Pinhole inspection device for can body

A technology for inspection devices and tanks, which is applied in the direction of measuring devices, application of light to test fluid tightness, and optical testing of flaws/defects, etc. It can solve the problem of increased occurrence rate of false detection, lack of detectable light quantity, and functional effects Issues such as not fully explained, achieve the effects of improving shading, preventing interference light from reaching the photodetector side, and uniform friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] One embodiment of the pinhole inspection device for can bodies according to the present invention will be described.

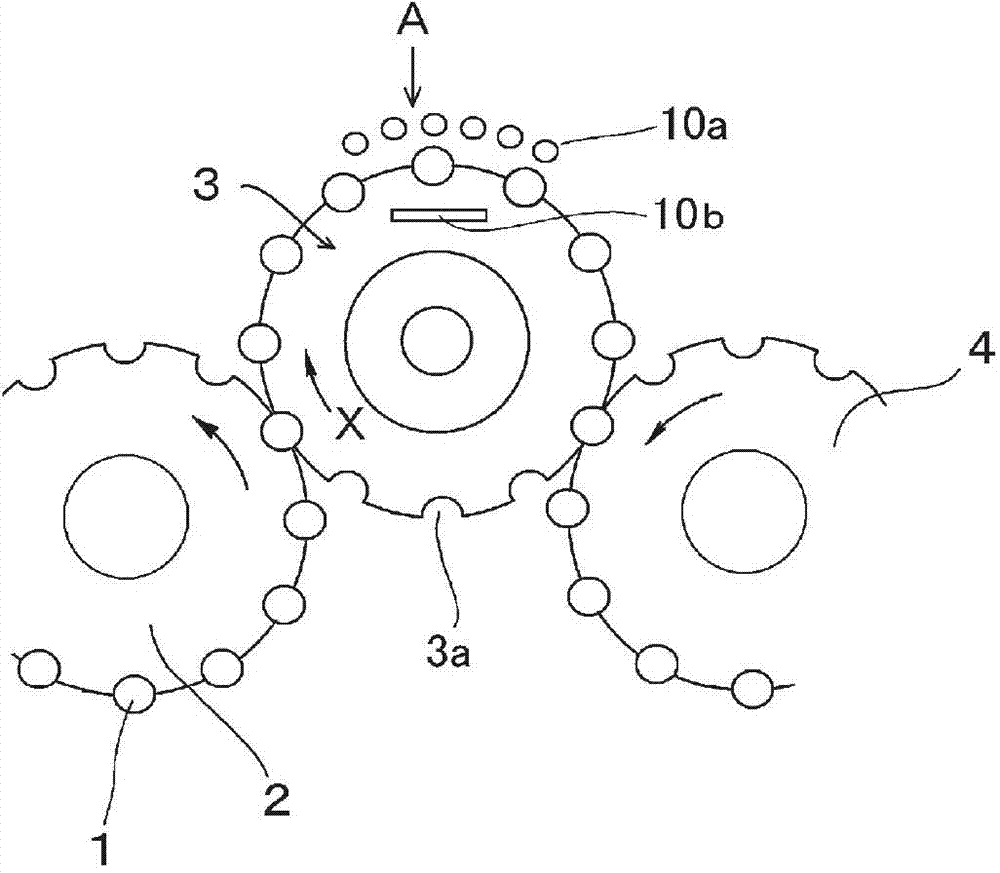

[0046] Such as figure 1 As shown, for the pinhole inspection device for can bodies of the present invention, the can body 1 supplied from the supply turntable 2 to the recess 3a of the holding turntable 3 continuously rotating in the X direction is transported to the upper light source 10a which will be described later. , the inspection station A of the lower light source 10b (hereinafter also referred to as the light source 10 ) and after the good or bad judgment has been carried out, it is sent out to the next process by the sending out turntable 4 .

