Fireproof insulation board and manufacturing method thereof

A fireproof insulation board and a manufacturing method technology, applied in the field of building insulation materials, can solve the problems of poor insulation effect, long construction period, inadequate protective measures, etc., to improve waterproof performance and physical and mechanical properties, improve waterproof performance and Effect of tensile strength, improved fit and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

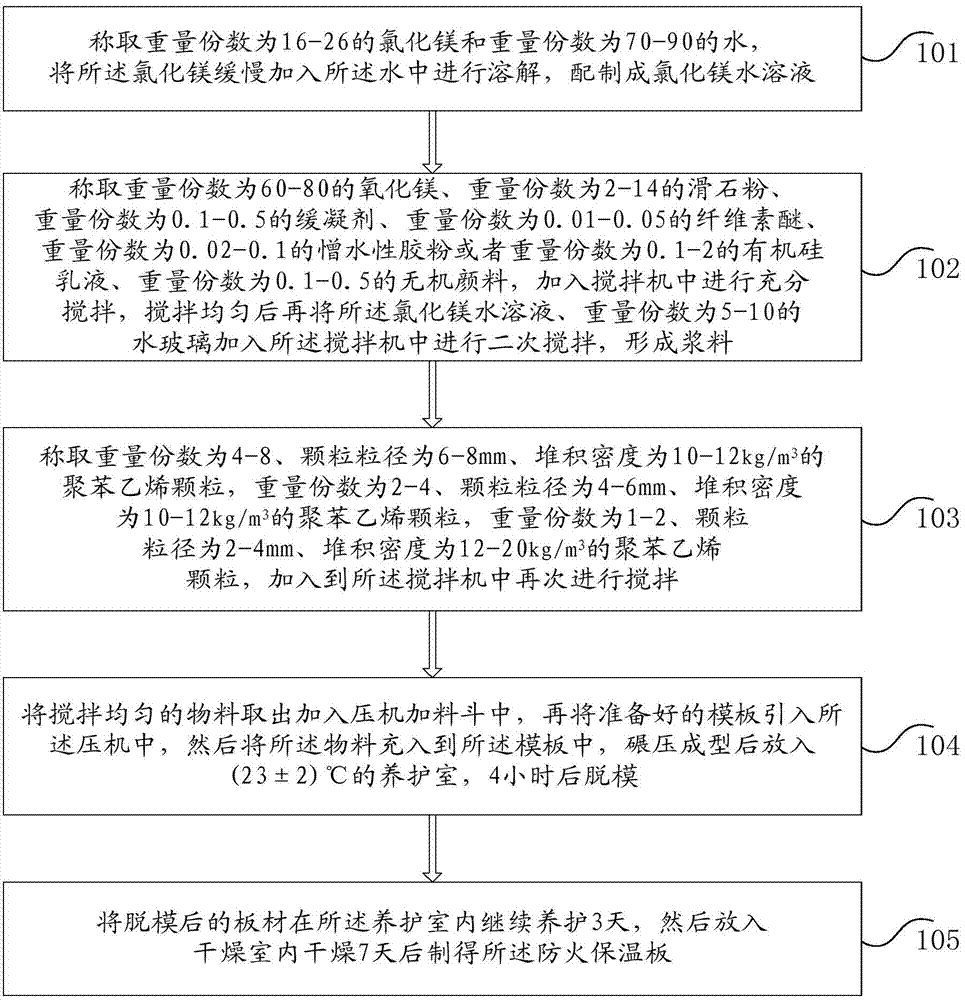

Method used

Image

Examples

Embodiment 1

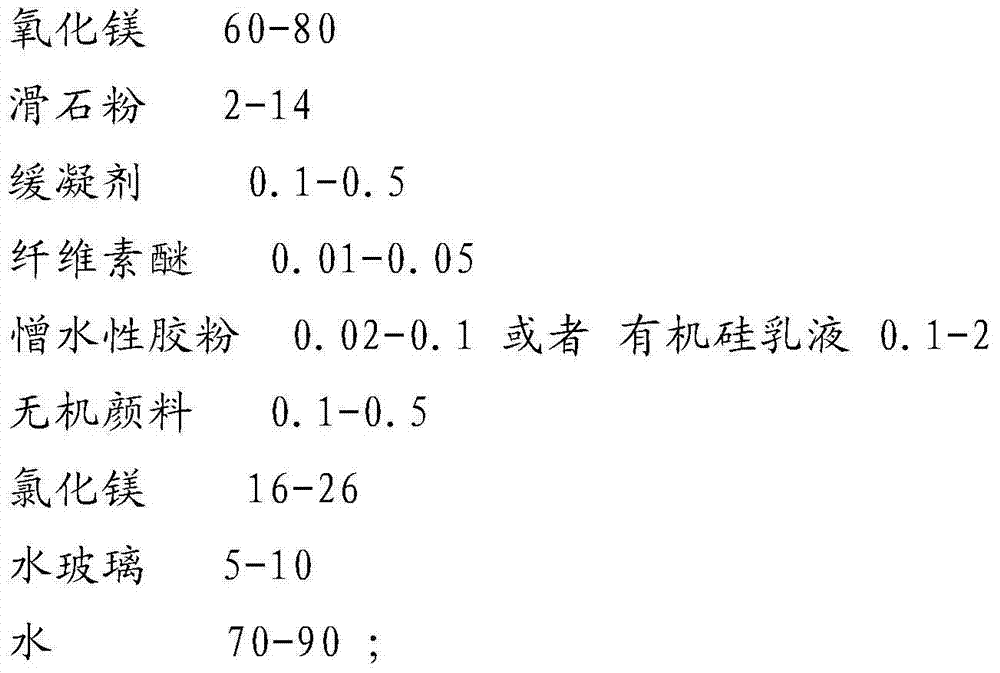

[0040] The present invention provides a kind of fire insulation board, comprises A component and B component, wherein:

