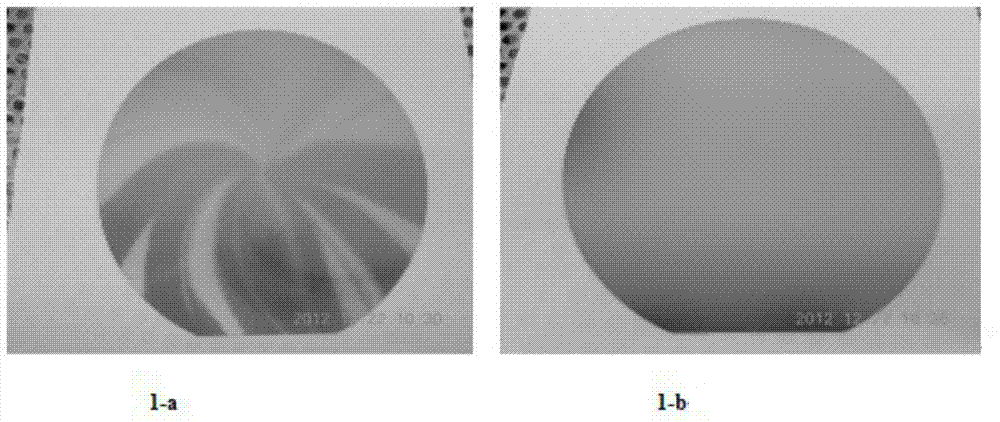

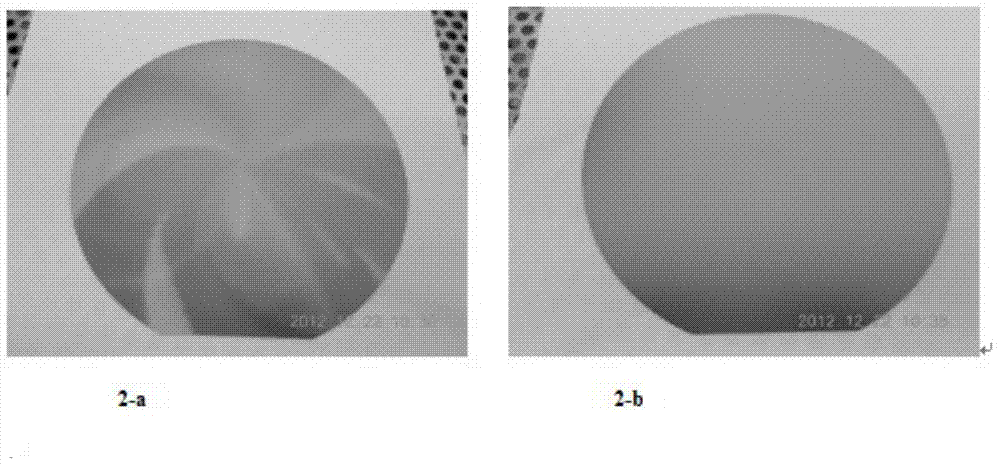

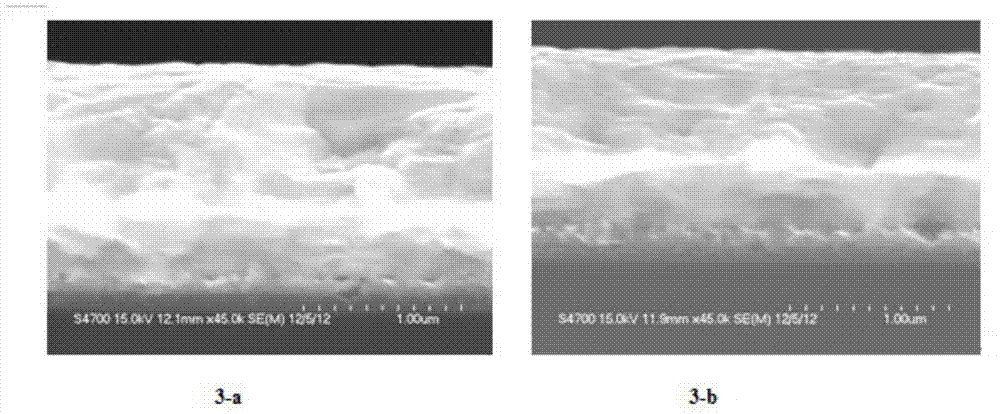

[0028] See figure 1 , 2 、3

[0029] Follow the steps below:

[0030] 1. Apply a film to the front of the wafer to protect the front of the wafer, and the film used is required to have certain acid corrosion resistance;

[0031] 2. Use a 300-mesh grinding wheel and a 600-mesh grinding wheel to thin the wafer processed in step 1 to obtain a thin slice of the required thickness (usually 160um ~ 350um);

[0032] 3. Put the wafer processed in step 2 into the mixed solution according to the volume ratio of hydrofluoric acid (HF): nitric acid (HNO3): glacial acetic acid (CH3COOH) = 1:7:7, and the solution temperature is 25 When ℃~28℃, corrode for 30 seconds;

[0033] 4. Rinse the slices processed in step 3 in deionized water, and after the flushing is completed, perform drying treatment in a dryer with deionized water and nitrogen environment;

[0034] 5. Perform ion implantation on the back side of the slice processed in step 4;

[0035] 6. Carrying out film removal treatment ...

Embodiment 2)

[0042] Follow the steps below:

[0043] 1. Apply a film to the front of the wafer to protect the front of the wafer, and the film used is required to have certain acid corrosion resistance;

[0044] 2. Use a 300-mesh grinding wheel and a 600-mesh grinding wheel to thin the wafer processed in step 1 to obtain a thin slice of the required thickness (usually 160um ~ 350um);

[0045] 3. Put the wafer processed in step 2 into the mixed solution according to the volume ratio of hydrofluoric acid (HF): nitric acid (HNO3): glacial acetic acid (CH3COOH) = 1:7:7, and the solution temperature is 26 When ℃~30℃, corrode for 80 seconds;

[0046] 4. Rinse the slices processed in step 3 in deionized water, and after the flushing is completed, perform drying treatment in a dryer with deionized water and nitrogen environment;

[0047] 5. Perform ion implantation on the back side of the slice processed in step 4;

[0048] 6. Carrying out film removal treatment to the sheet processed in step 5...

Embodiment 3)

[0055] Follow the steps below:

[0056]1. Apply a film to the front of the wafer to protect the front of the wafer, and the film used is required to have certain acid corrosion resistance;

[0057] 2. Use a 300-mesh grinding wheel and a 600-mesh grinding wheel to thin the wafer processed in step 1 to obtain a thin slice of the required thickness (usually 160um ~ 350um);

[0058] 3. Put the wafer processed in step 2 into the mixed solution according to the volume ratio of hydrofluoric acid (HF): nitric acid (HNO3): glacial acetic acid (CH3COOH) = 1:7:7, and the solution temperature is 28 When ℃~30℃, corrode for 1300 seconds;

[0059] 4. Rinse the slices processed in step 3 in deionized water, and after the flushing is completed, perform drying treatment in a dryer with deionized water and nitrogen environment;

[0060] 5. Perform ion implantation on the back side of the slice processed in step 4;

[0061] 6. Carrying out film removal treatment to the sheet processed in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com