A method for fabricating Gan-based LED epitaxial structures with improved crystal quality

An epitaxial structure and crystal quality technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems affecting the crystal quality and performance of epitaxial wafers, high cost, reduce fogging, good electrical yield, and structural quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

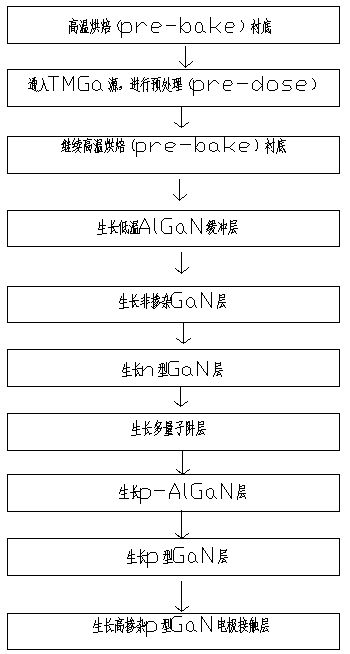

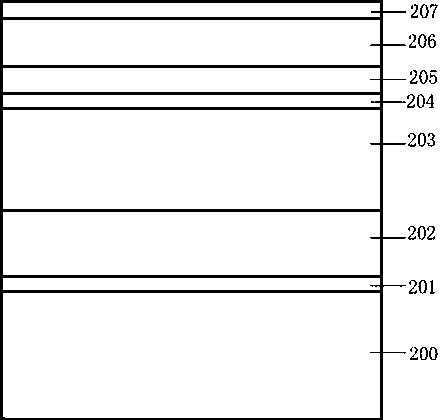

[0017] A method for preparing a GaN-based LED epitaxial structure with improved crystal quality, comprising the following steps:

[0018] Put the sapphire substrate with (0001) crystal orientation into the MOCVD reaction chamber, and then 2 Raise the temperature to 1180°C in the environment for high-temperature baking (pre-bake) the substrate, stabilize it for 400s, turn on the TMGa source, keep the TMGa flow rate at 25sccm for 30s, continue high-temperature baking (pre-dose) the substrate for 170s, and cool down to 550 ℃, grow a 30nm thick GaN buffer layer at 600mbar, raise the temperature to 1150℃ to grow a 2.5um thick non-doped GaN layer, and grow a 3um thick n-type GaN layer at 1150℃, in N 2 The multi-quantum well layer was grown for 12 cycles in the environment, the GaN barrier layer: the thickness is 13nm, the growth temperature is 850°C; the InGaN well layer: the thickness is 2nm, the growth temperature is 760°C, and the temperature is raised to 1000°C to grow 60nm thic...

Embodiment 2

[0020] A method for preparing a GaN-based LED epitaxial structure with improved crystal quality, comprising the following steps:

[0021] Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 The temperature was raised to 1200°C in the environment, and the substrate was pre-dose at high temperature, stabilized for 400s, and the TMGa source was connected, and the flow rate of TMGa was kept at 30sccm for 50s, and the substrate was pre-dose continued at high temperature for 150s, and the temperature was lowered to 550°C, grow a 10nm thick GaN buffer layer at 600mbar, raise the temperature to 1150°C to grow a 2.5um thick non-doped GaN layer, grow a 3um thick n-type GaN layer at 1150°C, and grow a 3um thick n-type GaN layer at 1150°C. 2 The multi-quantum well layer was grown for 12 cycles in the environment, the GaN barrier layer: the thickness is 13nm, the growth temperature is 850°C; the InGaN well layer: the thickness is 2nm, the growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com