Method for preparing centrifugal ventilator impeller with carbon fiber composite materials

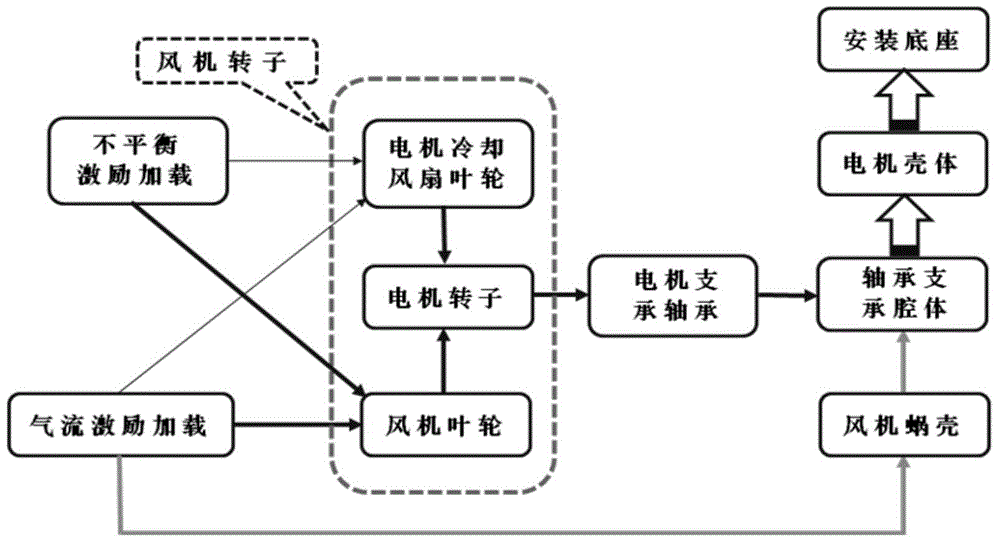

A composite material and centrifuge preparation technology, which is applied in liquid fuel engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problem of increasing unbalanced excitation of fan rotors, poor vibration attenuation performance, and increased fan vibration To improve the anti-vibration potential, small vibration response, and reduce unbalanced excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

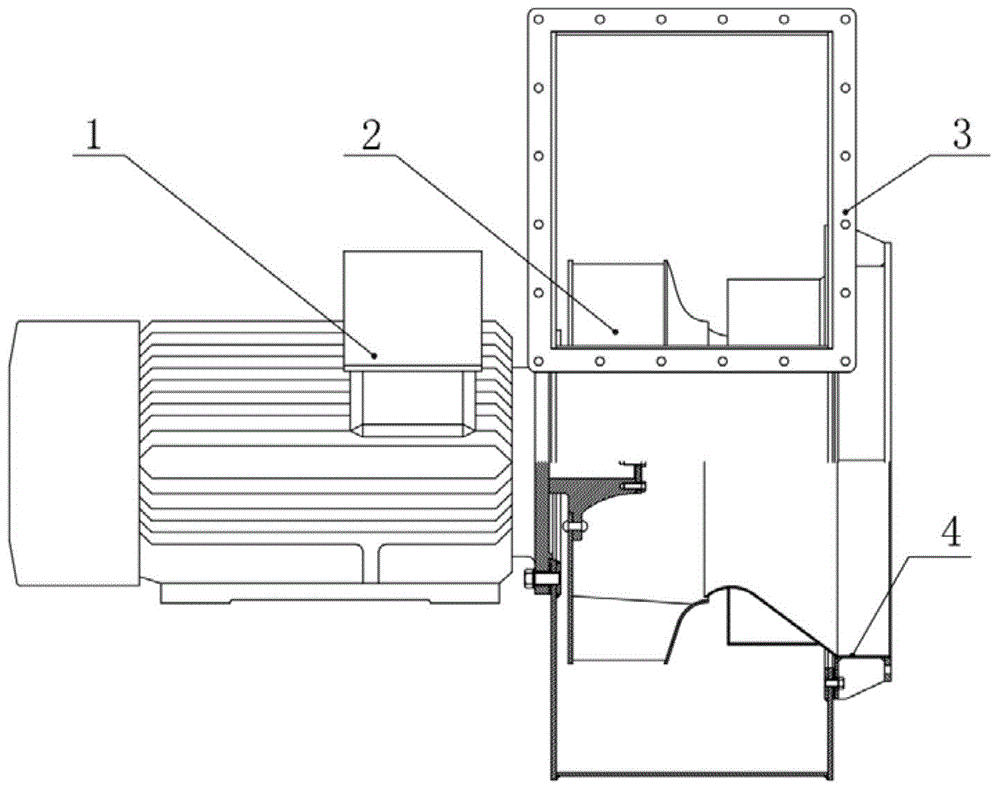

[0041] The technical solutions of the present invention will be further explained below through specific implementations in conjunction with the drawings.

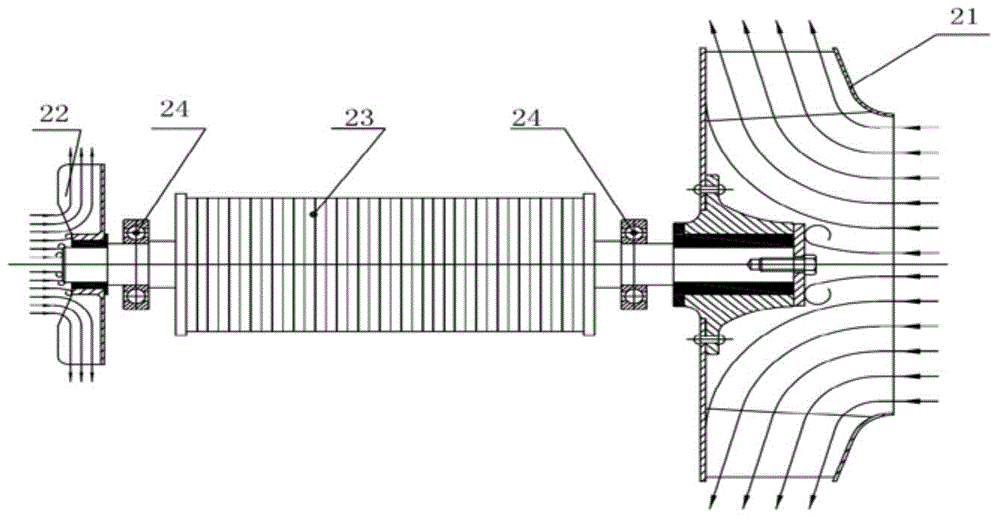

[0042] A method for preparing the impeller of a centrifugal fan using carbon fiber composite materials is to decompose the impeller into three independent parts, namely the wheel cover 6, the blade 7 and the disc 8, which are formed separately, and then the three parts are assembled into a whole; The separate forming method of the wheel cover, blade and wheel disc is as follows:

[0043] (1) The forming mold of the wheel cover 6 is a steel mold. Laying sequence starts from the convex surface of the mold. Two layers of T300 orthogonal carbon fiber cloth prepreg are laid on the bottom of the wheel cover, each layer is 0.212mm thick; 16 layers of T700 uniaxial carbon fiber cloth prepreg are laid in the middle, each layer thickness is 0.125mm, Laying order is as follows [0° / 90° / 45° / -45° / -45° / 45° / 90° / 0°], the above-mentioned layup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com