Preparation technology for novel saccule urethral catheter and novel saccule urethral catheter obtained by adopting same technology

A catheter and balloon technology, applied in the field of new balloon catheters, can solve problems such as difficult insertion, damage to human mucous membrane, and user discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

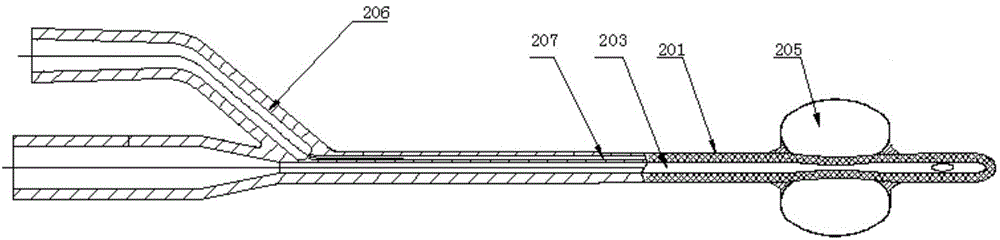

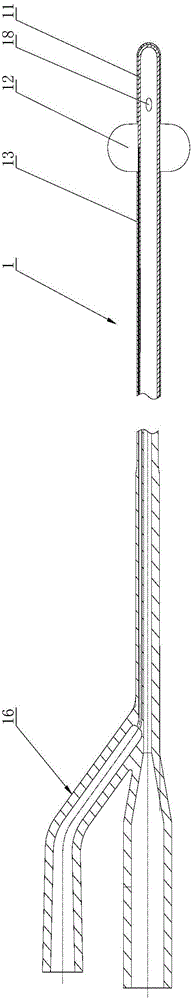

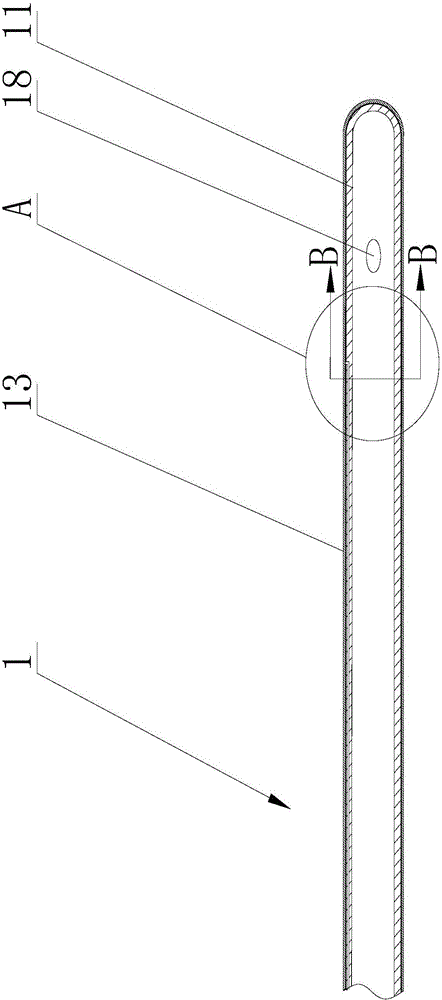

[0063] Such as Figure 2 to Figure 7 As shown, a novel balloon catheter includes a tube body 1, and the tube body 1 includes an inner layer tube 11 and an elastic outer layer 13, and between the inner layer tube 11 and the outer layer 13 is also There is a medium layer 14 for connecting the inner layer tube 11 and the outer layer 13, a balloon filling cavity 17 is opened in the tube wall of the inner layer tube 11, and a row is arranged at the distal end of the tube body 1. The liquid hole 18, the liquid discharge hole 18 communicates with the hollow part 19 of the tube body 1, and also includes an isolation layer 15 arranged at the far end of the tube body 1 to reduce the water adhesion, more specifically, the isolation layer 15 It is preferably composed of a substance capable of dissolving or swelling or dispersing in water. The isolation layer 15 is disposed between the medium layer 14 and the outer layer 13 or the isolation layer 15 is disposed between the inner tube 11 a...

Embodiment 2

[0072] A preparation process for a novel balloon catheter, comprising the steps of:

[0073] Step 1: Prepare the inner layer tube: use a dipping machine to form the inner layer tube by multiple dipping methods, and the thickness of the inner layer tube is 0.3-1.0 mm. The dipping operation is to dip the mold in a natural rubber solution with a total solid content of 50% and a viscosity of 600mPa.S for 20s to 50s. Dipping for 20s to 50s to obtain an inner tube.

[0074] Step 2: Cover the outer layer of the inner tube with a medium layer by dipping. The dipping operation is: dip the inner tube in a medium solution with a solid content of 1% to 30% for 2s, and put the medium layer dry. The formula of the medium layer is: calcium nitrate ethanol solution, and the total solid content of the calcium nitrate is 1% to 30%. Specifically, the formula ratio is: calcium nitrate: 15wt%, absolute ethanol: 85wt%.

[0075] Step 3: Manually or mechanically cover the specified position on th...

Embodiment 3

[0080] A preparation process for a novel balloon catheter, comprising the steps of:

[0081] Step 1: Prepare the inner layer tube: use a dipping machine to form the inner layer tube by multiple dipping methods, and the thickness of the inner layer tube is 0.3-1.0 mm. The dipping operation is to dip the mold in a natural rubber solution with a total solid content of 50% and a viscosity of 600mPa.S for 20s to 50s. Dipping for 20s to 50s to obtain an inner tube.

[0082] Step 2: Cover the outer layer of the inner tube with a medium layer by dipping. The dipping operation is: dip the inner tube in a medium solution with a solid content of 1% to 30% for 2s, and put the medium layer dry. The formula of the medium layer is: calcium nitrate ethanol solution, and the total solid content of the calcium nitrate is 1% to 30%. Specifically, the formula ratio is: calcium nitrate: 15wt%, absolute ethanol: 84wt%, sodium lauryl sulfate: 1wt%.

[0083] Step 3: Manually or mechanically cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com