Preparation method of Pt-Ni alloy nano tube array electrode and application for enzyme-free glucose sensor

A technology of alloy nano-array electrodes, which is applied in the preparation of Pt-Ni alloy nanotube array electrodes and the application field of enzyme-free glucose sensors, can solve the problems of high cost of experimental materials, complicated operation, high equipment requirements, etc., to improve sensitivity, Obvious catalytic effect, good linear range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

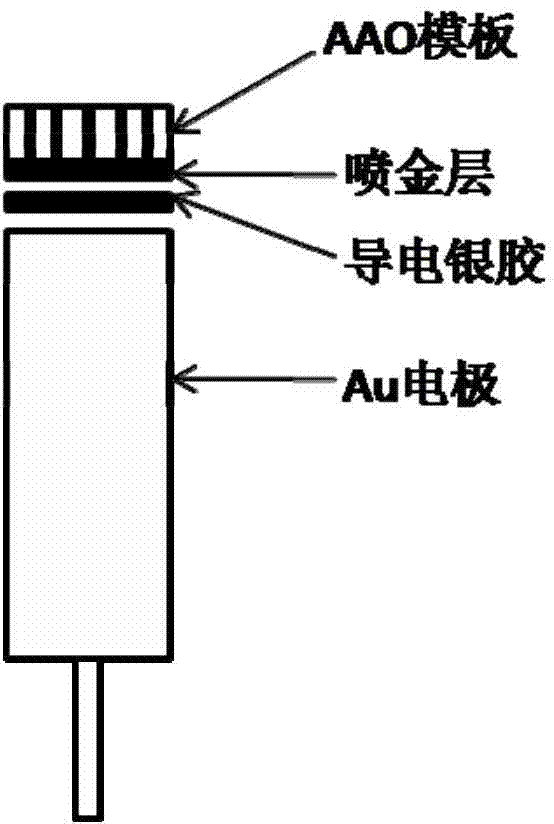

[0042] Before using the Au electrode (diameter 4mm), use 1.0 μm, 0.3 μm and 0.05 μm alumina powder to polish the surface of the electrode in a figure-eight shape on the suede, and then use deionized water and ethanol to repeatedly ultrasonically clean it for 5 times until the electrode surface is The mirror surface is smooth, and then in 0.1M phosphate buffer solution with pH=6.86, the scanning voltage window is -0.3-0.8V, and the cyclic voltammetry scans for 10 cycles until the scanning curve is stable. The AAO template with a pore size of 200nm is sprayed with gold on one side before use as an electrodeposited conductive layer, and a drop of conductive silver glue is dripped on the surface of the Au electrode. After the conductive silver glue is evenly spread, quickly fix the gold sprayed side of the AAO template on the On the surface of the Au electrode, use insulating silicone rubber to fix the edge of the AAO template, leave the AAO template with the size of the Au electro...

Embodiment 2

[0047] Before using the Au electrode (4mm in diameter), polish the surface of the electrode with polished flannelette, and then use deionized water and ethanol to repeatedly ultrasonically clean it 3 times until the surface of the electrode is mirror-smooth. 15 laps until the scanning curve is stable. Spray gold on one side of the AAO template before use, and drop a drop of conductive silver glue on the surface of the Au electrode. After spreading the conductive silver glue evenly, quickly fix the gold-sprayed side of the AAO template on the surface of the Au electrode, and use insulating silicone rubber to fix it. On the edge of the AAO template, leave an AAO template the size of the Au electrode area, and let it dry for 24 hours.

