Epoxy resin composite material, preparation method and application

A technology of epoxy resin and composite materials, which is applied in the field of thermal interface materials, can solve problems such as low viscosity, high viscosity, and poor thermal conductivity, and achieve the effects of reducing viscosity, improving interaction, and submitting heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

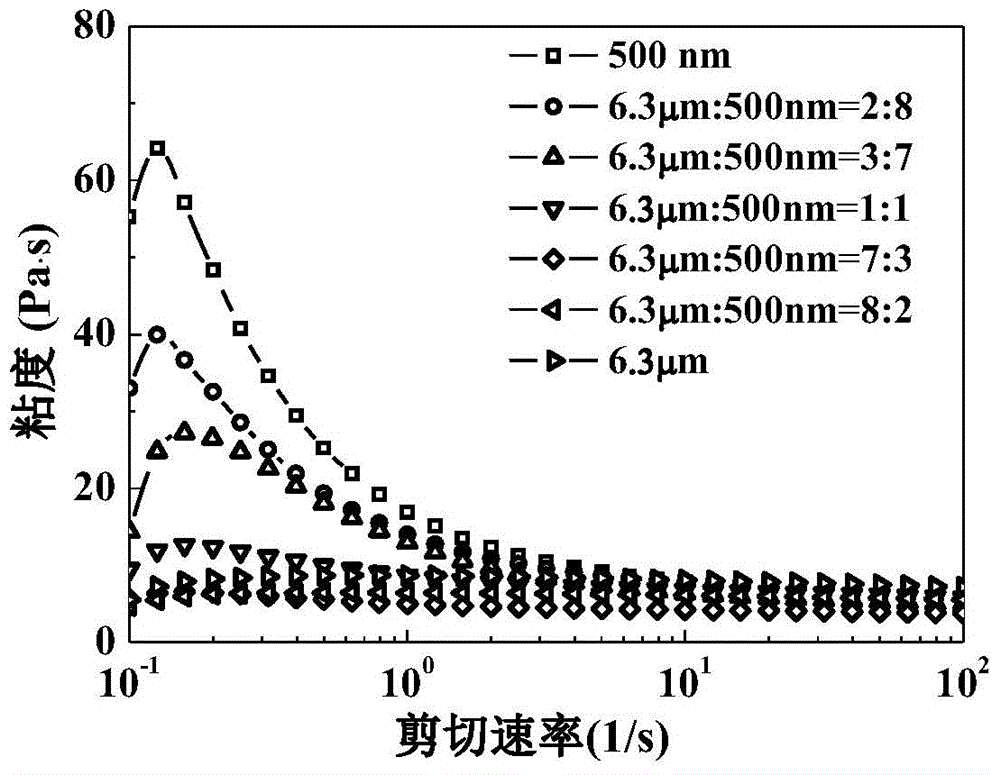

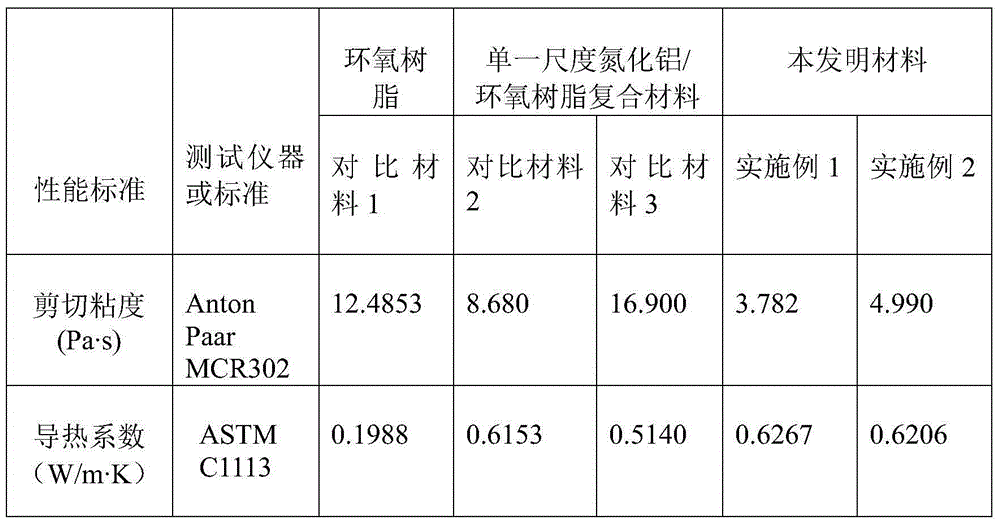

[0042] A kind of epoxy resin composite material, the inorganic filler of 30% volume ratio is uniformly dispersed in epoxy resin, and described inorganic filler comprises large particle diameter inorganic filler and small particle diameter inorganic filler, and the average of described large particle diameter inorganic filler The particle size is 6.3 microns, the average particle size of the small particle size inorganic filler is 500nm, and the volume ratio of the large particle size inorganic filler to the small particle size inorganic filler is 7:3. The inorganic filler with large particle size is aluminum nitride; the inorganic filler with small particle size is aluminum nitride.

[0043]The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, and its thermal conductivity is 0.63W / m·K, and its viscosity is tested according to the test standard Anton Paar MCR302, which is 3.8Pa·s at 25°C.

[0044] An epoxy resin comp...

Embodiment 2

[0053] A kind of epoxy resin composite material, the inorganic filler of 30% volume ratio is uniformly dispersed in epoxy resin, and described inorganic filler comprises large particle diameter inorganic filler and small particle diameter inorganic filler, and the average of described large particle diameter inorganic filler The particle size is 6.3 microns, the average particle size of the small particle size inorganic filler is 500nm, and the volume ratio of the large particle size inorganic filler to the small particle size inorganic filler is 8:2. The inorganic filler with large particle size is aluminum nitride; the inorganic filler with small particle size is aluminum nitride.

[0054] The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, and its thermal conductivity is 0.63W / m·K, and its viscosity is tested according to the test standard Anton Paar MCR302, which is 5.0 Pa·s at 25°C.

[0055] An epoxy resin co...

Embodiment 3

[0075] An epoxy resin composite material, in which an inorganic filler with a volume ratio of 70% is uniformly dispersed in the epoxy resin, and the inorganic filler includes a large particle size inorganic filler and a small particle size inorganic filler, and the average of the large particle size inorganic filler is The particle size is 50 microns, the average particle size of the small particle size inorganic filler is 500 nm, and the volume ratio of the large particle size inorganic filler to the small particle size inorganic filler is 9:1. The inorganic filler with a large particle size is alumina; the inorganic filler with a small particle size is silicon dioxide.

[0076] The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, and its thermal conductivity is 1.1 W / m·K, and its viscosity is tested according to the test standard Anton Paar MCR302, which is 19.2 Pa·s at 25°C.

[0077] An epoxy resin composite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com