A kind of method for preparing aviation fuel antiwear agent

A technology for aviation fuel and antiwear agent, which is applied in the preparation of sulfonic acid, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of increased corrosion of jet fuel, unstable product quality, affecting the color index of aviation fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] To prepare mixed fatty acids:

[0060] (1) Accurately weigh 100 g of sunflower oil in a 250 mL three-neck flask.

[0061] (2) Add 40g KOH, 80g deionized water (or 40ml 50% KOH solution) and 160ml 95% ethanol solution.

[0062] (3) Stir and reflux saponification for 2 hours in a glycerin bath at 90°C to obtain a saponification liquid (take a small amount of saponification liquid and dissolve it in water, and if there is no oil layer on standing, the saponification is complete).

[0063] (4) After the saponified solution is cooled to room temperature, add dilute hydrochloric acid to acidify to pH=2-3, and extract the oil phase with a small amount of petroleum ether.

[0064] (5) After acidification, wash with deionized water until neutral, and separate the liquids. The upper oily phase was dried with anhydrous sodium sulfate and left to stand overnight.

[0065] (6) Remove anhydrous sodium sulfate by filtration.

Embodiment 2

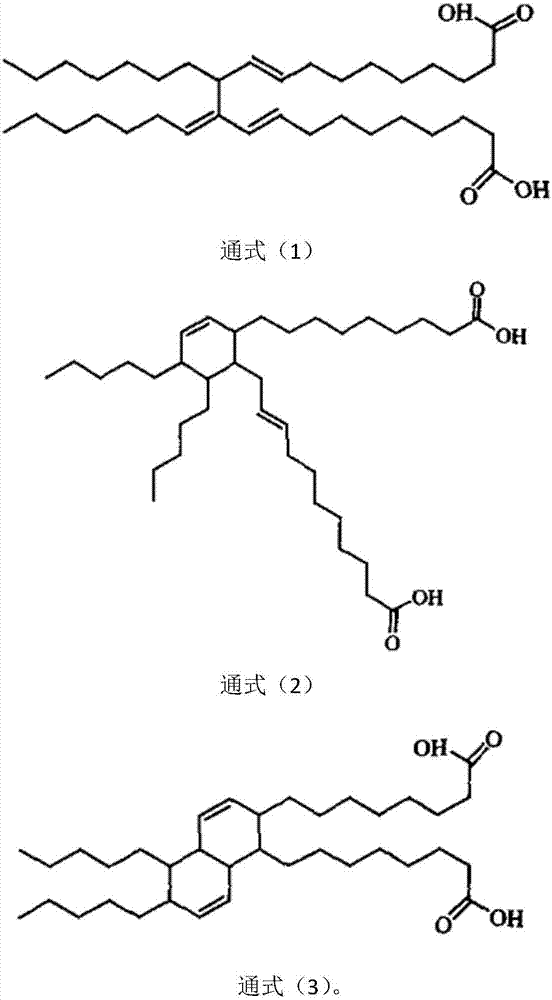

[0068] Synthesis of C36 unsaturated fatty acid dimers:

[0069] (1) Place the mixed fatty acid obtained in Example 1 in the autoclave as a raw material, then add 12% catalyst and 1% auxiliary agent, based on the mass of the above mixed fatty acid, install the autoclave, and check the airtightness properties, wherein the catalyst is activated clay, and the auxiliary agent is lithium carbonate;

[0070] (2) purge the autoclave three times with nitrogen, discharge the air in the autoclave, then fill the autoclave with nitrogen to 2.0MPa, and close the autoclave inlet valve;

[0071] (3) be heated to reaction temperature 240 ℃ under the condition of stirring, promptly start counting when reaching reaction temperature, as reaction zero point;

[0072] (4) After 6 hours of reaction, stop heating, place the autoclave still body in cold water, make the still body rapidly drop to room temperature, open the still, and pour out the reaction product;

[0073] (5) Dilute the crude produc...

Embodiment 3

[0078] Synthesis of C36 unsaturated fatty acid dimers:

[0079] (1) Put linoleic acid in the autoclave as raw material, then add 12% catalyst and 1% auxiliary agent, based on the mass of the above-mentioned linoleic acid, install the autoclave, and check the air tightness, wherein The catalyst is activated clay, and the auxiliary agent is lithium carbonate;

[0080] (2) purge the autoclave three times with nitrogen, discharge the air in the autoclave, then fill the autoclave with nitrogen to 2.0MPa, and close the autoclave inlet valve;

[0081] (3) be heated to reaction temperature 230 ℃ under the condition of stirring, promptly start counting when reaching reaction temperature, as reaction zero point;

[0082] (4) After 6 hours of reaction, stop heating, place the autoclave still body in cold water, make the still body rapidly drop to room temperature, open the still, and pour out the reaction product;

[0083] (5) Dilute the crude product with an equal volume of petroleum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com