Esterification catalyst for preparing biological diesel oil by animal plant lipid and application method

A technology of animal and vegetable oils and esterification reactions, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of large dosage, catalyst poisoning, complicated post-treatment process, etc., and reduce the temperature of esterification reaction , Esterification reaction time is shortened, and the effect of reducing processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Prepare biodiesel with waste oil extracted from catering industry garbage as raw material, take the components of the catalyst by the following weights and mix them to prepare the esterification catalyst: A component zinc sulfate 2.0kg, B component tetraammonium sulfate copper 0.5kg kg, C component cadmium oxide 0.15kg, aluminum sulfide 0.35kg.

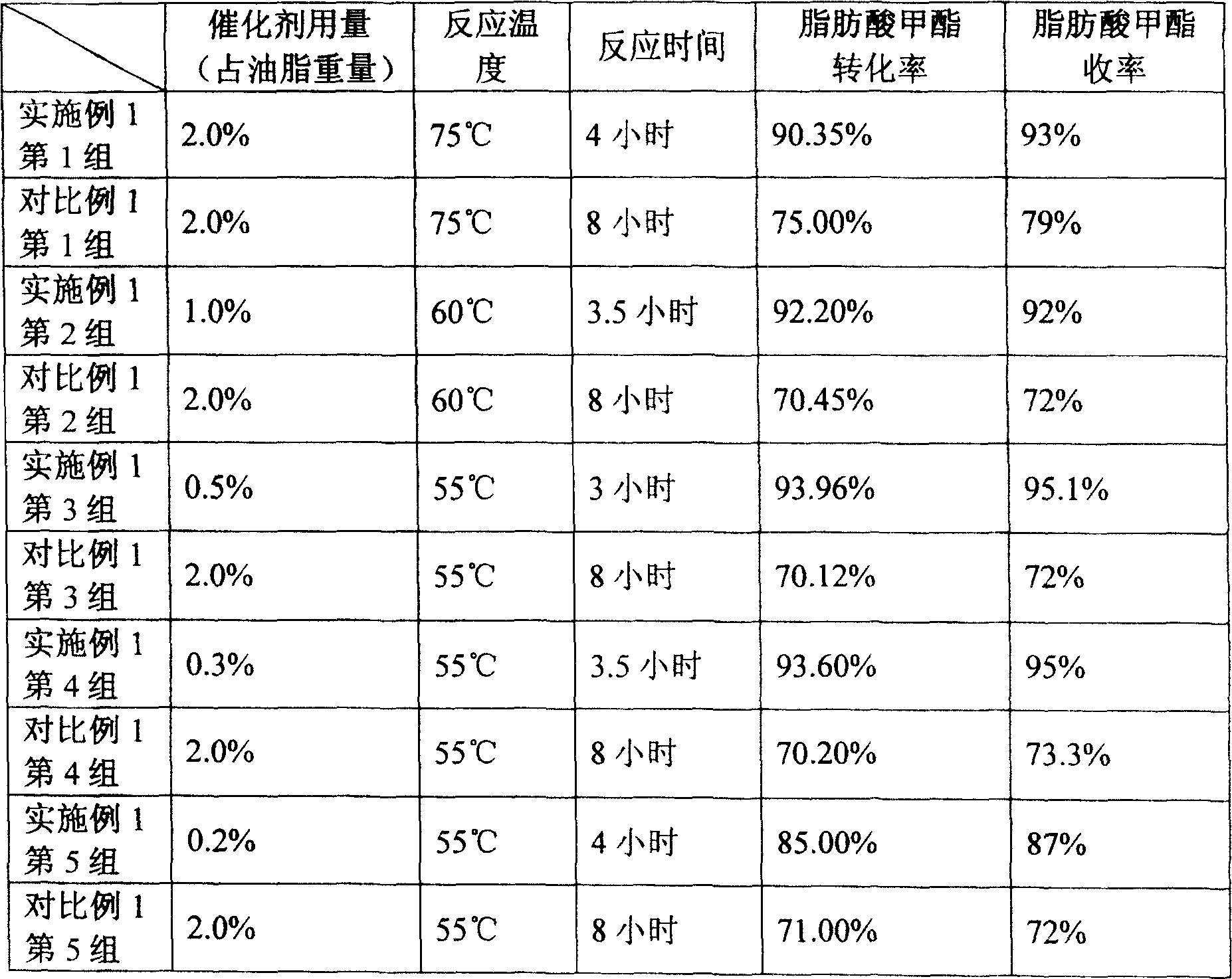

[0030] First add sulfuric acid to the waste oil for acidification, then use pH test paper to detect its pH value is less than 4, then wash with water to remove impurities in the oil, and vacuum dehydrate, the dehydrated oil is added according to the molar ratio of oil: methanol = 1:4 Methanol, and adding different amounts of esterification catalysts to carry out 5 groups of esterification tests under different reaction conditions. Distillation recovers methanol and separates the oil phase from the water phase. The fraction of fatty acid methyl esters obtained by vacuum distillation of the oil phase is biodiesel. The c...

Embodiment 2

[0035] Embodiment 2 uses rapeseed pressed oil as the raw material for preparing biodiesel, and the components and weight ratio of the esterification catalyst are as follows: 1.0 kg of zinc sulfate for A component, 0.5 kg of aluminum sulfate, and tetraammine copper sulfate for B component 0.8kg, C component cadmium oxide 0.10kg, aluminum sulfide 0.30kg.

[0036] First add phosphoric acid in rapeseed oil and carry out acidification, make its pH value less than 4, then wash and remove the impurity in the oil, and vacuum dehydration, the oil after dehydration adds methanol by the molar ratio of oil: methanol=1: 4.5, heats up to At 40°C, add an esterification catalyst accounting for 0.3% of the weight ratio of animal and vegetable oils, and continue to heat up to 55-60°C for 3 hours of transesterification; distill and recover methanol and separate the oil phase from the water phase, and the oil phase is subjected to vacuum The fatty acid methyl ester fraction obtained by distillati...

Embodiment 3

[0039] Embodiment 3 Use animal lard as the grease raw material to prepare biodiesel, take the components of the catalyst according to the following weight ratios and mix and prepare the esterification reaction catalyst: 1.0 kg of aluminum sulfate of component A, 0.2 kg of tetraammonium sulfate complexed copper of component B kg, component C cadmium oxide 0.10kg, aluminum sulfide 0.20kg.

[0040] First add sulfuric acid to animal lard for acidification, make its pH value less than 2, then wash with water to remove impurities in the oil, and vacuum dehydrate, add methanol to the oil after dehydration according to the molar ratio of oil: methanol = 1:5, and heat up to Add an esterification catalyst accounting for 0.5% by weight of animal and vegetable oils at 40°C, continue to heat up to 55-60°C for 3 hours of transesterification; distill and recover methanol and separate the oil phase from the water phase, and vacuum the oil phase The fatty acid methyl ester fraction obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com