Patents

Literature

34results about How to "Cycle controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

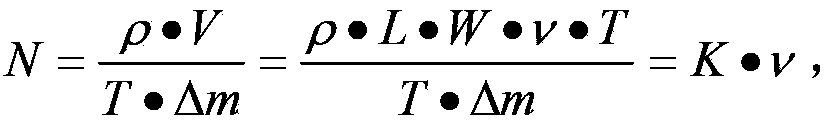

Full-automatic commercial pure titanium smelting method adopting electron beam cold hearth furnace

The invention relates to a full-automatic TA1 smelting method adopting an electron beam cold hearth furnace and belongs to the technical field of production engineering application. The production method comprises the following steps: drying and putting titanium sponge into an Archimedean screw tube which is mounted into a feeding system of an electron beam cold hearth melting furnace (EB furnace for short), wherein different rotary speeds are set; when the degree of vacuum of the feeding system reaches 0.4-0.8 Pa and the degree of vacuum of a main smelting cold hearth reaches 0.05-0.8 Pa, starting the feeding system to feed the titanium sponge into the smelting cold hearth of a main smelting chamber; triggering an electron gun to melt the titanium sponge into liquid titanium which flows through a primary refining cold hearth and a main refining cold hearth and then into a rectangular withdrawing crucible; controlling the rotary speed of the Archimedean screw tube to control the feeding speed and scanning patterns so as to control the melting speed, and the ingot pulling rate thereby realizing full-automatic control. The method has the advantages of good ingoting quality, high one-step yield, low manufacturing cost, controllable production period, simplicity in operation, energy conservation, environmental protection and high repeatability.

