Rubber laminate

A rubber layer and integration technology, applied in the direction of rubber layered products, layered products, hoses, etc., can solve the problems of insufficient heat resistance, poor vulcanization adhesion of fluororubber, increased defect rate, etc., and achieve scorch stability. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

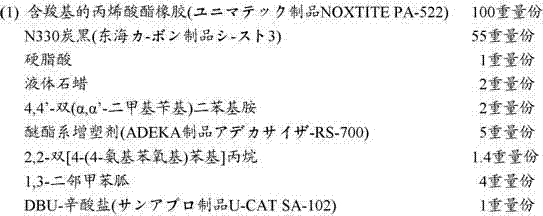

[0046]

[0047] The above-mentioned components were kneaded using an 8-inch roll, and then an unvulcanized sheet with a thickness of 3 to 4 mm was produced.

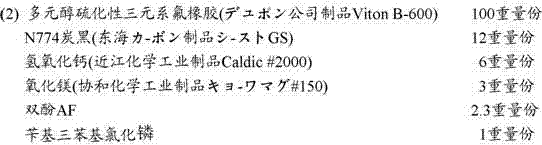

[0048]

[0049] The above-mentioned components were kneaded using an 8-inch roll, and then an unvulcanized sheet with a thickness of 3 to 4 mm was produced.

[0050] (3) Overlay the unvulcanized sheet formed of the above-mentioned carboxyl group-containing acrylate rubber composition and the unvulcanized sheet formed of the polyol vulcanizable fluororubber composition under the conditions of temperature 160°C, surface pressure 10MPa, and time 30 minutes. Under pressure molding, open vulcanization (secondary vulcanization) was performed at 175°C for 4 hours to form an acrylic rubber / fluororubber laminate.

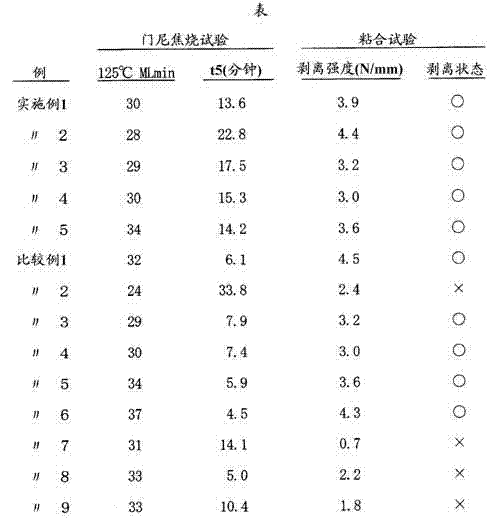

[0051] For the sample (15 x 100 x 5 mm) obtained by shearing the obtained rubber laminate, a peeling test was performed according to JIS K6256 (peeling speed: 50 mm / min), and the measurement of the peeling force ...

Embodiment 2

[0054] In Example 1, the amount of 1,3-di-o-tolylguanidine was changed to 6 parts by weight and used.

Embodiment 3

[0056] In Example 1, an equivalent amount (1 part by weight) of DBU-toluenesulfonate (U-CAT SA506, manufactured by Sunapro) was used instead of DBU-octanoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com