Porous ceria nanorod composite structure and preparation method of enzyme solution based on structure, as well as enzyme-linked immunosorbent assay (Elisa) application

A technology of ceria and composite structure, which is applied in the field of nanomaterials, can solve the problems of simulating the catalytic ability of enzymes, such as the large influence of temperature and difficulties in practical application, and achieve the effects of enhanced sensitivity, easy storage and transportation, and good reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Second, the present invention provides a method for preparing a ceria nanorod simulated enzyme solution, comprising:

[0038] First mix the ceria nanorods, antigen or antibody, and coating buffer evenly, and incubate at a constant temperature; then centrifuge to remove free antigen or antibody to obtain ceria nanorods coated with antigen or antibody; finally Resuspended to prepare ceria nanorods simulated enzyme solution.

[0039] Among them, the pellet can be resuspended with deionized water or coating buffer. The concentration of ceria nanorods in the resuspended ceria nanorods simulated enzyme solution is 0.1-10mg / mL, such as 0.2mg / mL, 0.3mg / mL, 0.5mg / mL, 1mg / mL, 5mg / mL Or 10 mg / mL, more preferably 1 mg / mL.

[0040] Preferably, the coating buffer in the step is selected from a buffer solution containing bovine serum albumin (BSA); wherein, the buffer solution can be Tris buffer (Tris), phosphate buffer (PBS) and hydroxyl One or more of ethylpiperazine ethylsulfuri...

Embodiment 1

[0062] Embodiment 1: Preparation and purification of ceria nanorods

[0063] The ceria nanorods in the present invention can be obtained by methods well known to those skilled in the art. In the present invention, we firstly prepare the precursor of cerium oxide nanorods, and then obtain pure ceria nanorods by hydrothermal method.

[0064] Preparation of ceria nanorods: 5 mL of cerium nitrate aqueous solution (0.8 M) and 75 mL of NaOH aqueous solution (6.4 M) were mixed at room temperature for 30 min, and then hydrothermally treated at 100° C. for 24 h. After repeated washing with water and ethanol three times and drying, redisperse in water (2mg / mL), and hydrothermally treat at 180°C for 12h. Centrifuge at 12000rpm for 10min, remove the supernatant, and dry overnight at 60°C for later use.