Owner:YUNNAN TITANIUM IND

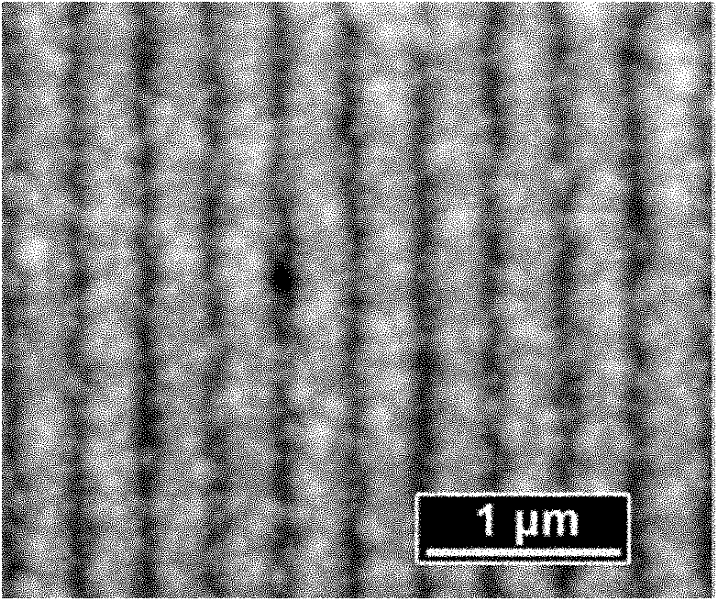

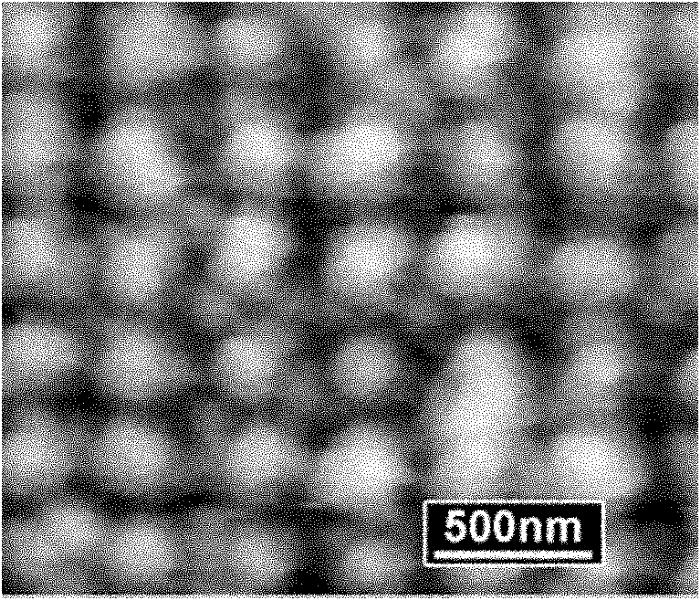

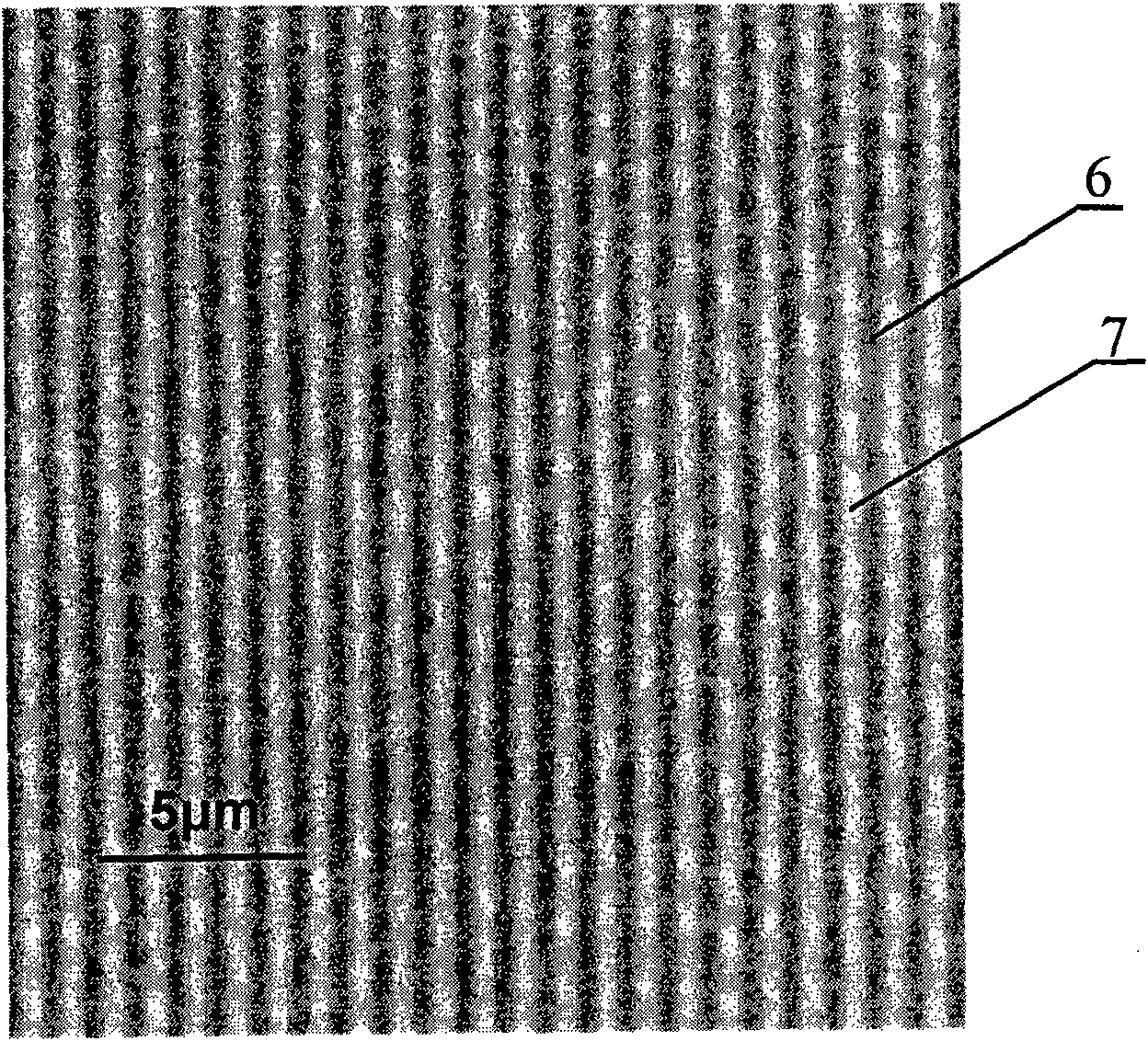

Solution method preparation for metal photon crystal

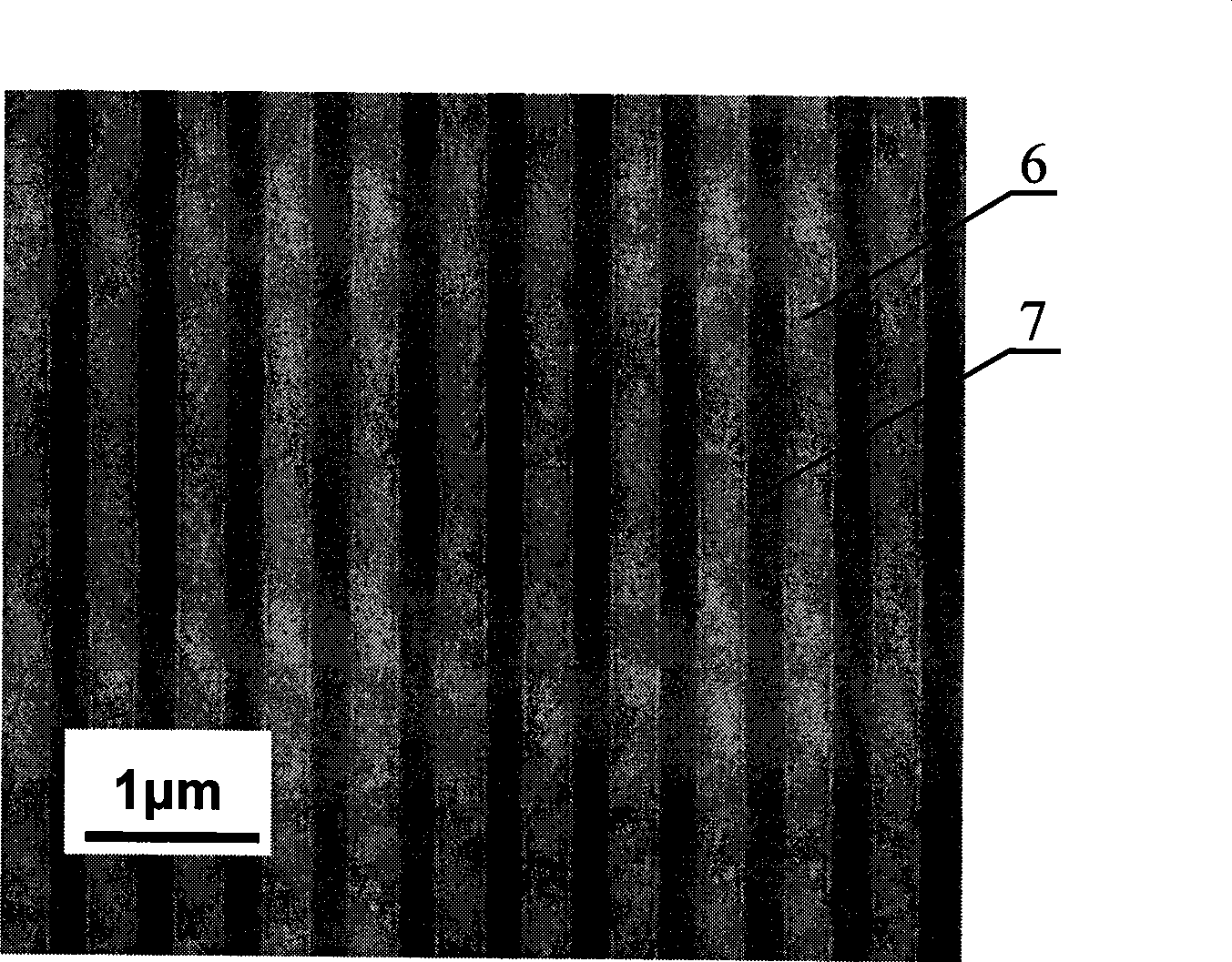

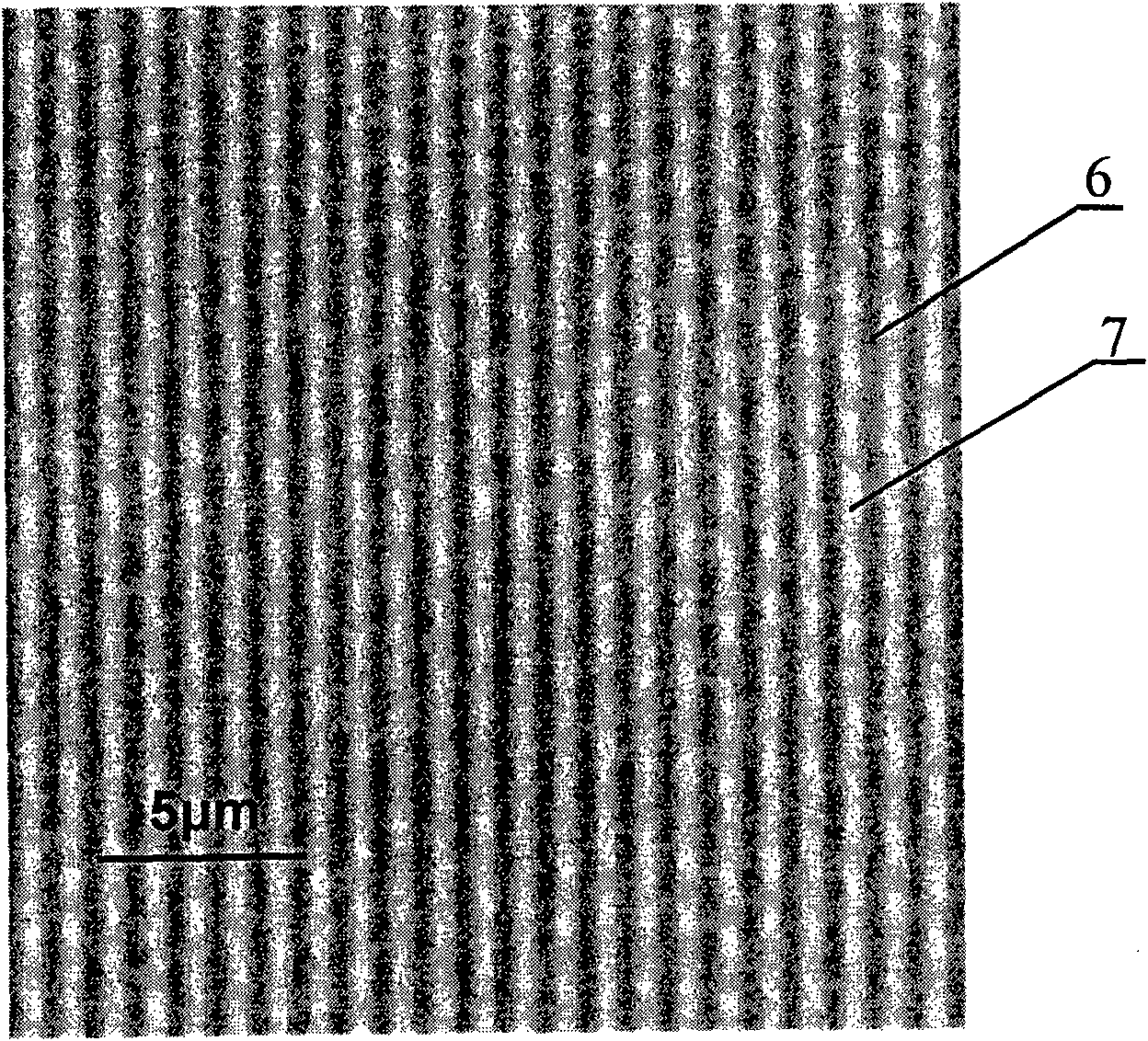

InactiveCN101487976ALow costGood repeatabilityPhotomechanical apparatusOptical light guidesResistGrating

The solution method for preparing metal photonic crystal belongs to the technical field of nano photoelectron materials and devices thereof. The existing method for preparing metal photonic crystal is faced with the problems such as high cost, low efficiency and small area of preparation, etc. In the invention, sequentially, optical resist is rotatably coated on a substrate; the interference photolithography is adopted to prepare one-dimensional or two-dimensional nano optical grating structures; metal nano particle sol is rotatably coated and goes through low temperature heat treatment, thus obtaining the metal photonic crystal. The invention has the advantages of low cost, high efficiency and preparation of the metal photonic crystal in a large acreage and the like.

