Compound polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of compound polycarboxylate water reducing agent and its preparation, can solve the problems of reduced comprehensive performance of concrete, poor mud resistance, easy insertion, etc., and achieves no toxic side effects and stable properties. , the effect of increasing the physical size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]The hydroxyl-terminated polyether macromonomer of Example 1 is obtained by esterifying the terminal hydroxyl of the polyether macromonomer with the carboxyl group of a macromolecular carboxylic acid under the catalysis of a catalyst; the polyether The molar ratio of the macromonomer to the macromolecular carboxylic acid is 1:0.2-1; the reaction temperature of the esterification reaction is 80°C-130°C. Wherein the polyether macromonomer adopts isopentenyl polyoxyethylene ether (TPEG) or isobutenyl polyoxyethylene ether (HPEG). Specifically, the catalyst can use p-toluenesulfonic acid or sulfamic acid, and its consumption depends on the consumption of the polyether macromonomer; specifically, the consumption of the catalyst can be 2% of the mass of the polyether macromonomer ~6%.

[0047] Specifically, the catalyst uses p-toluenesulfonic acid or sulfamic acid.

[0048] The structural formula of the polyether macromonomer that is esterified at the hydroxyl end is as follo...

Embodiment 2

[0061] Since the esterification reaction is a reversible reaction, if the H generated during the esterification reaction 2 Accumulation of O in the reaction vessel will accelerate its reverse reaction. Therefore, in order to improve the efficiency of the esterification reaction, on the basis of the raw material of the polyether macromonomer that is esterified with terminal hydroxyl groups used in Example 1, in the raw material of the polyether macromonomers that are esterified with terminal hydroxyl groups in this embodiment, add A water-carrying agent is used, and the amount of the water-carrying agent is 10% to 20% of the mass of the polyether macromonomer. Specifically, cyclohexane can be used.

[0062] Further, in order to prevent the double bond polymerization of the reaction raw material polyether macromonomer in the reaction process, in the esterification reaction, a polymerization inhibitor is also added; the consumption of the polyether macromonomer is 0.05% to 0.5%...

Embodiment 3

[0067] The polycarboxylate superplasticizer mother liquor is obtained by mixing the hydroxyl-terminated polyether macromonomer described in Example 1 with water, an initiator, a chain transfer agent and acrylic acid for heating and reaction, and then adding it to the alkaline solution And the pH value is obtained after reaching 6-7.

[0068] The mixing ratio of the hydroxyl-terminated polyether macromonomer and water, initiator, chain transfer agent and acrylic acid used in the polycarboxylate superplasticizer mother liquor of the present invention adopts the existing mixing ratio, and the existing initiator , chain transfer agent. However, as an example, this Example 3 gives a specific ratio, but it cannot limit the polycarboxylate superplasticizer mother liquor of the present invention.

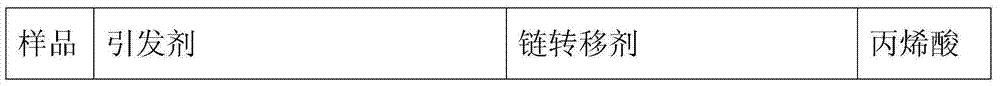

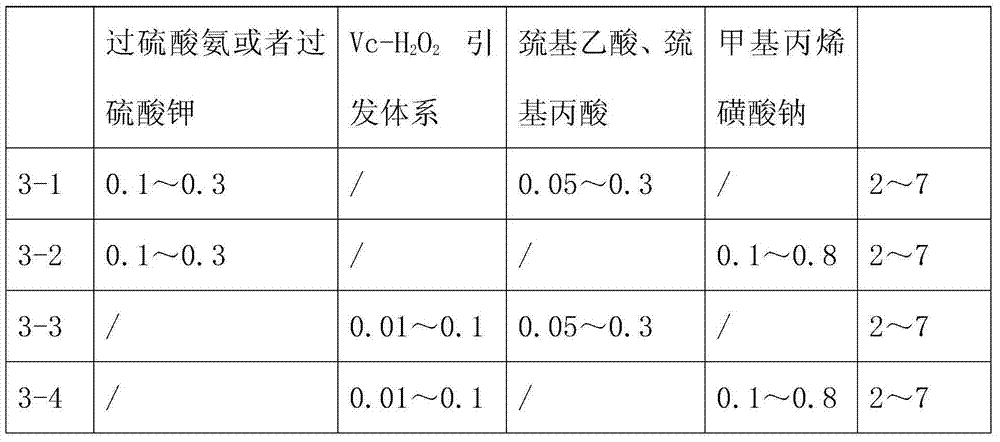

[0069] The molar ratio of water, initiator, chain transfer agent and acrylic acid used in Example 3 to the molar ratio of the hydroxyl-terminated polyether macromonomer is shown in Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com