Branch ditch castable for blast furnace casting house containing homogeneous material and preparation method thereof

The technology of homogeneous material and castable is applied in the field of blast furnace smelting high temperature refractory material, which can solve the problems of quality fluctuation of sintered bauxite, and achieve the effects of good construction performance, good corrosion resistance and broad market prospect.

Active Publication Date: 2017-04-12

TONGDA REFRACTORY TECH CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019]

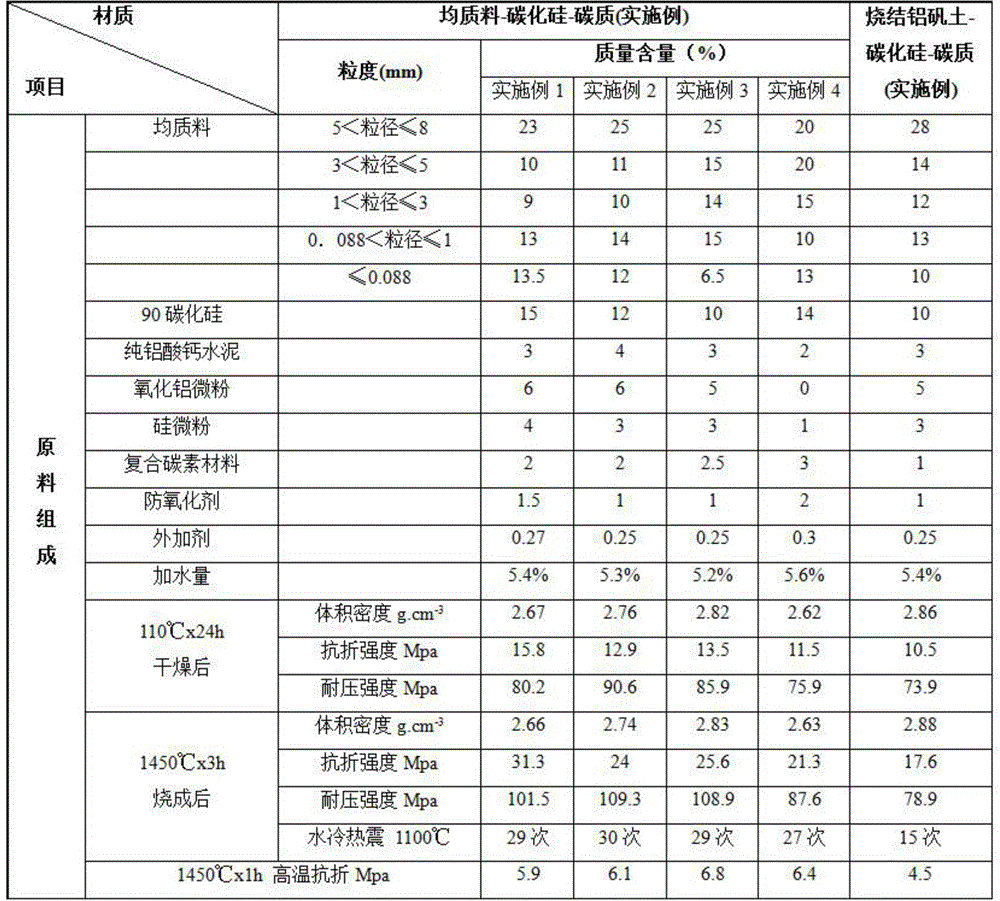

[0020] Note: The admixtures stated are added in addition to the rest of the components.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a homogenized material-containing blast furnace tapping yard branch channel castable and a preparation method thereof, and belongs to the technical field of blast furnace smelting high temperature refractory materials. The castable comprises the following raw materials, 20-25wt% of a homogenized material with the particle size of greater than 5mm and not greater than 8mm, 10-20wt% of a homogenized material with the particle size of greater than 3mm and not greater than 5mm, 5-15wt% of a homogenized material with the particle size of greater than 1mm and not greater than 3mm, 10-15wt% of a homogenized material with the particle size of greater than 0.088mm and not greater than 1mm, 5-15wt% of homogenized material fine powder with the particle size of not greater than 0.088mm, 10-15wt% of 90 silicon carbide, 2-5wt% of pure calcium aluminate cement, 0-10wt% of alumina micro-powder, 1-5wt% of silicon micro-powder, 1-3wt% of a composite carbon material and 1-3wt% of an antioxidant, and also comprises 0.2-0.3wt% of an additive. The castable has the advantages of good construction performance, good erosion resistance, prolonged service life and cost reduction.

Description

technical field [0001] The invention belongs to the technical field of blast furnace smelting high-temperature refractory materials, and in particular relates to a branch ditch castable for a blast furnace casting house containing homogeneous materials and a preparation method thereof. In particular, it relates to a homogeneous material-silicon carbide-carbon refractory castable technology and a preparation method thereof for a blast furnace iron channel. Background technique [0002] At present, the refractory materials of the blast furnace ironmaking system are mainly alumina, aluminum silicon carbide (carbon) refractory materials, mainly high alumina bauxite and alumina powder as the main raw materials, which are prepared by sintering or melting. White corundum, fused brown corundum, and sintered tabular corundum are the main products, and the demand for alumina and aluminum silicon carbide (carbon) refractory materials accounts for a large proportion of the total refract...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/66C04B35/622

Inventor 赵春燕王安杰占华生陈茂峰安建成陈庆帅辛健张海波李燕京

Owner TONGDA REFRACTORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com