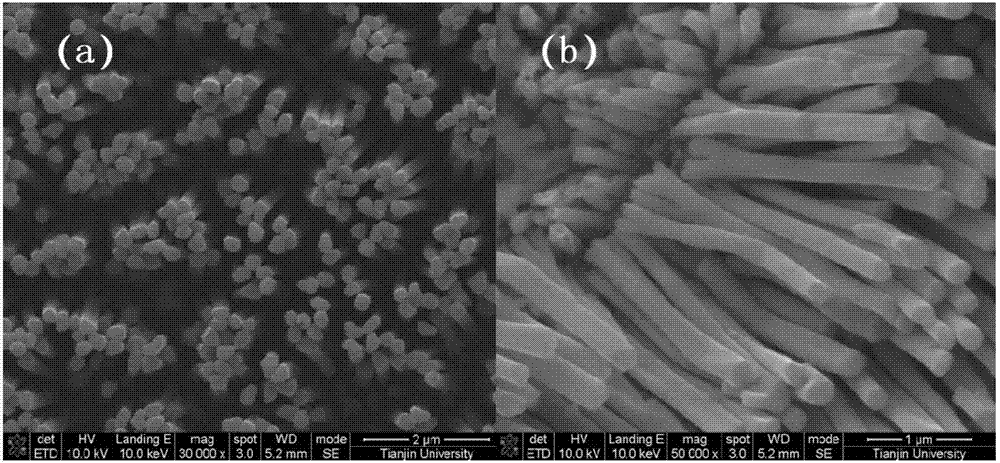

[0048] Ni nanowire arrays were prepared by galvanostatic deposition using an electrochemical workstation, using a three-electrode system, Au electrodes with fixed AAO templates as working electrodes, Pt wire electrodes (1 mm in diameter) as auxili...

Embodiment 3

[0051] Use 1.0 μm, 0.3 μm and 0.05 μm alumina powder to polish the surface of the Au electrode on the suede for 10 min, then use deionized water and ethanol to repeatedly ultrasonically clean it 5 times until the surface of the electrode is mirror-smooth. Cyclic voltammetry was carried out for 15 cycles in phosphate buffered saline until the scanning curve was reproducible. Apply a drop of conductive silver glue on the surface of the Au electrode, spread the conductive silver glue evenly, and quickly fix the gold-sprayed side of the AAO template on the surface of the Au electrode, use insulating silicone rubber to fix the edge of the AAO template, and leave a gap of the size of the Au electrode. AAO templates were left at room temperature for one day to dry naturally.

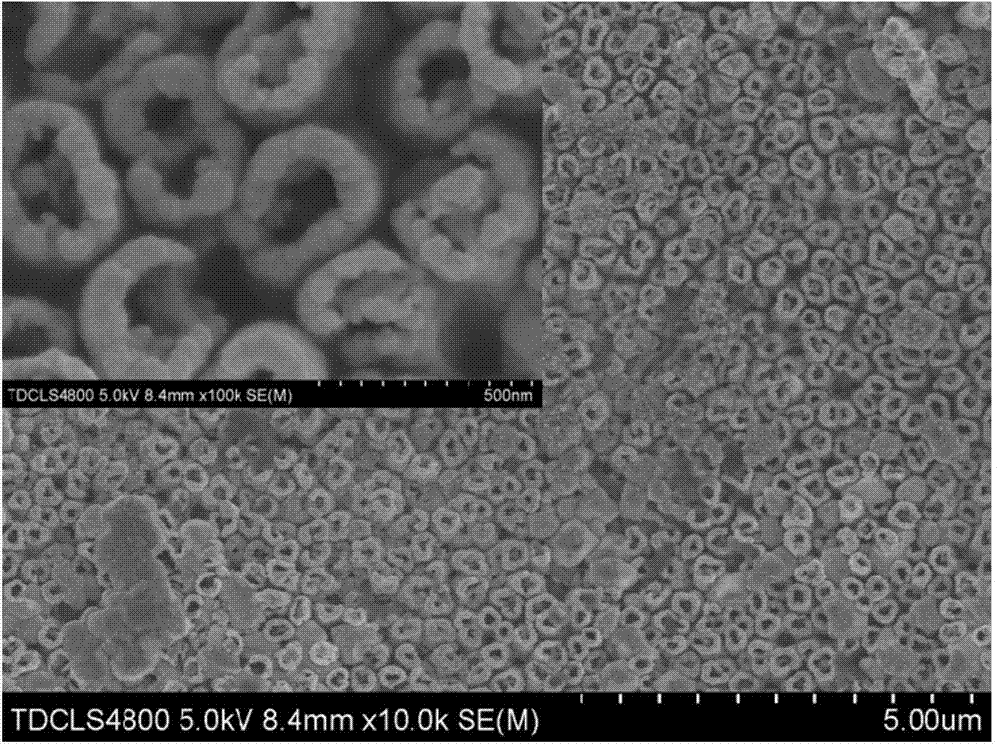

[0052] Ni nanowire arrays were prepared by galvanostatic deposition using an electrochemical workstation, using a three-electrode system, Au electrodes with fixed AAO templates as working electrodes, Pt wire el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com