Optical engine timing mechanism, optical engine timing method and optical engine

A technology of optical engine and timing mechanism, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of incorrect determination of timing results, danger of piston top valve, time-consuming and labor-intensive problems, and achieve improved timing accuracy and connection High-intensity, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

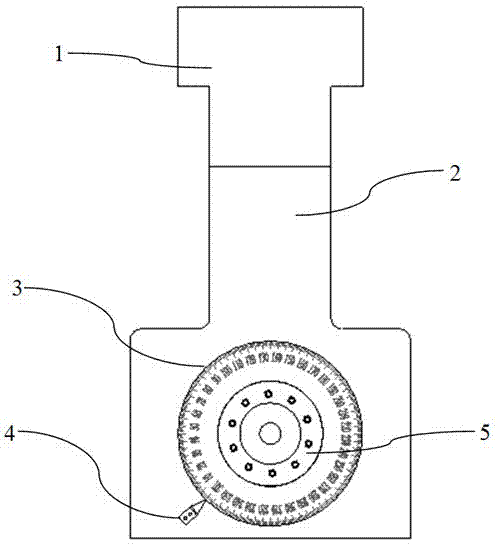

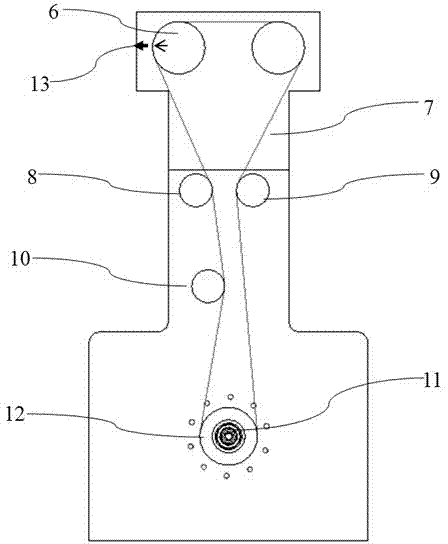

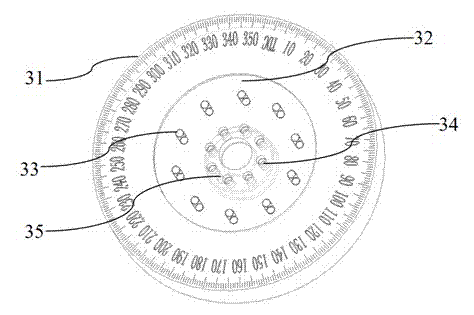

[0028] The timing mechanism of the optical engine of the present invention is as attached figure 1 to attach image 3 As shown, it includes flywheel assembly 3, crankshaft positioning pointer 4, timing gear 6, timing belt 7, first fixed idler 8, second fixed idler 9 and timing belt tensioner 10. The optical engine of the timing mechanism includes a cylinder head assembly 1, a cylinder block assembly 2, a crankshaft 11, a coupling flange 5, a crankshaft pulley 12 and a dynamometer. The specific schematic structure of the optical engine is shown in the attached figure 1 And attached figure 2 As shown, the cylinder head assembly 1 includes a cylinder head body, a transparent cylinder l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com