A kind of preparation method of LED photonic crystal

A technology of photonic crystals and light beams, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult photonic crystal nanoprocessing technology, unfavorable large-scale production, complex process steps, etc., to achieve increased luminous power, low processing, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

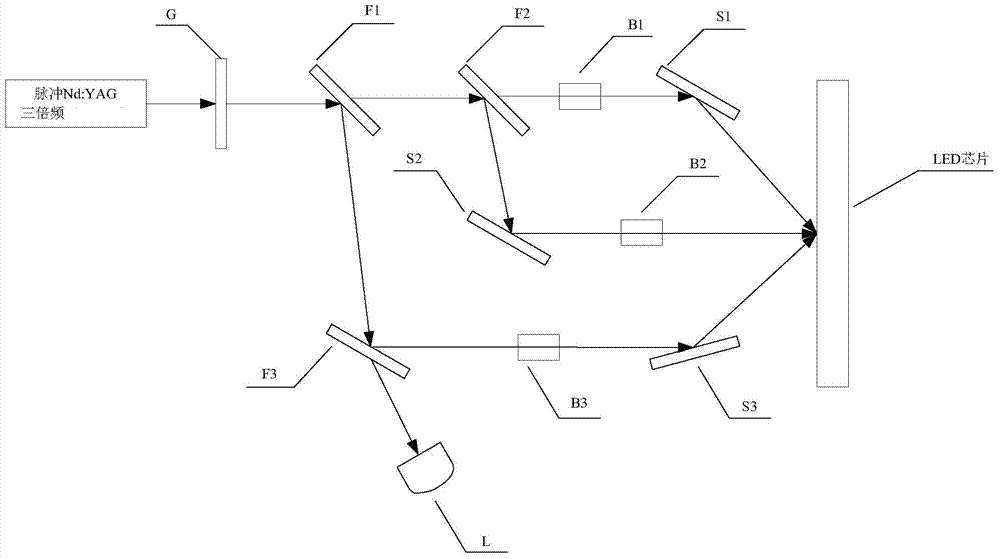

[0022] Such as figure 1 As shown, using the triple frequency laser beam (355nm) of Nd:YAG laser as the direct etching laser, on the GaN chip, photonic crystals with different periods and different depths of the triangular lattice were prepared on the ITO layer. After the frequency-doubled laser beam passes through the diaphragm G, it is divided into a first beam and a second beam through the first beam splitter F1; the first beam is divided into a third beam and a fourth beam through the second beam splitter F2; The second beam is divided into a fifth beam and a sixth beam by the third beam splitter F3; the sixth beam is directly input to the optical power meter L for detecting and monitoring the power of the Nd:YAG laser. The third light beam, the fourth light beam and the fifth light beam are respectively modulated by polarizers and reflectors and converged on the transparent electrode film of the LED chip at the same time, that is, the third light beam passes through the fi...

Embodiment 2

[0024] Such as figure 1 As shown, the frequency tripled laser beam of Nd:YAG laser is used as the direct etching laser, and on the GaN chip, photonic crystals with different periods and different depths of the triangular lattice are prepared on the ITO layer, and the frequency tripled laser After the beam passes through the aperture G, it is divided into a first beam and a second beam through the first beam splitter F1; the first beam is divided into a third beam and a fourth beam through the second beam splitter F2; the second beam is passed through The third beam splitter F3 is divided into a fifth light beam and a sixth light beam; the sixth light beam is directly input to the optical power meter L for detecting and monitoring the power of the Nd:YAG laser. The third light beam, the fourth light beam and the fifth light beam are respectively modulated by polarizers and reflectors and converged on the transparent electrode film of the LED chip at the same time, that is, the ...

Embodiment 3

[0025] Such as figure 1 As shown, the frequency tripled laser beam of Nd:YAG laser is used as the direct etching laser, and on the GaN chip, photonic crystals with different periods and different depths of the triangular lattice are prepared on the ITO layer, and the frequency tripled laser After the beam passes through the aperture G, it is divided into a first beam and a second beam through the first beam splitter F1; the first beam is divided into a third beam and a fourth beam through the second beam splitter F2; the second beam is passed through The third beam splitter F3 is divided into a fifth light beam and a sixth light beam; the sixth light beam is directly input to the optical power meter L for detecting and monitoring the power of the Nd:YAG laser. The third light beam, the fourth light beam and the fifth light beam are respectively modulated by polarizers and reflectors and converged on the transparent electrode film of the LED chip at the same time, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com