Method for determining surface roughness, optical constant and thickness of optical thin film simultaneously

A technology of surface roughness and optical constant, applied in optical constant and thickness, at the same time to determine the surface roughness of optical film, can solve the problem of obtaining the optical constant and thickness of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

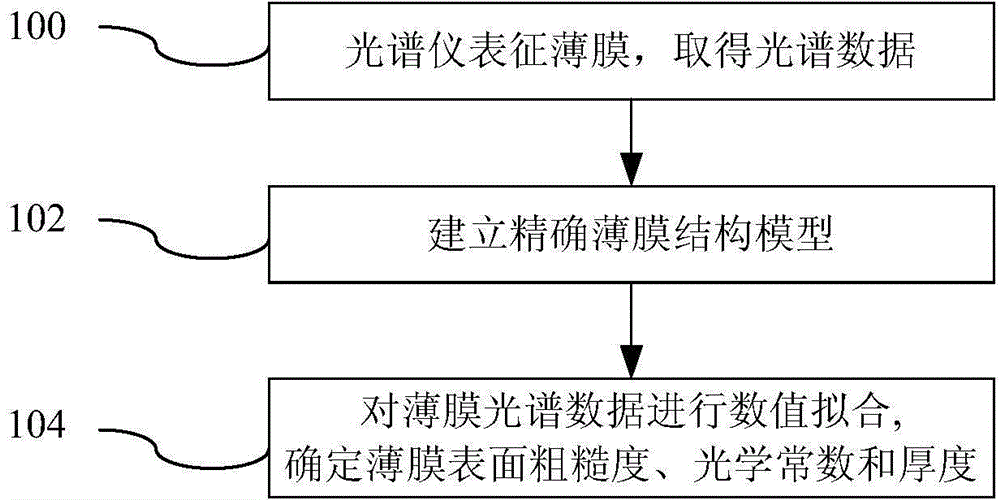

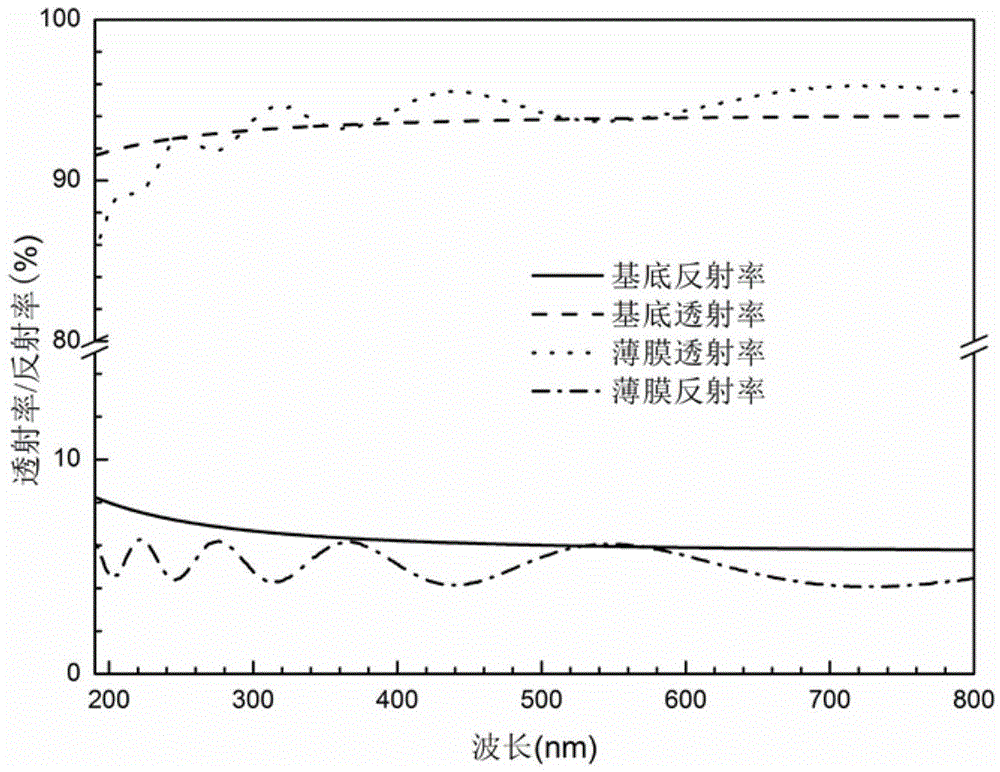

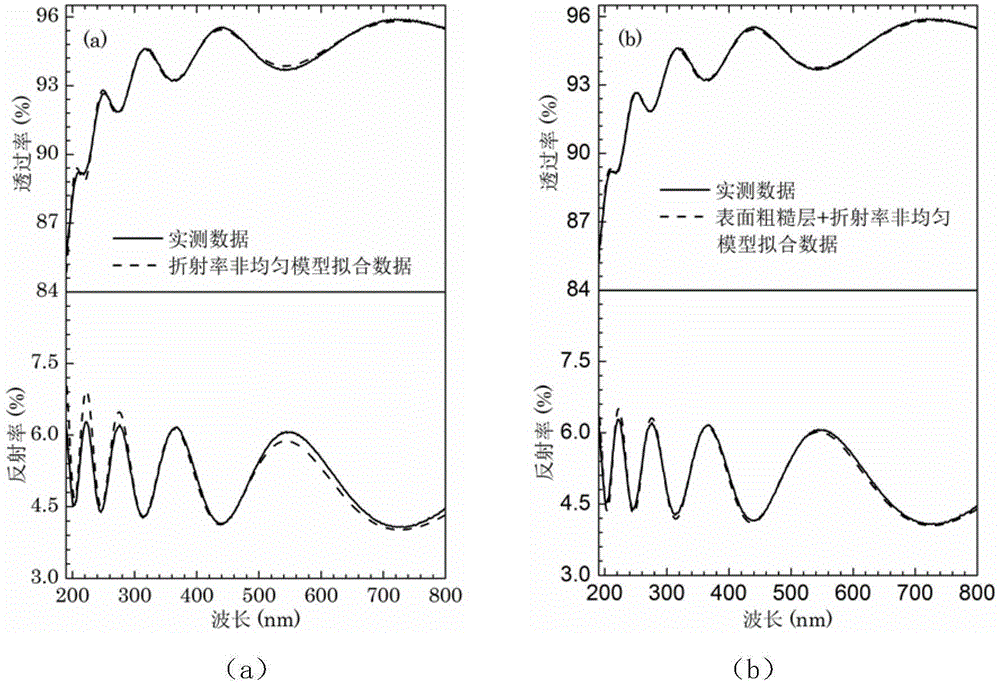

[0035] figure 1It is a schematic flow chart of simultaneously determining the surface roughness, optical constant and thickness of an optical film by photometry in the present invention. The specific implementation steps are as follows: First, use a spectrophotometer to measure the spectral data of the optical thin film; then establish an accurate thin film structure model that can reflect the physical reality of the thin film based on the measured spectral data of the thin film; The surface structure is used to reflect the physical reality of the film. According to the characteristics of each part, the film body structure model and the film surface structure model are respectively established; the optical transmission matrix of the corresponding structure model is given, and the optical transmission matrix of the entire film is obtained from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com