[0041] The component that A component comprises and the parts by weight of each component are:

[0042]

[0043] The component that B component comprises and the parts by weight of each component are:

[0044] The particle size is 6-8mm, and the bulk density is 10-12kg / m 3 Polystyrene pellets 4

[0045] The particle size is 4-6mm, and the bulk density is 10-12kg / m 3 Polystyrene pellets 2

[0046] The particle size is 2-4mm, and the bulk density is 12-20kg / m 3 Polystyrene pellets1.

[0047]According to the above-mentioned embodiments of the present invention, the fire-proof and heat-preservation boards can prolong the production and opening time in the production process of the boards; improve the waterproof performance and tensile strength of the boards; endow the fire-proof heat-preservation boards with more excellent fireproof performance, and comp...

Embodiment 2

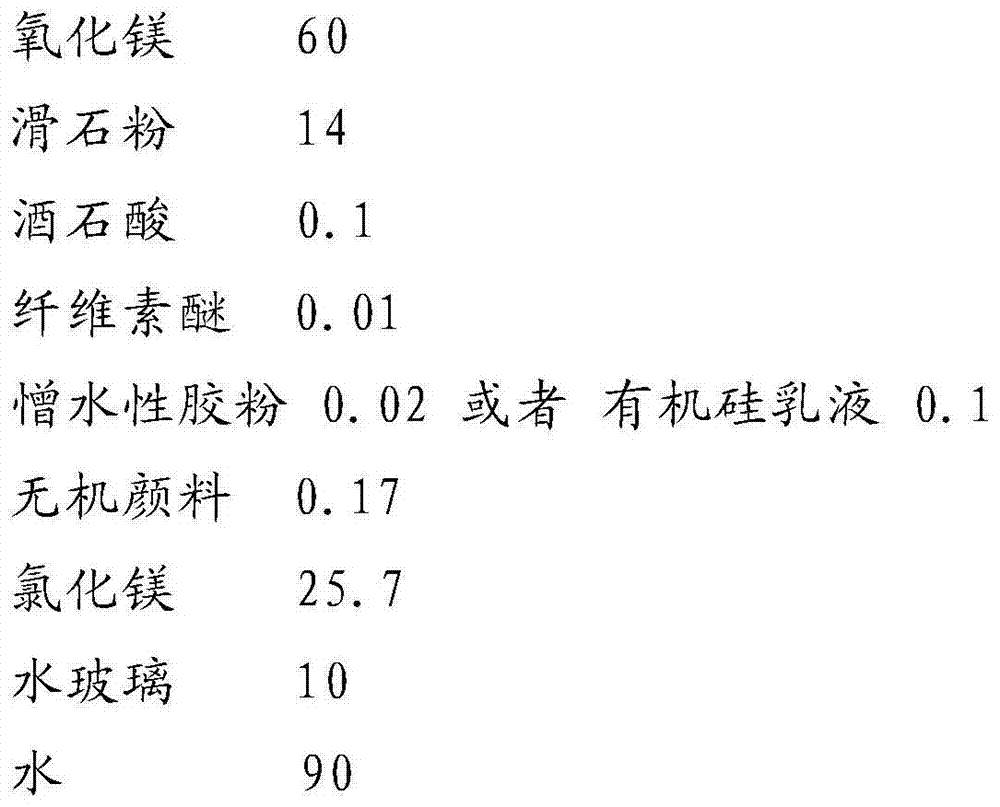

[0056] The present invention provides a kind of fire insulation board, comprises A component and B component, wherein:

[0057] The component that A component comprises and the parts by weight of each component are:

[0058]

[0059]

[0060] The component that B component comprises and the parts by weight of each component are:

[0061] The particle size is 6-8mm, and the bulk density is 10-12kg / m 3 Polystyrene pellets6

[0062] The particle size is 4-6mm, and the bulk density is 10-12kg / m 3 Polystyrene Granules 3

[0063] The particle size is 2-4mm, and the bulk density is 12-20kg / m 3 Polystyrene pellets 1.5.

[0064] The fireproof and thermal insulation board provided by the above-mentioned embodiments of the present invention also overcomes the defects in the prior art and solves the technical problems to be solved by the present invention.

Embodiment 3

[0066] The present invention provides a kind of fire insulation board, comprises A component and B component, wherein:

[0067] The component that A component comprises and the parts by weight of each component are:

[0068]

[0069] The component that B component comprises and the parts by weight of each component are:

[0070] The particle size is 6-8mm, and the bulk density is 10-12kg / m 3 Polystyrene pellets of 8

[0071] The particle size is 4-6mm, and the bulk density is 10-12kg / m 3 Polystyrene pellets of 4

[0072] The particle size is 2-4mm, and the bulk density is 12-20kg / m 3 Polystyrene pellets 2.

[0073] The fireproof and thermal insulation board provided in this embodiment can also overcome the defects in the prior art and solve the technical problems to be solved in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com