Owner:BEIJING UNIV OF TECH

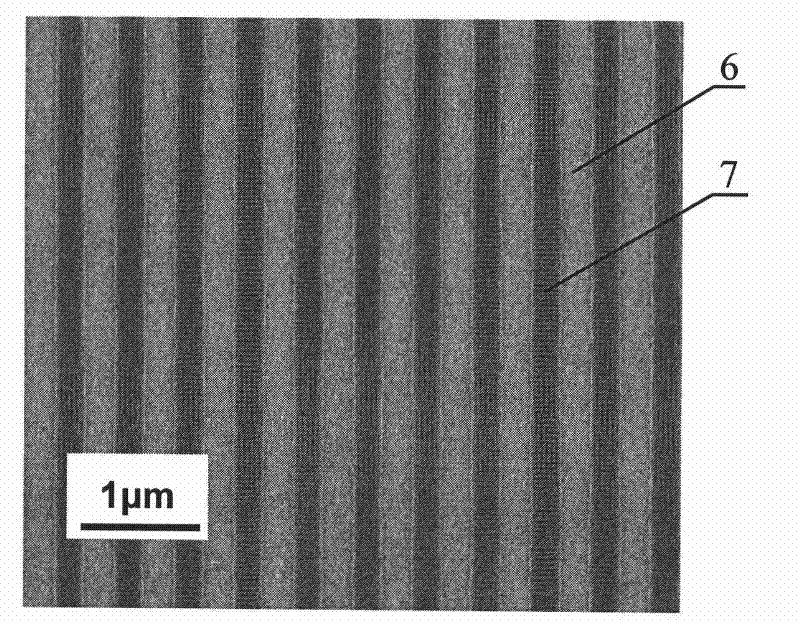

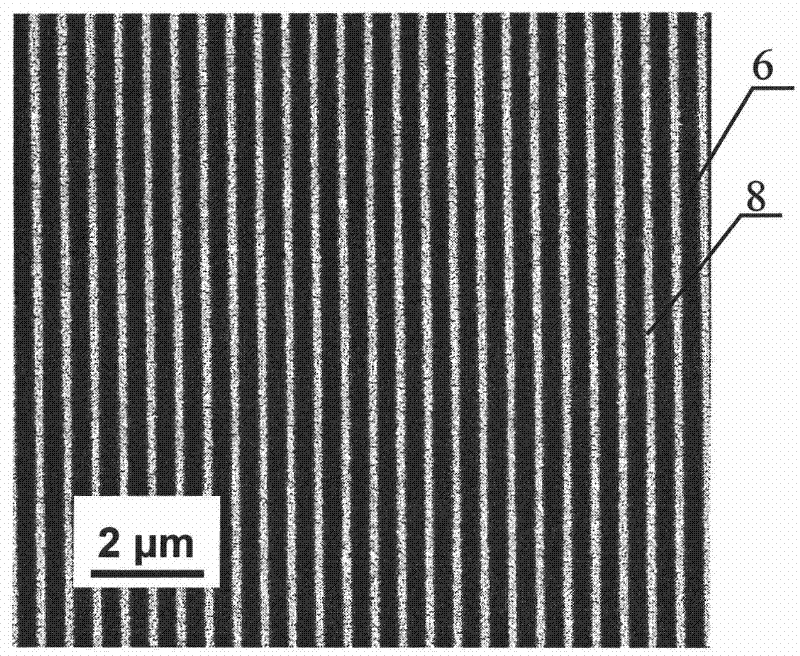

Method for directly writing metal micro-nano structure by ultraviolet laser interferometry etching

InactiveCN101973512ALow costGood repeatabilityNanostructure manufactureLaser beam welding apparatusChemical synthesisMicro nano

The invention discloses a method for directly writing a metal micro-nano structure by ultraviolet laser interferometry etching, and belongs to the technical field of nano ophoelectronic materials and devices. A metal nanoparticle colloid is synthesized chemically and then is directly acted on the surface of a metal film by a heat treatment process and an ultraviolet laser interferometry etching technique and thus, the novel technique for preparing a one-dimensional or two-dimensional photnic crystal is realized. The method has the advantages of low cost, high efficiency, capacity of preparinglarge-area metal photonic crystals, and the like.

