Plasma non-stick pan and manufacturing method thereof

A non-stick pan and plasma technology, applied in the field of kitchen utensils, can solve the problems of easy cracking, short service life, strong brittleness, etc., and achieve the effects of remarkable thermal stability and non-stickiness, improved service life and long wear resistance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

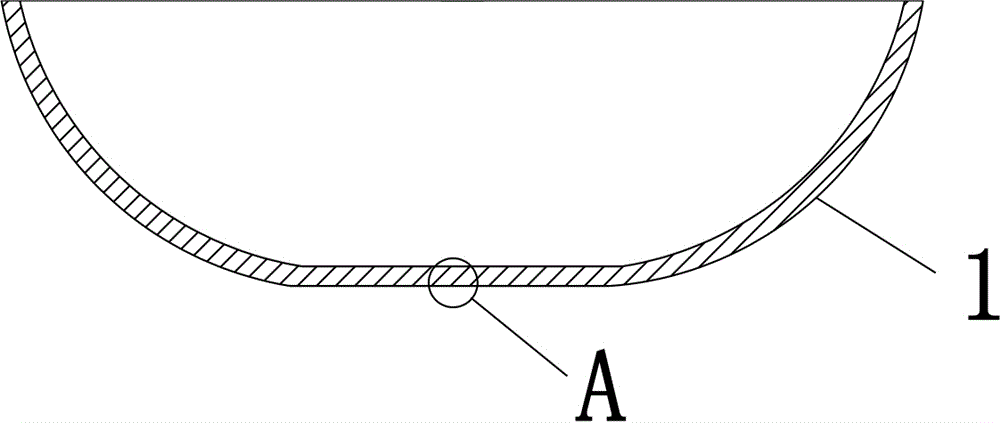

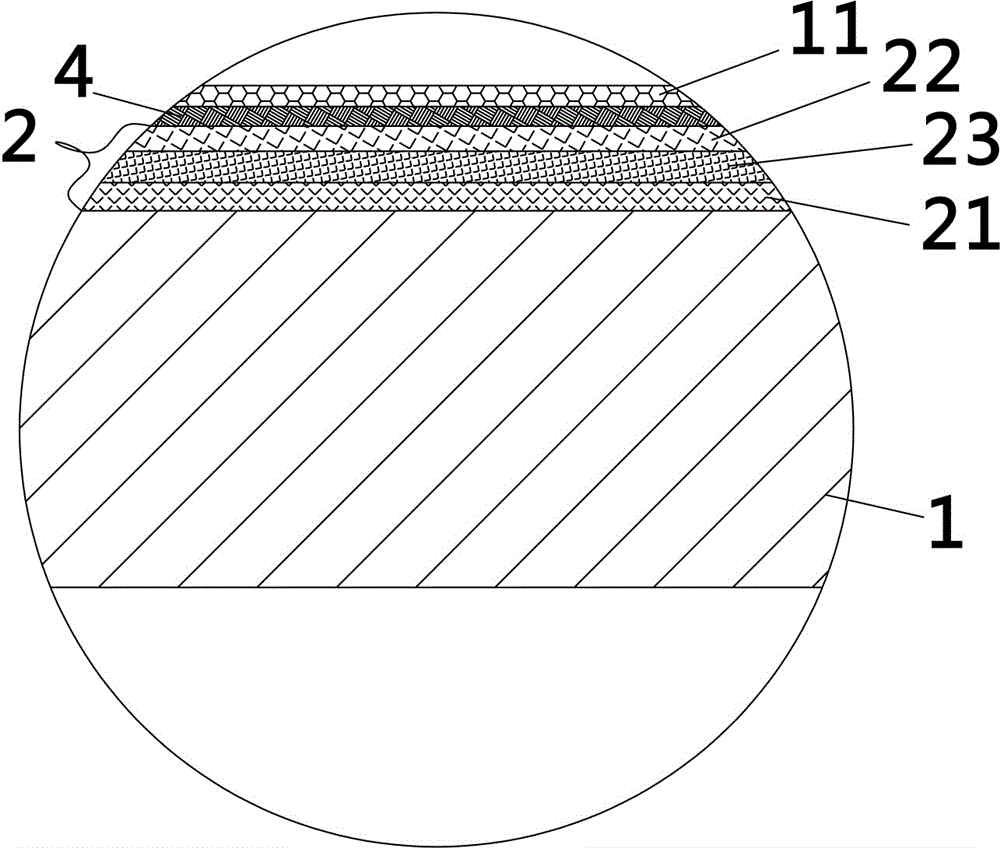

[0027] Such as figure 1 , 2 as shown, figure 2The thicknesses indicated by the coatings in are not actual proportions, and are enlarged for ease of understanding; a plasma non-stick pan, comprising a pan body 1, the pan body has an inner surface made of an aluminum substrate, on the inner surface Coated with a non-stick coating 11, a plasma layer 2 is provided between the non-stick coating and the inner surface of the pot, and the plasma layer includes a MCrALY layer 21 coated on the inner surface of the pot body 1 and a MCrALY layer coated on the inner surface of the pot body 1. A mixture layer 22 outside the layer 21, the mixture layer is composed of MCrALY particles and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com