Modular aerating/oxygenating device

A modular, aeration technology, applied in water aeration, biological treatment devices, aerobic process, etc., can solve problems such as installation, maintenance, replacement difficulties, large amount of gas supply pipeline construction, poor aeration performance, etc. Achieve the effects of easy online maintenance or replacement, low cost, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

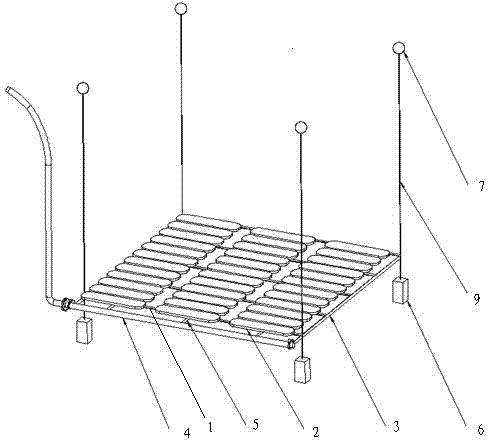

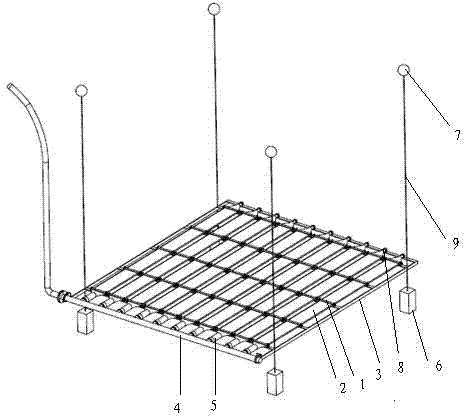

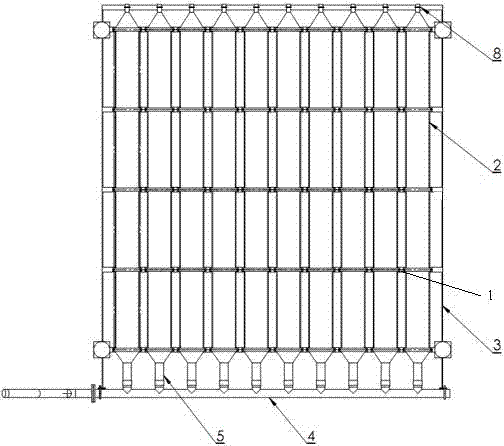

[0019] Embodiment 1, a modular aeration and oxygenation device, including a plate aerator 2, a square frame 3, an air distribution pipe 4, an air distribution adapter 5, a counterweight 6, a buoy 7, a rigging 9, and the square frame 3 is parallel A number of aerators 2 are arranged, one end of each aerator 2 is connected to an air distribution adapter 5, the air distribution adapter 5 is connected to the air distribution pipe 4, and the other end of each aerator is blocked and fixed on the square frame; The weight 6 is fixed below the four corners of the square frame 3 through the rigging 9, and the other end of the rigging 9 is equipped with a buoy 7; the square frame 3 is provided with connecting pieces 1 at intervals, and the connecting pieces 1 connect the exposures arranged in parallel. The gas device 2 and the square frame 3 are fixedly connected as one.

Embodiment 2

[0020] Embodiment 2, referring to Embodiment 1, the aerator 2 is a hose-type aerator, and one end of each aerator is fixed on the square frame 3 by the end fixing member 8, and the connecting parts are arranged at intervals in the square frame 3 1. The coupling piece 1 clamps the hose type aerator, and the two ends of the coupling piece 1 are fixed on the square frame 3 .

[0021] Note: According to the actual situation of the treatment, the above-mentioned modular aeration and oxygenation device is composed of the air distribution pipe and the air distribution adapter. The air distribution component is made of polymer materials or metal. to 160mm; the square frame is made of metal, the square frame is 1m to 10m long and 1m to 10m wide.

[0022] In addition, the failure of the aeration equipment in the aeration process of the sewage treatment plant in operation, such as outage for maintenance, not only the cleaning of the tank to replace the aeration equipment itself has a lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com