Owner:BEIJING UNIV OF TECH

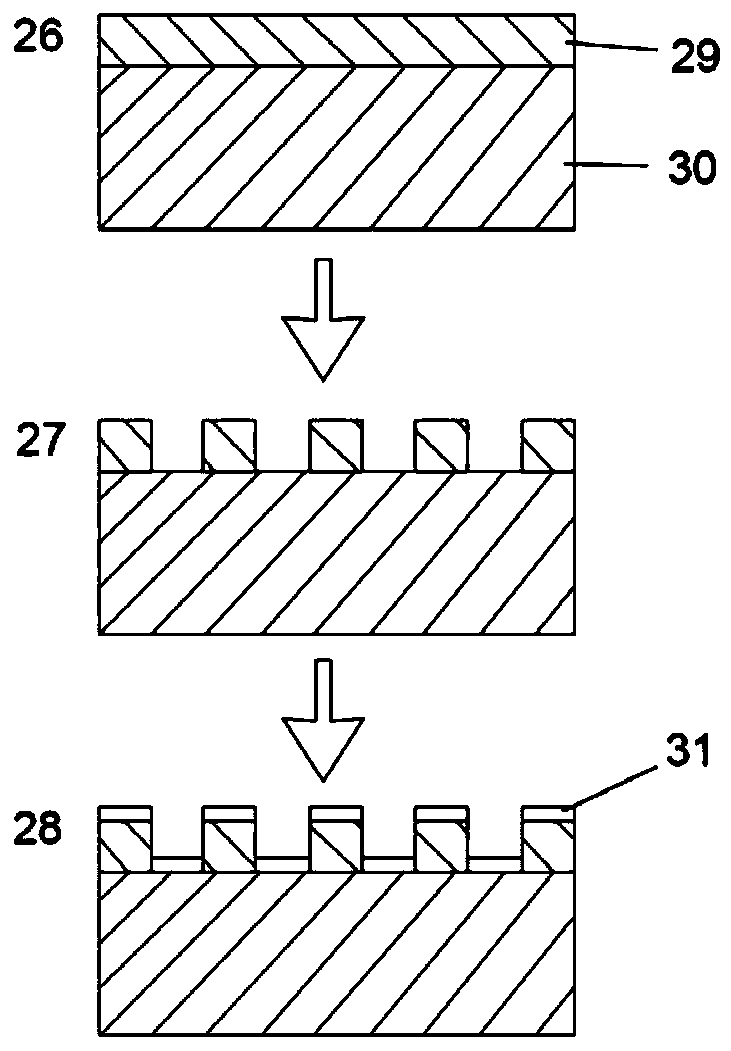

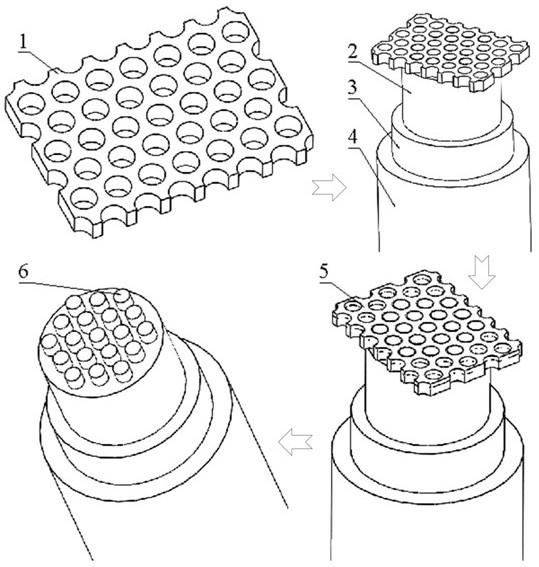

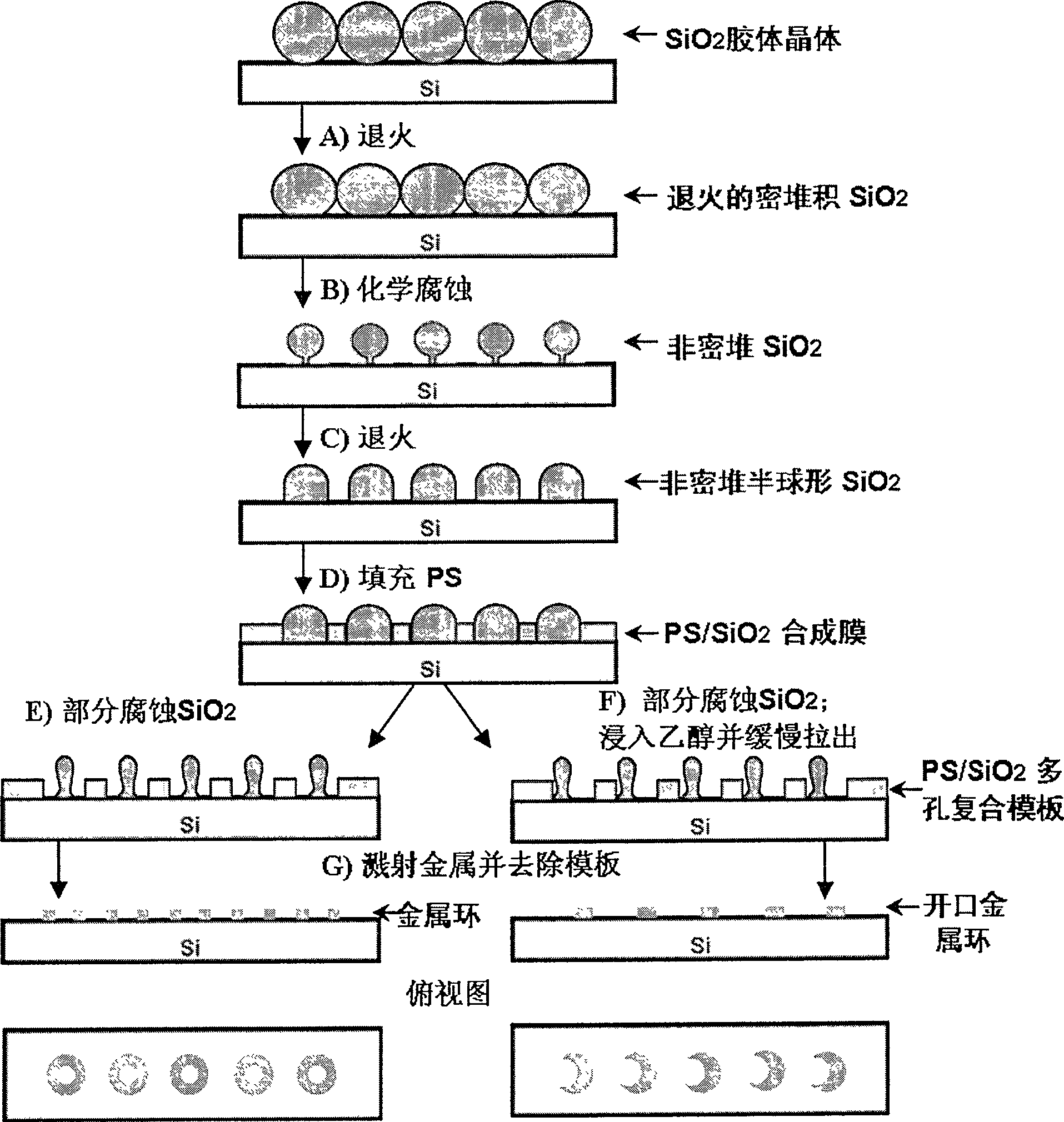

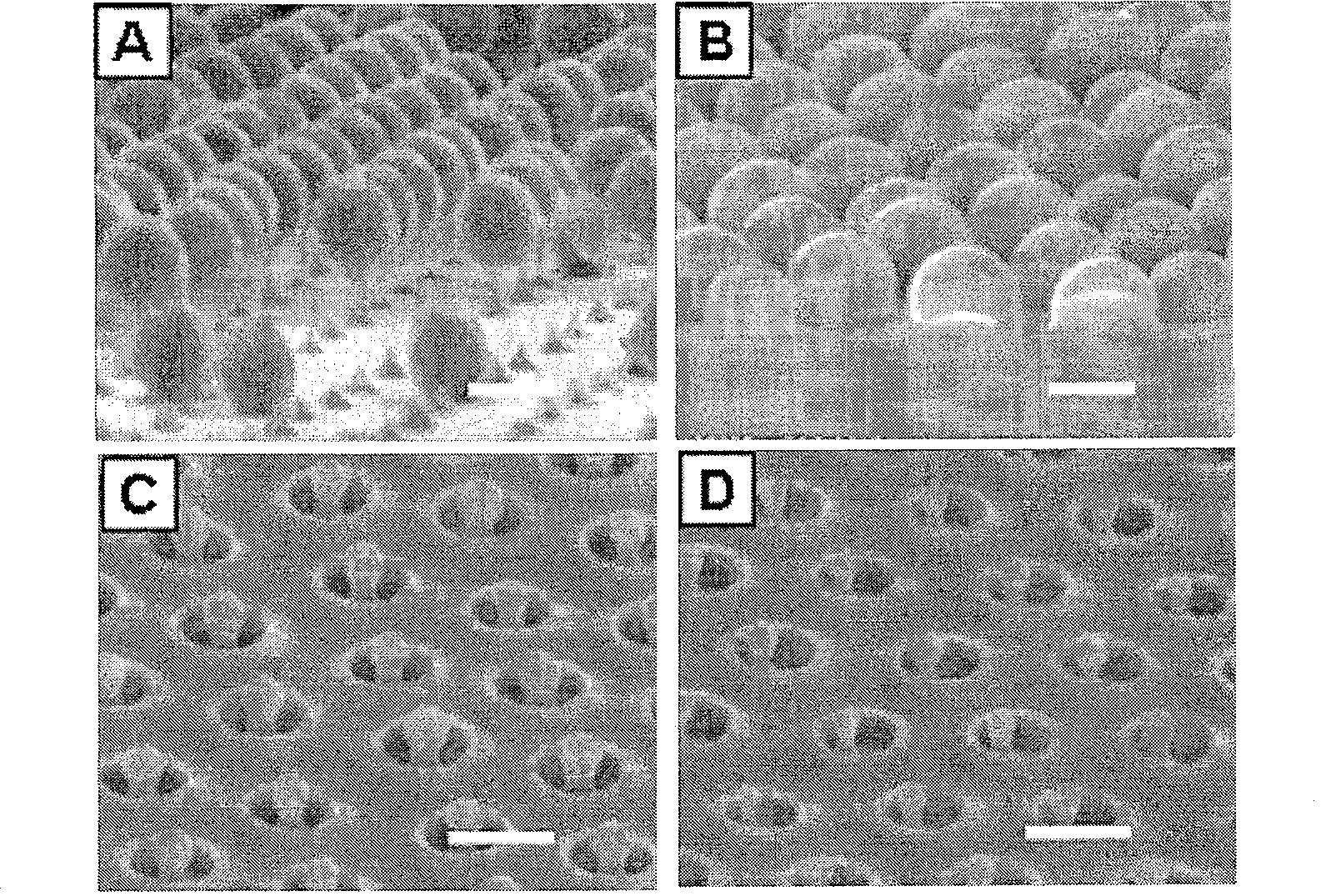

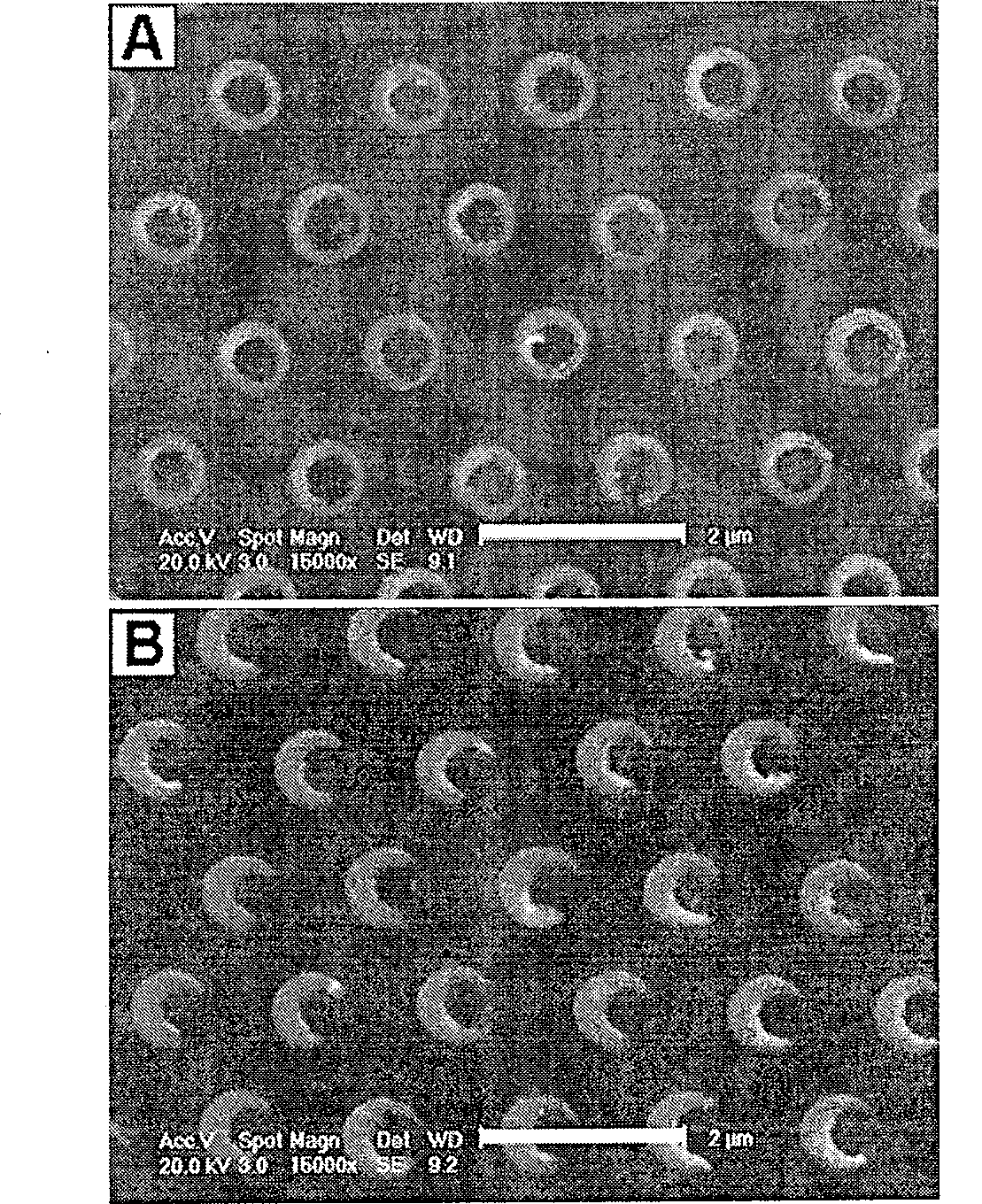

Method for preparing micron/submicron metal ring and open-mouth metal ring

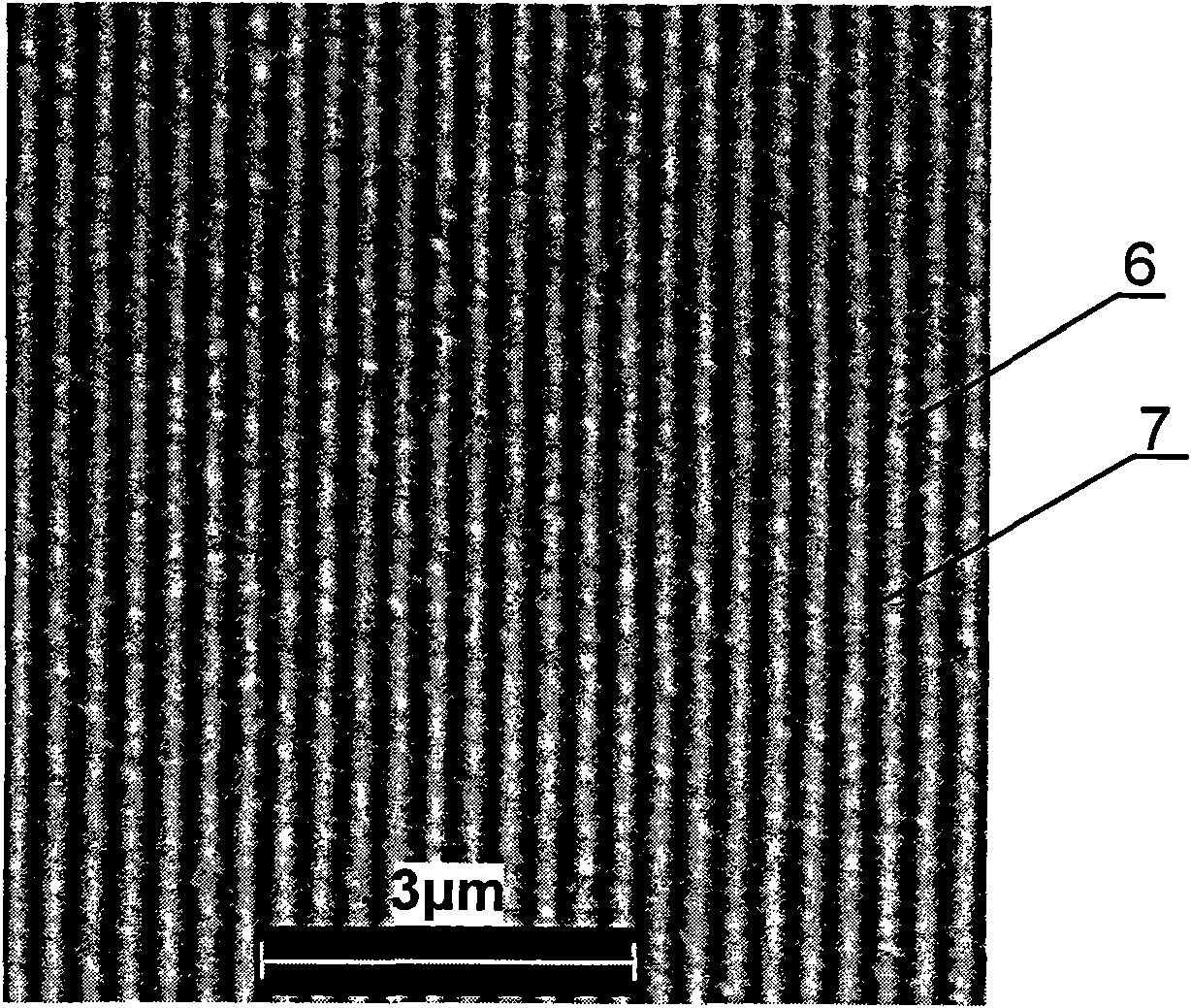

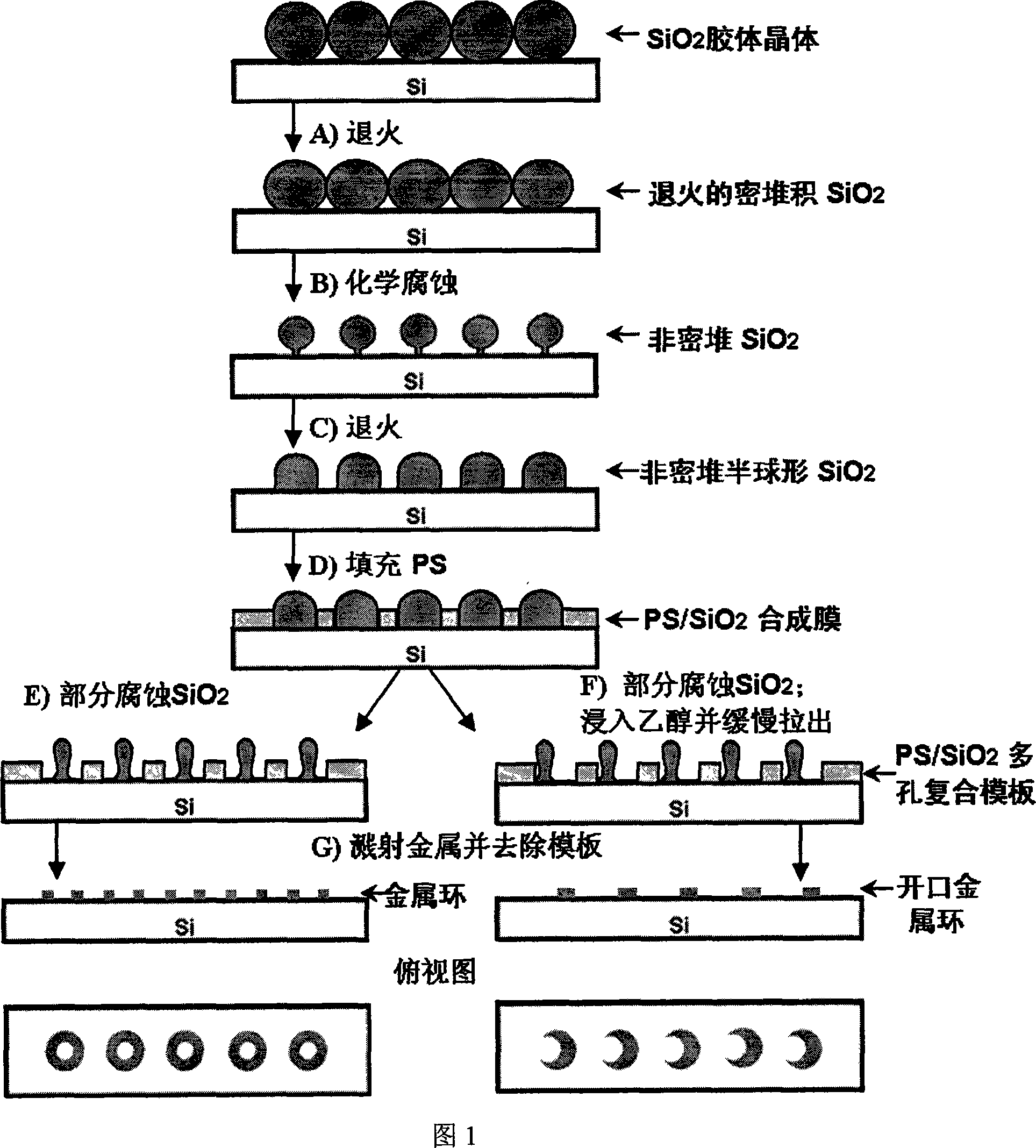

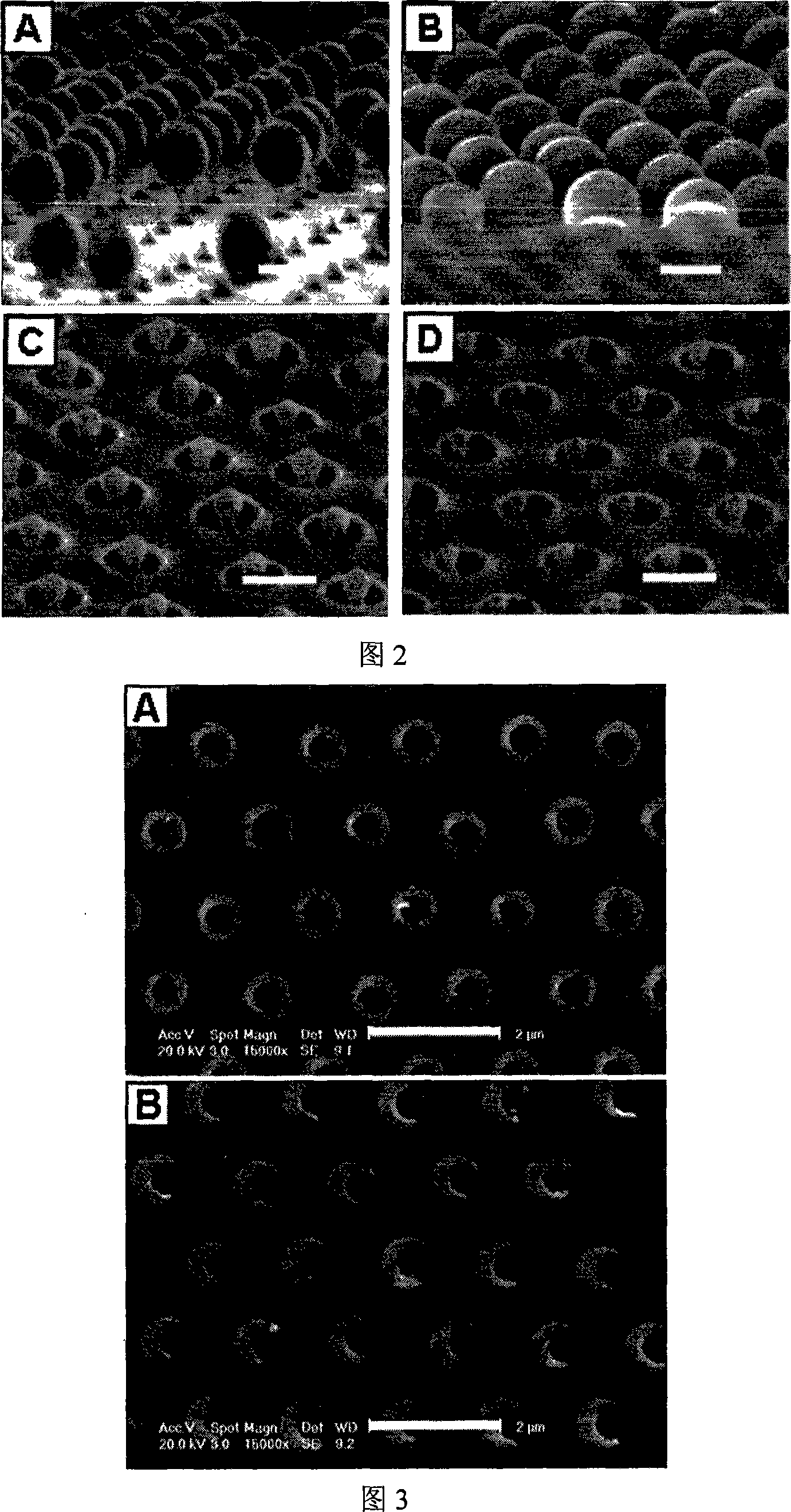

InactiveCN101070139AAdjustable thicknessCycle controllableSemi-permeable membranesFixed microstructural devicesHydrofluoric acidAlcohol

The invention discloses a preparing method of the micro / sub-micron ferrule and the open ferrule. It gets the two-dimensional colloid crystal by the self-organizing technology, then to anneal in high temperature, chemical corruption, the secondary anneal in high temperature to form the non close-packed two-dimensional structure; the polymer is filled into lattice space to form the compound film which is put in the hydrofluoric acid steam to go on the secondary corrosion and form the ring space; the surface of the compound module is spurted by metal, then to resolve the compound module to get the ferrule array structure. If the sample is dipped into the alcohol solution to make the ring space change the partiality ring space; then to spurt by metal and remove the compound module to get the open ferrule. The advance of the invention is: the structural parameter can be controlled; the inner and outer diameter of the ferrule and the open ring can be adjusted and the circle can be controlled; the single disperse character is good and the thickness is uniform; the interface is clear and the technology is simple.

