Kernel I-grade 2209 double-phase stainless steel welding wire and manufacturing method

A duplex stainless steel, manufacturing method technology, applied in the direction of manufacturing tools, welding media, welding equipment, etc., can solve the problems of unfavorable development of nuclear power industry, long procurement cycle, difficult quality control, etc., and achieve excellent pitting resistance and good workmanship Performance and mechanical properties, the effect of small splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

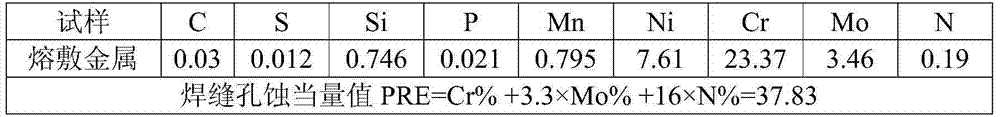

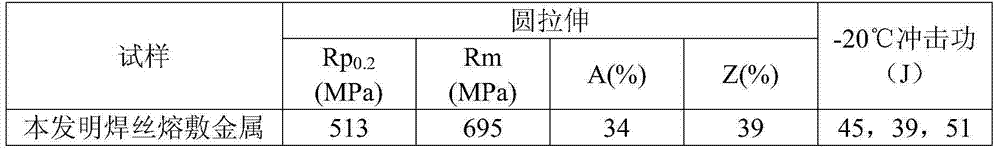

Examples

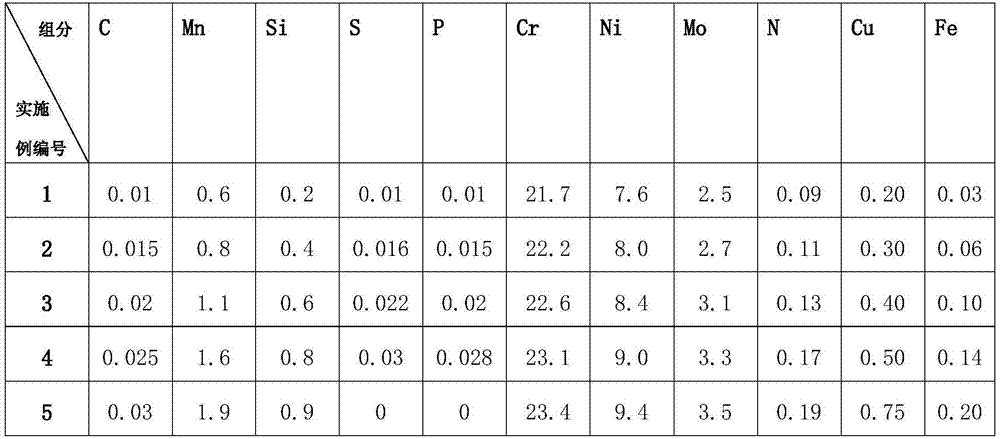

Embodiment 1~5

[0040] For above embodiment 1~5, a kind of manufacturing method of nuclear grade I 2209 duplex stainless steel welding wire, its steps are:

[0041] (1) Mix the pure iron contained in the formula with elements that are difficult to be oxidized such as Ni, Cr, and Mo, and then melt it in a vacuum induction furnace. During the melting period, the vacuum degree is controlled below 7.83Pa, and then add the formula to the furnace content of Si, N, Cu, stir fully after complete melting;

[0042] (2) When the melting temperature reaches 1580°C, when the molten steel is calm, cut off the power and pump it to a vacuum for 20-25 minutes, then turn on the power to raise the temperature. After the conjunctiva is melted, add C in the formula for refining, and the refining temperature is kept at 1580°C-1600°C , the refining time is 25-30 minutes;

[0043] (3) Cool down 10 minutes before tapping, fill with Ar320-420Pa after fully and evenly stirring, add the Mn content in the formula, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com