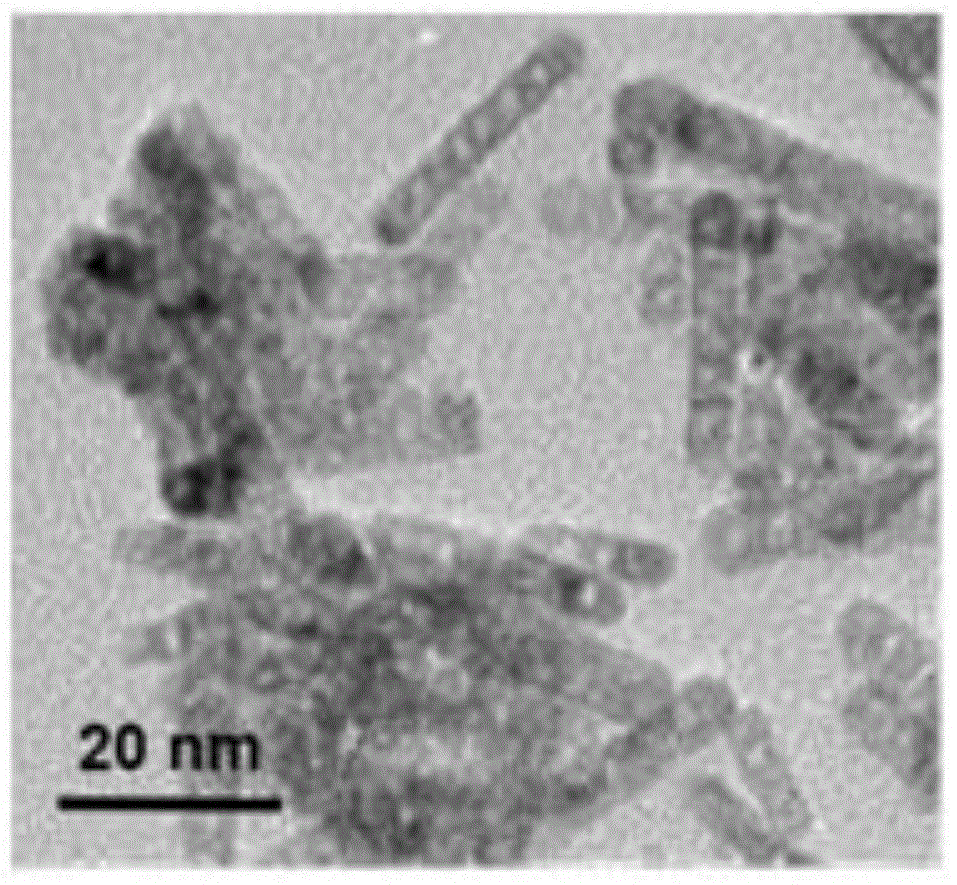

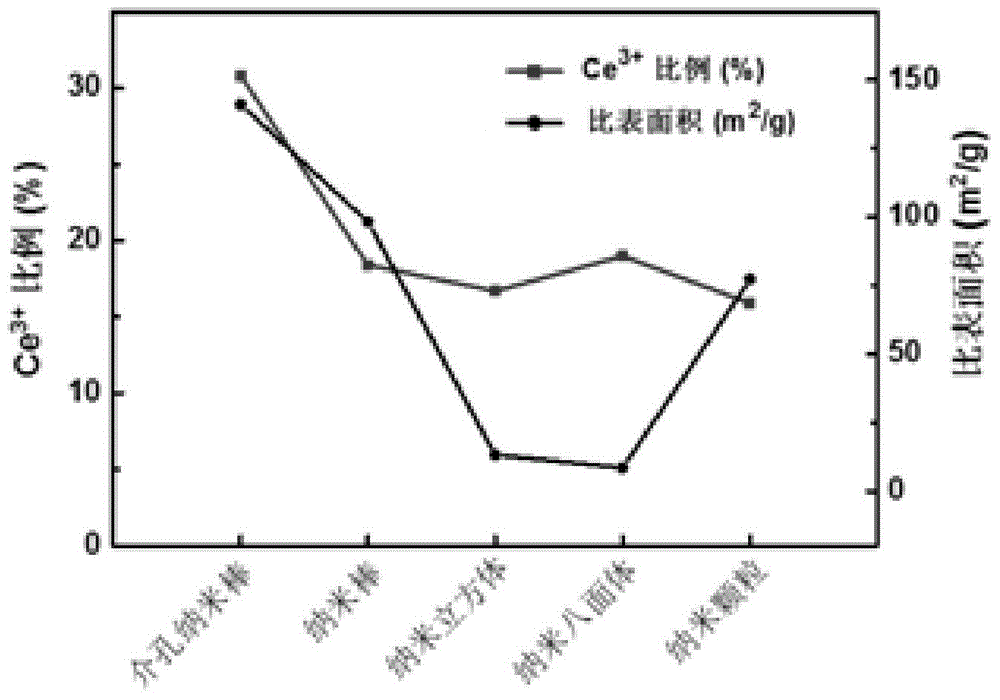

[0065] TEM morphology of ceria nanorods and the corresponding specific surface area and Ce 3+ Scale maps such as figure 1 and figure 2 shown. From figure 1 It can be seen that the...

Embodiment 2

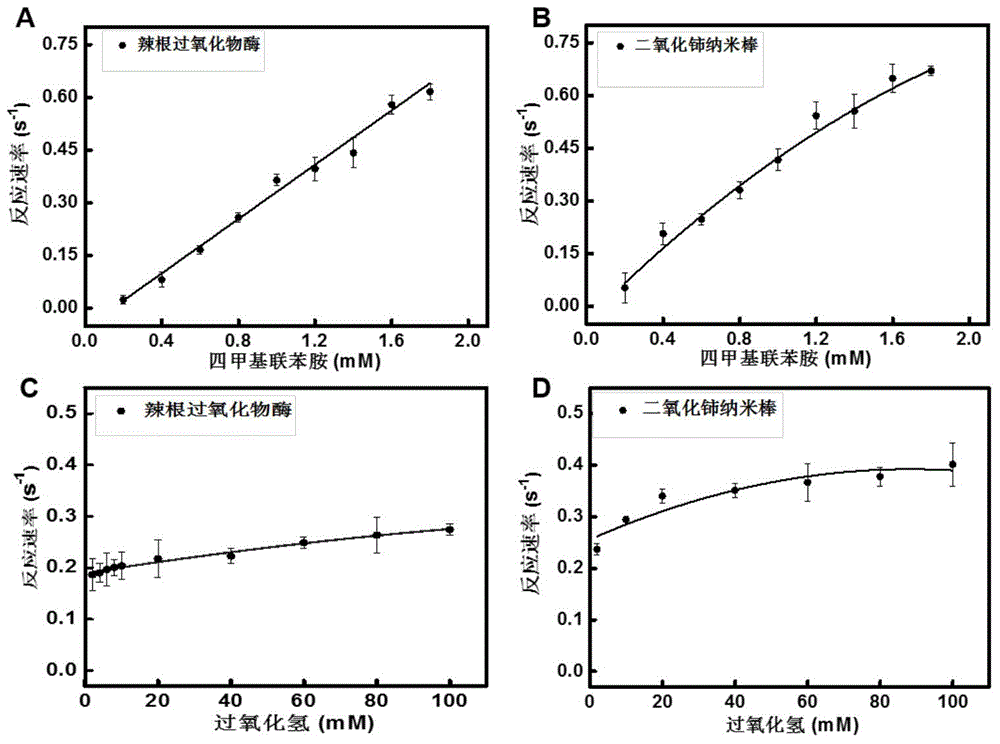

[0073] Embodiment 2: Enzyme kinetic parameter analysis

[0074] The reaction kinetics were investigated by monitoring the change of the absorbance of the oxidation product of 3,3',5,5'-tetramethylbenzidine. Use the continuous monitoring mode to measure every 1s interval. The test conditions were as follows: the concentration of ceria nanorods was 0.2 μg / mL, the concentration of HRP as a control was 1 ng / mL, 1.0 mL of 0.2M acetic acid buffer solution with pH 4.0, and the reaction temperature was set at 25°C. With 3,3',5,5'-tetramethylbenzidine as substrate, H 2 0 2 The concentration is fixed at 100mM; when H 2 o 2As the substrate, the concentration of TMB was fixed at 0.8mM. The apparent kinetic parameters refer to the Lineweaver-Burk equation: l / V=(K m / V max )(1 / [C])+1 / V max get. where V is the reaction velocity, V max is the maximum reaction velocity, [C] is the substrate concentration, K m is the Michaelis constant.

[0075] The kinetic parameters obtained are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com