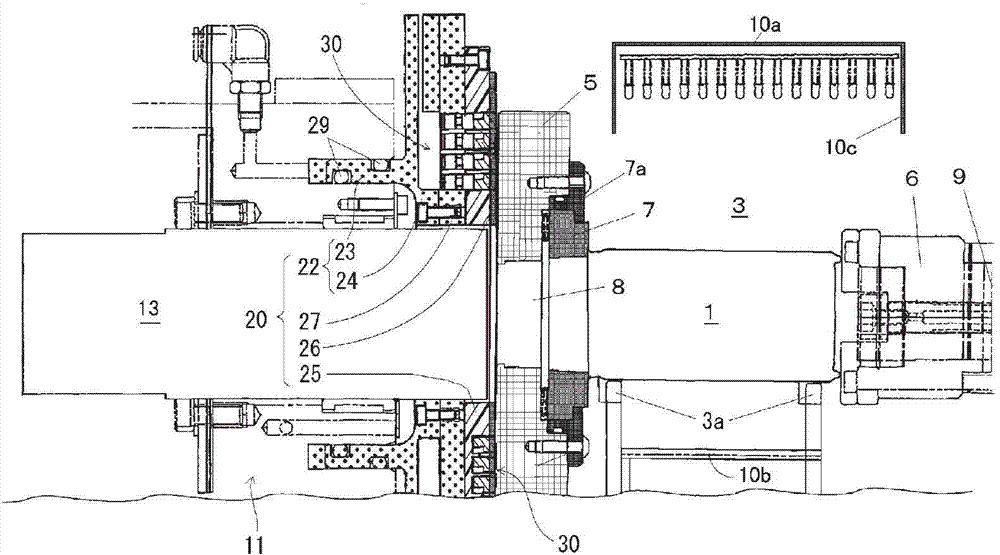

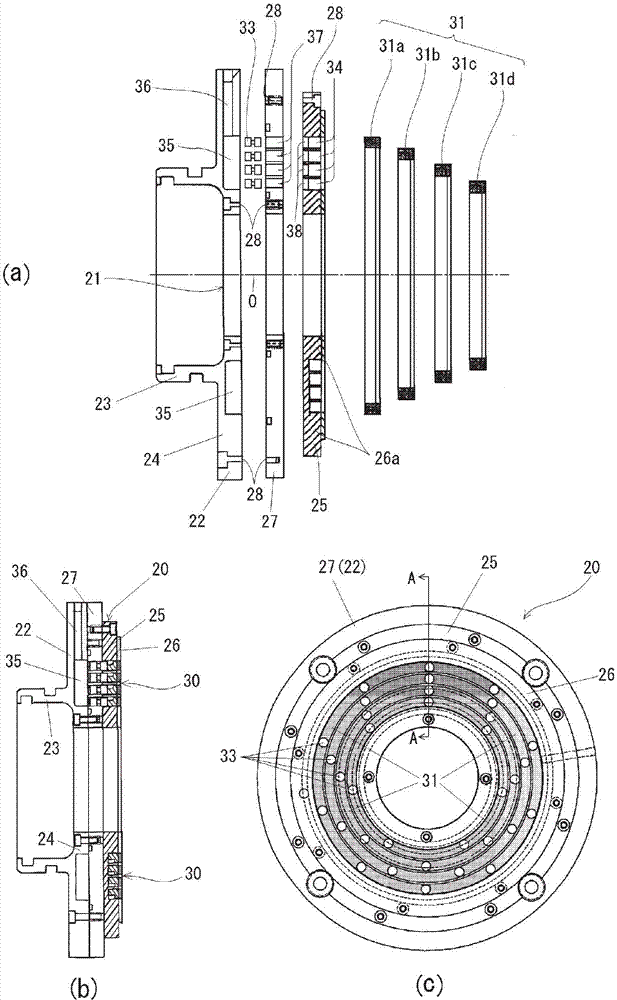

[0047] And, if figure 2 As shown, the pinhole inspection device for cans of the present invention includes a holding turntable 3, a rotating plate 5, a chuck 6, an upper light source 10a, and a lower light source 10b, and the holding turntable 3 and the rotating plate 5 constitute an inspection turnt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com