Space paint spraying air purification system

An air purification system and air supply system technology, which is applied in the field of air purification, can solve the problems of air dust, particles and other impurities, health hazards of internal staff, and influence on the quality of painting, etc. Simple, the effect of suppressing the spread of paint mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

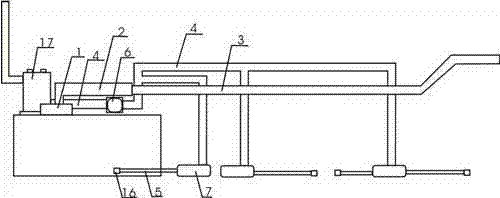

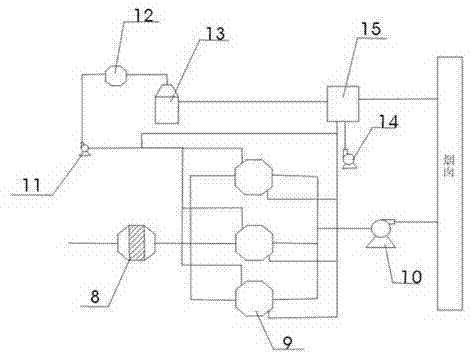

[0012] When in use, the air supply fan box 1 runs, and the air supply fan box 1 transmits the wind through the air supply pipe 2 to the composite fiber bag air duct 3, and the composite fiber bag air duct 3 emits the wind; the mobile paint mist collection unit on the lower side 16 to collect the paint mist, and transmit the paint mist to the exhaust interface box 7 through the telescopic exhaust duct, and the exhaust interface box 7 transmits the paint mist to the activated carbon adsorption catalytic combustion device 17 through the exhaust duct 4 and the exhaust fan box 6 to process. The activated carbon adsorption catalytic combustion device 17 filters the received paint mist through the high-efficiency fiber filter 8, and the treated paint mist is sent to the adsorption bed 9 for processing, and part of the paint mist processed by the adsorption bed 9 is sent to the desorption fan 11 and the other Part of it is sent to the main fan 10 and the main fan 10 is discharged ...

Embodiment 2

[0014] Take the whole machine spray paint as an example

[0015] First of all, before the painting work starts, after the original production preparation procedures are ready, start to operate this set of purification system. During operation, in order to save time, three people (at most) can be arranged to operate without any tools, and the total operation time is about 30 minutes. One of them is responsible for connecting the segmented air supply ducts with unions on the ladder frame. The other two people operate the exhaust system on the ground, and the two are on both sides of the aircraft, dragging the mobile paint mist collection unit and the telescopic mobile exhaust duct connected to it to the designated location. After the air supply pipe is connected and the exhaust air collection unit is arranged, only one person needs to activate the paint spray purification button in front of the system control panel to operate the entire paint mist purification system.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com