Owner:NANJING UNIV

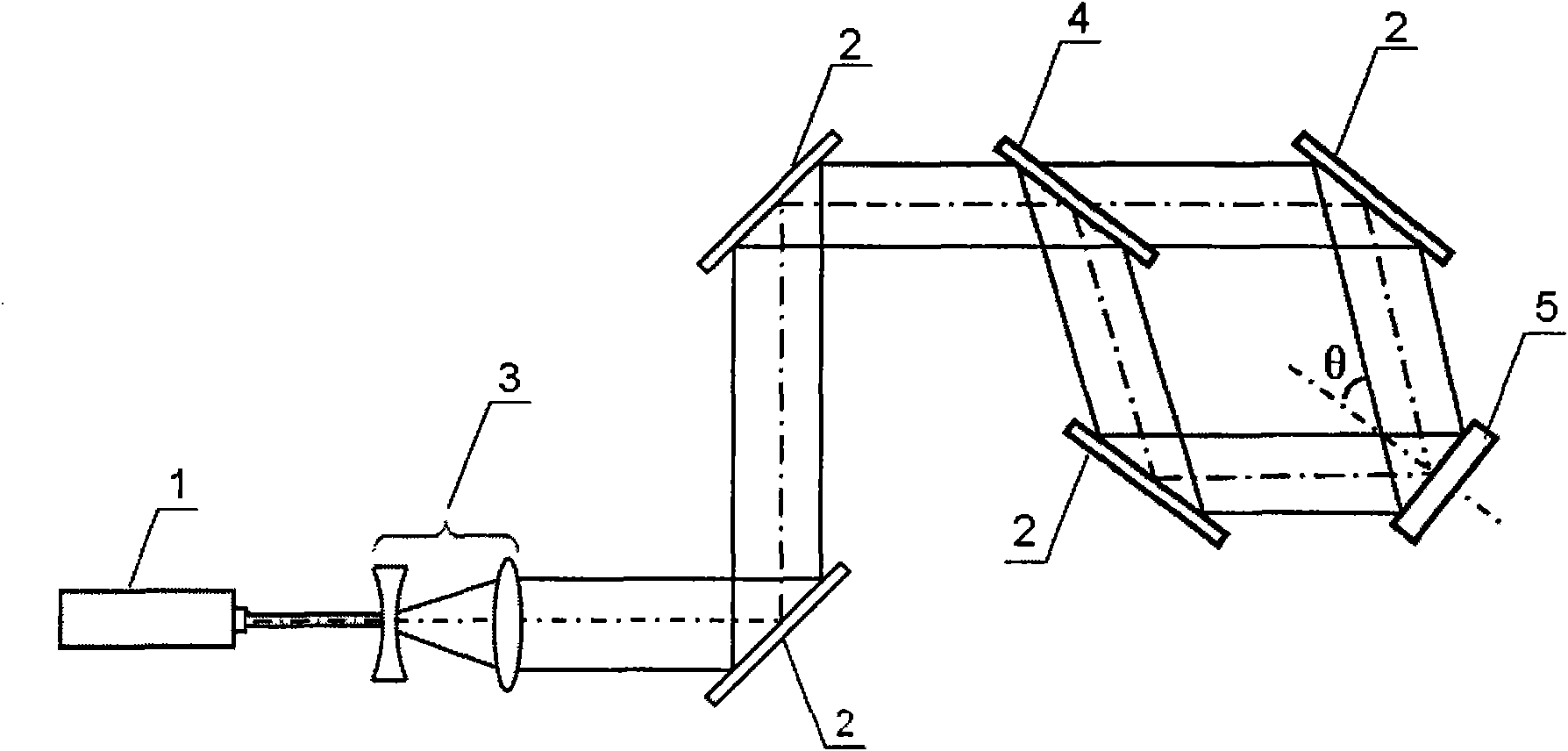

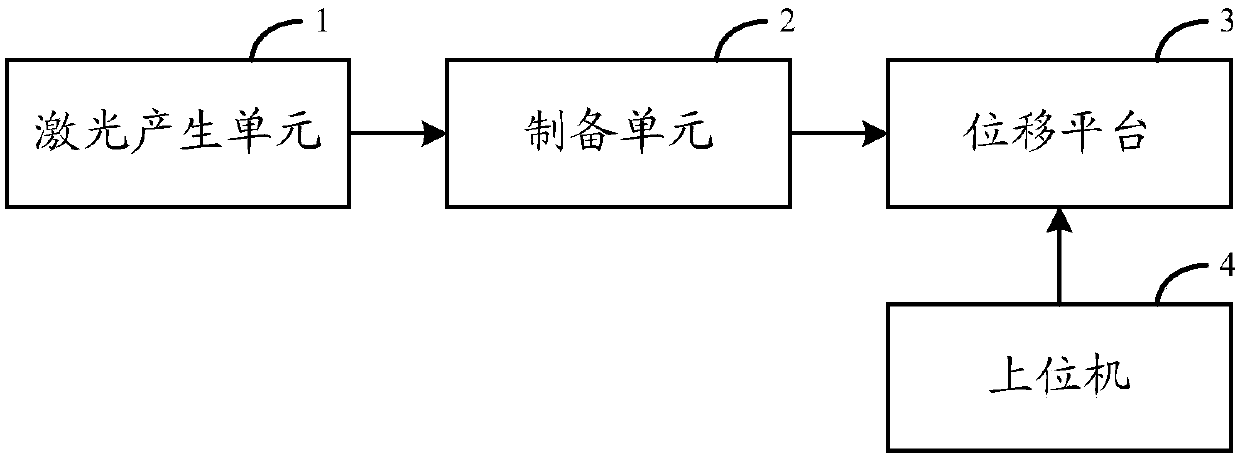

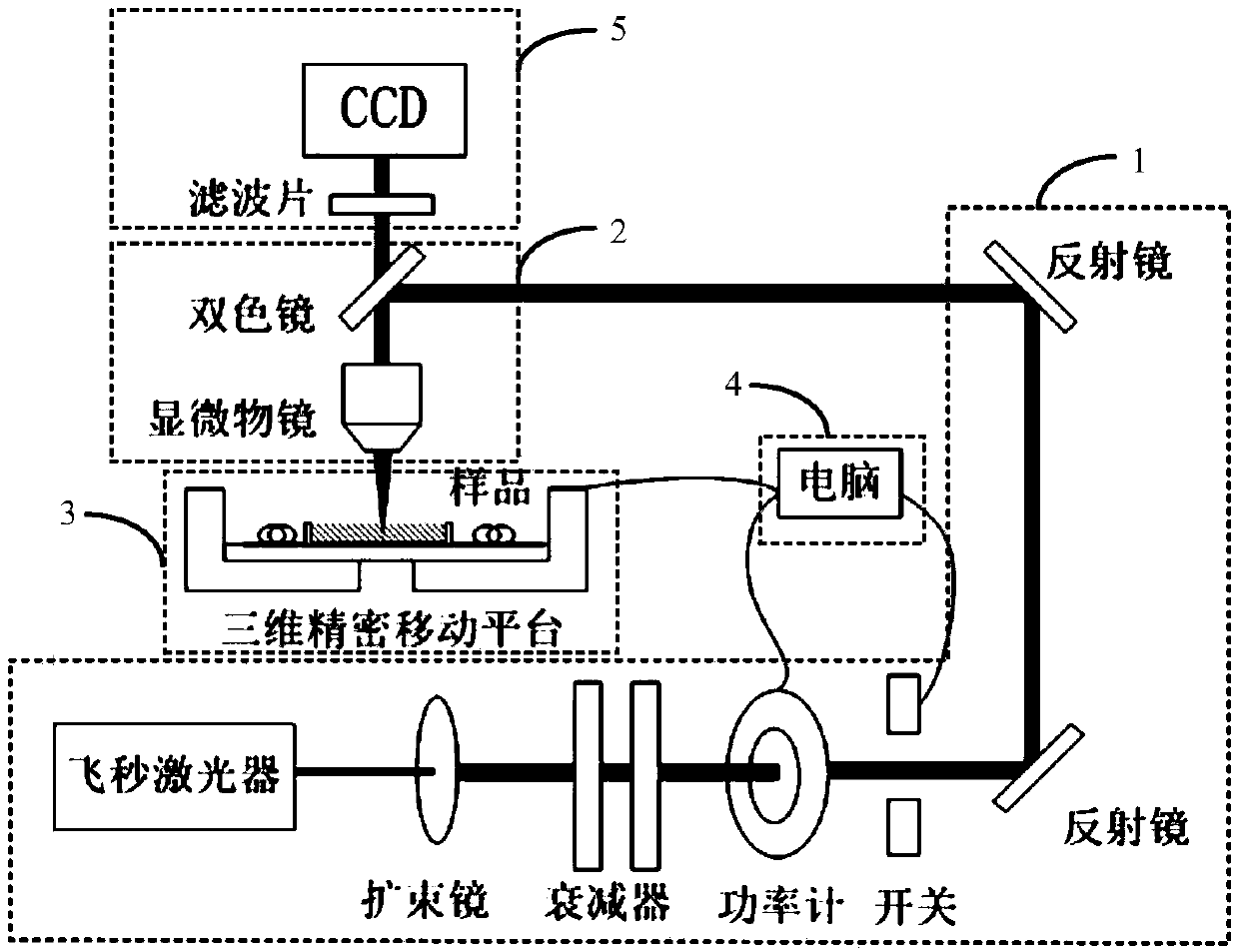

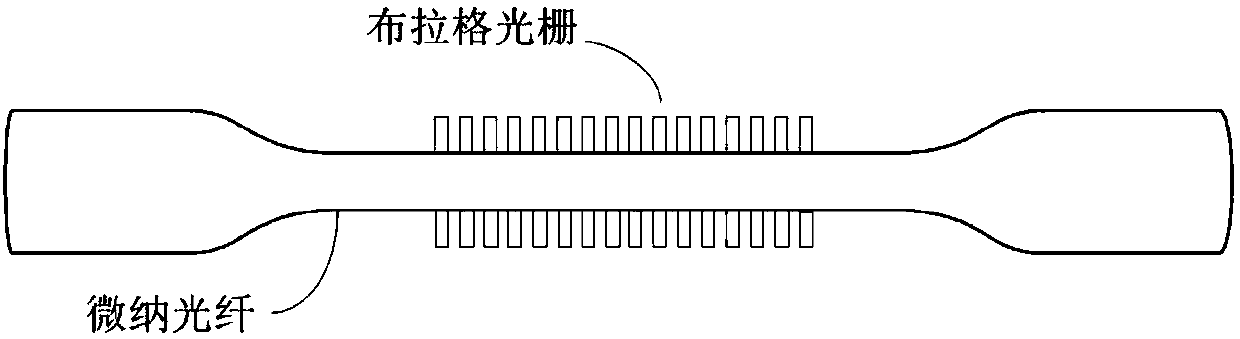

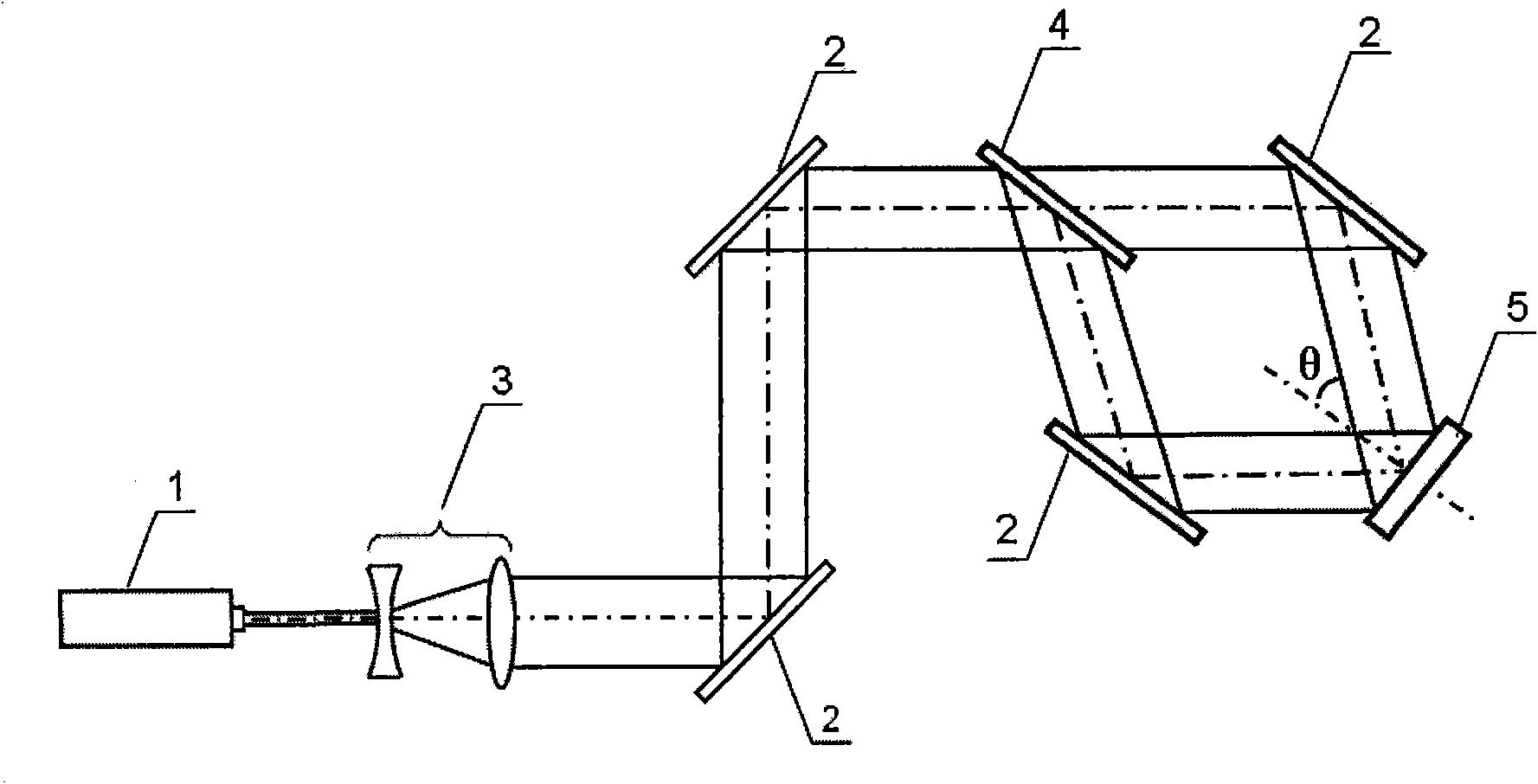

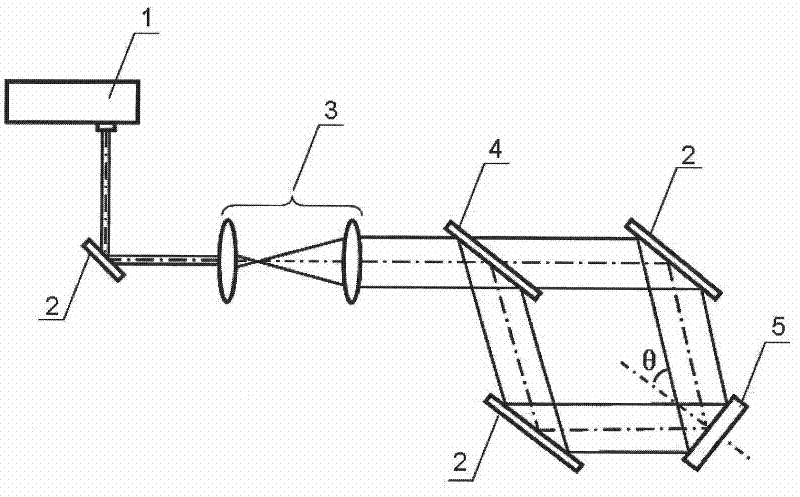

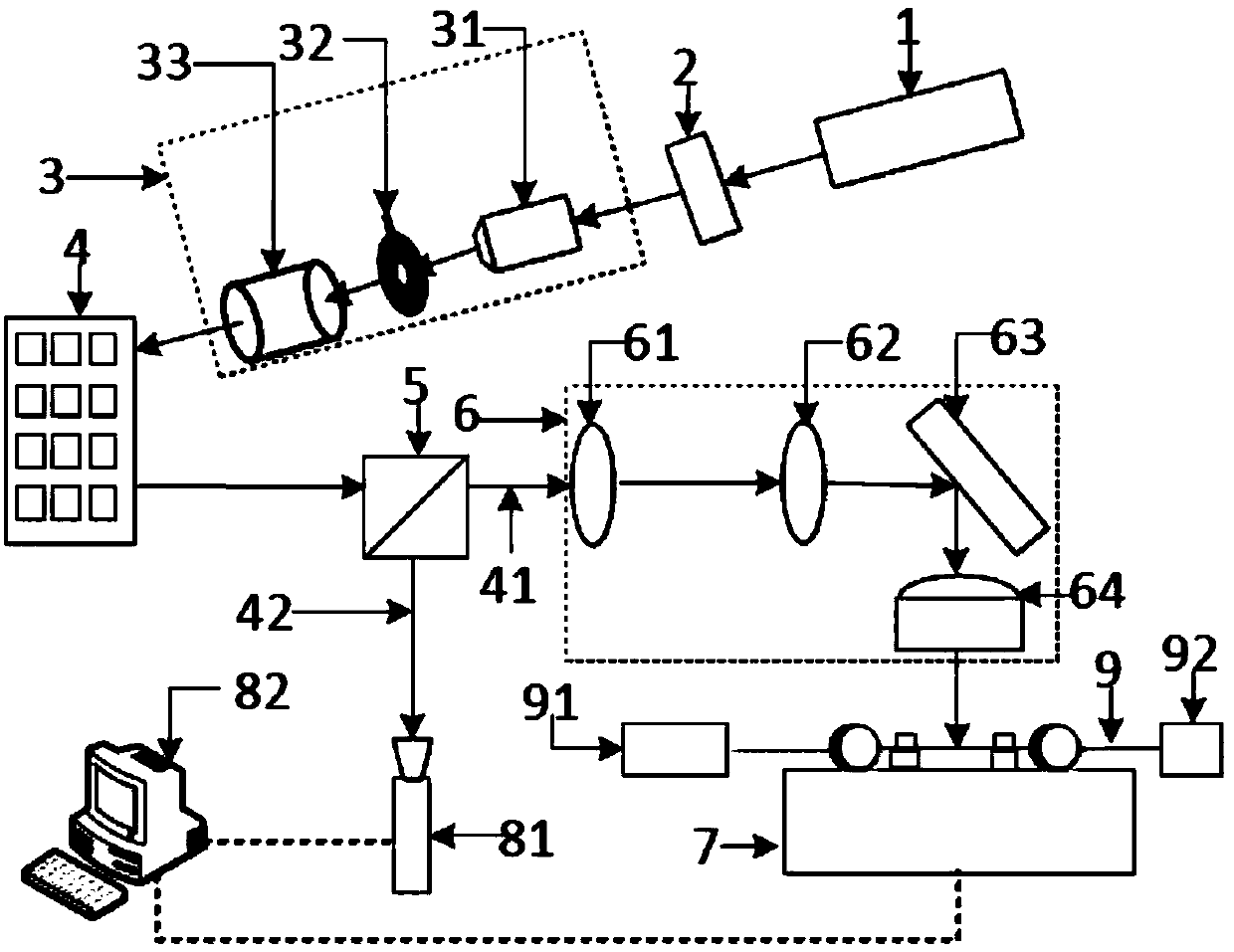

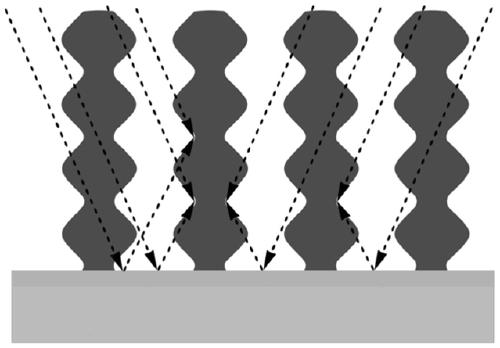

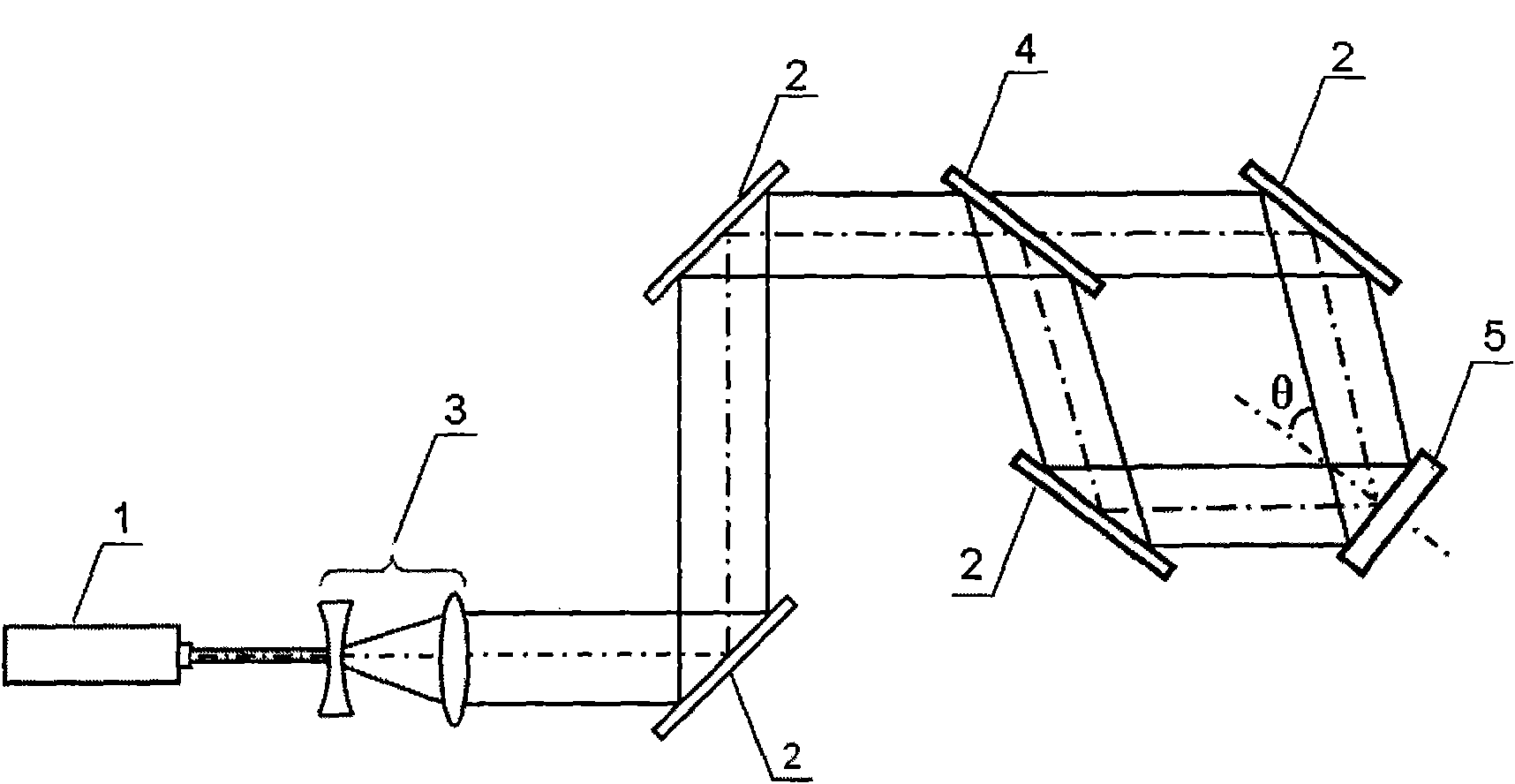

System and method for preparing micro-nano optical fiber Bragg gratings

ActiveCN107608022ACycle controllableImprove reflectivityCladded optical fibreOptical waveguide light guideMicro nanoGrating

The invention is applicable to the technical field of gratings, and provides a method and a system for preparing micro-nano optical fiber Bragg