Manufacturing method for graphene touch screen sensor

A technology of a touch screen sensor and a manufacturing method, which is applied to instruments, data processing input/output process, electrical digital data processing, etc., can solve problems such as poor printing adhesion, achieve good electrical connection, and solve problems of poor printing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a graphene touch screen sensor, taking a substrate transferred with a graphene film as an object, removing the graphene film in the electrode printing area in advance, leaving only the graphene overlapping area, the overlapping area is the electrode printing area and the graphene In the area where the films overlap, the metal electrode paste is printed on the electrode printing area where the graphene film is removed, and the sensor is formed after patterning.

[0031] Wherein, the substrate in the substrate transferred with the graphene film is a plastic or glass substrate.

[0032] The manufacturing method specifically includes the following steps:

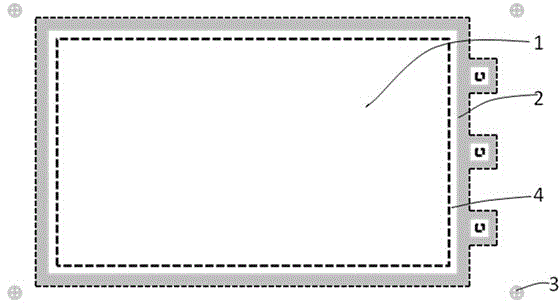

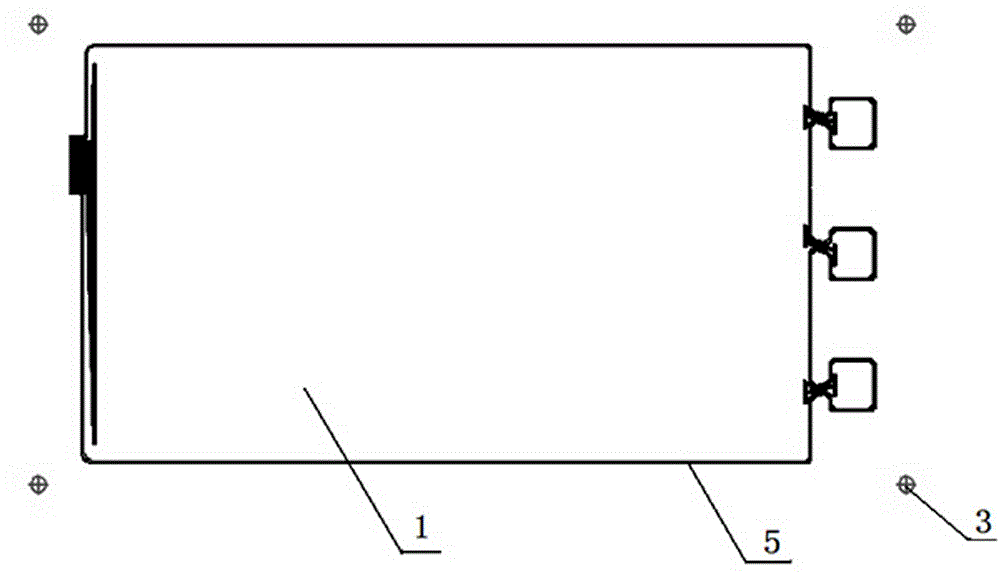

[0033] Such as figure 1 and figure 2 as shown, figure 1 All within the dotted line is the electrode printing area, where the shaded area is the area where graphene is removed, and the shaded area inside the dotted line is the graphene overlapping area. figure 2 In the metal electrode area ...

Embodiment 2

[0044] The specific preparation steps of the graphene touch screen sensor in this embodiment are as follows:

[0045] (1) Taking the PET substrate with the transferred 2-layer graphene film as the object, and using the four surrounding targets as the reference, the graphene in the electrode printing area is removed by laser direct writing process, revealing the base material, and retaining the graphene bonding pick up area.

[0046] (2) Clean the surface of the graphene film by blowing dust with compressed gas;

[0047] (3) Use a screen printing machine to overprint the silver paste to the surface area of the substrate where the graphene has been removed, and ensure that the metal electrode paste can overlap the edge of the graphene with a lap width of 0.5mm to form a good electrical connection;

[0048] (4) Use a dust-free oven to bake the silver paste, the baking temperature is 135 degrees, and the baking time is 60 minutes, so that it can meet the requirements of the po...

Embodiment 3

[0051] The specific preparation steps of the graphene touch screen sensor in this embodiment are as follows:

[0052] (1) Take the glass substrate with one layer of graphene film transferred as the object, and use the mask plate combined with the plasma etching process to remove the graphene in the electrode printing area and reveal the substrate material, based on the four surrounding targets. Preserve the graphene overlap area.

[0053] (2) Clean the surface of the graphene film by blowing dust with compressed gas;

[0054] (3) Use a screen printing machine to overprint the gold paste to the surface area of the substrate from which the graphene has been removed, and ensure that the metal electrode paste can overlap the edge of the graphene with a lap width of 0.4 mm to form a good electrical connection;

[0055] (4) The gold paste is baked in a dust-free oven, the baking temperature is 140 degrees, and the baking time is 80 minutes, so that it can meet the requirements of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com