Greenhouse internal ganoderma lucidum planting dedicated nutrient medium

A nutrient base and Ganoderma lucidum technology, applied in applications, fertilizer mixtures, fertilization devices, etc., can solve the problems of difficult separation of mycelia and insoluble solids in the culture solution, unfavorable ecological environment protection, and consumption of large wood resources. Good layer, good product quality, rich nutrition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

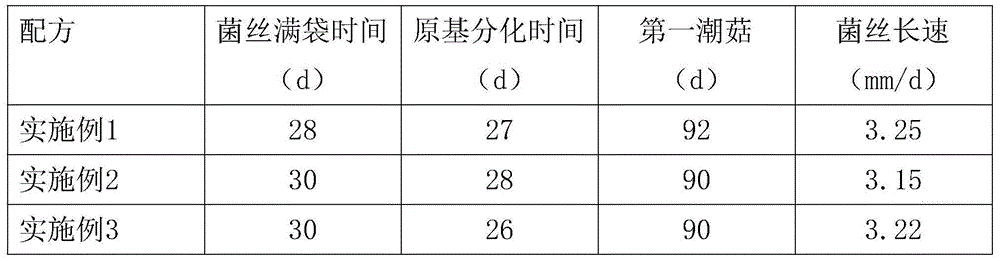

Examples

Embodiment 1

[0032] A special nutrient base for Ganoderma lucidum planting in a shed, which is made of the following components in parts by weight: 10 parts of Sophora japonica powder, 4 parts of purple sweet potato anthocyanin, 5 parts of seaweed micropowder, 0.5 part of cashew nut oil, 5 parts of dry chlorophyll powder, 15 parts of peanut shells, 4 parts of high-strength modified starch, 5 parts of wood chips, 20 parts of mulberry branches, 2 parts of gypsum, 4 parts of sorghum root powder, 2 parts of distiller's grains powder, 2 parts of egg shells, 1 part of tobacco, 2 parts of neem fruit share;

[0033] The above-mentioned dry chlorophyll powder is made of the following components in parts by weight: 10 parts of fresh green tea, 5 parts of cypress leaves, 5 parts of bamboo leaves, 5 parts of spruce, 15 parts of holly, 10 parts of Photinia fruticosa, 20 parts of Euonymus euonymus, 5 parts of sesame leaves, 4 parts of moss, 5 parts of pepper leaves, 5 parts of wheat seedlings, 5 parts o...

Embodiment 2

[0063] A special nutrient base for Ganoderma lucidum planting in a shed, which is made of the following components in parts by weight: 12 parts of Sophora japonica powder, 5 parts of purple sweet potato anthocyanin, 6 parts of seaweed micropowder, 1 part of cashew nut oil, 6 parts of dry chlorophyll powder, 20 parts of peanut shells, 5 parts of high-strength modified starch, 6 parts of wood chips, 25 parts of mulberry branches, 3 parts of gypsum, 5 parts of sorghum root powder, 3 parts of distiller's grain powder, 3 parts of egg shells, 2 parts of tobacco, 3 parts of neem fruit part; during preparation, the above components are mixed evenly, and the pH value is adjusted to 6.5-7.5 with lime powder or citric acid; it can be bagged according to Example 1.

[0064] The above-mentioned dry chlorophyll powder is made of the following components in parts by weight: 10 parts of fresh green tea, 5 parts of cypress leaves, 5 parts of bamboo leaves, 5 parts of spruce, 15 parts of holly, ...

Embodiment 3

[0066] A special nutrient base for Ganoderma lucidum planting in a shed, which is made of the following components in parts by weight: 8 parts of Sophora japonica powder, 3 parts of purple sweet potato anthocyanin, 4 parts of seaweed micropowder, 0.2 part of cashew nut oil, 4 parts of dry chlorophyll powder, 10 parts of peanut shells, 3 parts of high-strength modified starch, 4 parts of wood chips, 15 parts of mulberry branches, 1 part of gypsum, 3 parts of sorghum root powder, 1 part of distiller's grains powder, 1 part of egg shell, 0.5 parts of tobacco, 1 part of neem fruit Parts; during preparation, mix the above components evenly, adjust the pH value to 6.5-7.5 with lime powder or citric acid; carry out bagging according to the method of Example 1.

[0067] The above-mentioned dry chlorophyll powder is made of the following components in parts by weight: 10 parts of fresh green tea, 5 parts of cypress leaves, 5 parts of bamboo leaves, 5 parts of spruce, 15 parts of holly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com