gratings. The system comprises a laser generating unit,a preparation unit, a displacement platform and an upper computer. Samples can be arranged on the displacement platform, and each sample is a micro-nano optical fiber coated with a layer of curing adhesive; the laser generating unit is used for generating femtosecond laser with preset power values and transmitting the femtosecond laser to the preparation unit; the preparation unit is used for focusing the femtosecond laser on the micro-nano optical fibers; the displacement platform can move under the control of the upper computer, so that radial scanning can be carried out by the femtosecond laser along the micro-nano optical fibers, and preliminarily arranged Bragg gratings can be cured on the micro-nano optical fibers. The method and the system in an embodiment of the invention have theadvantages that tedious grating sensitivity enhancement treatment procedures can be omitted when the micro-nano optical fiber Bragg gratings are prepared by the aid of the method and the system, grating periods can be controlled, and the micro-nano optical fiber Bragg gratings are high in reflectivity; the Bragg gratings prepared by the aid of the method and the system are cured on the surfaces ofthe micro-nano optical fibers and are extremely sensitive to external environments, and the system is low in cost.

Owner:SHENZHEN UNIV

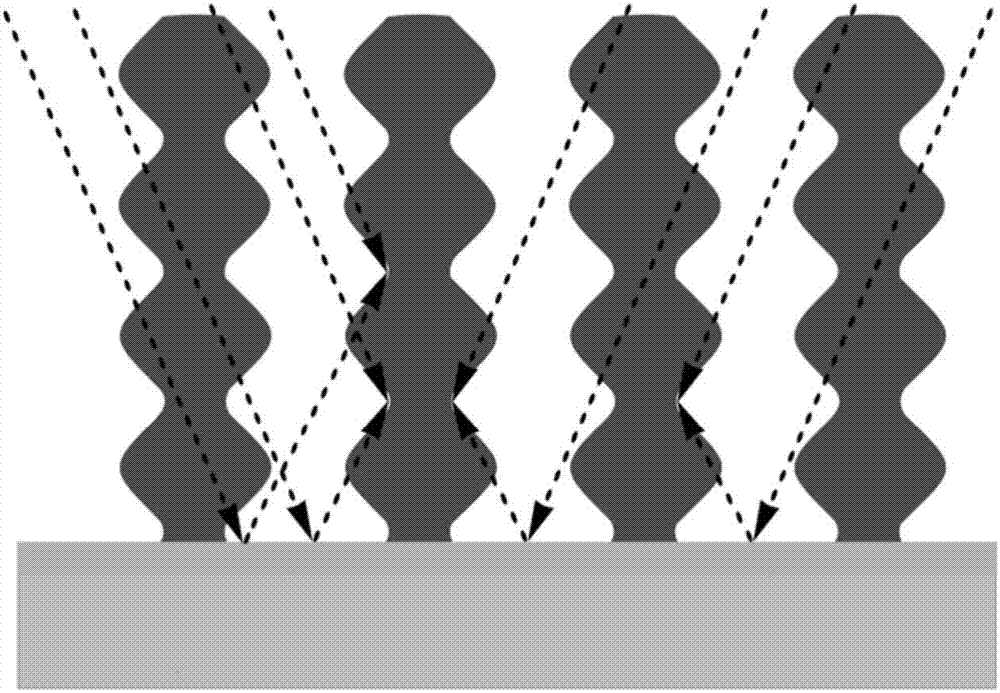

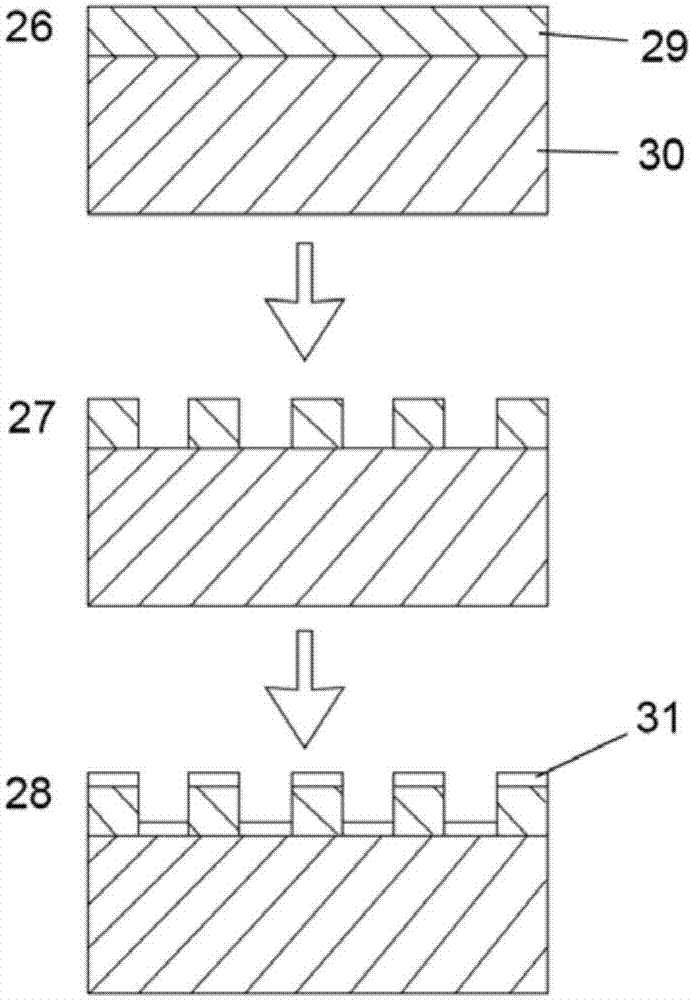

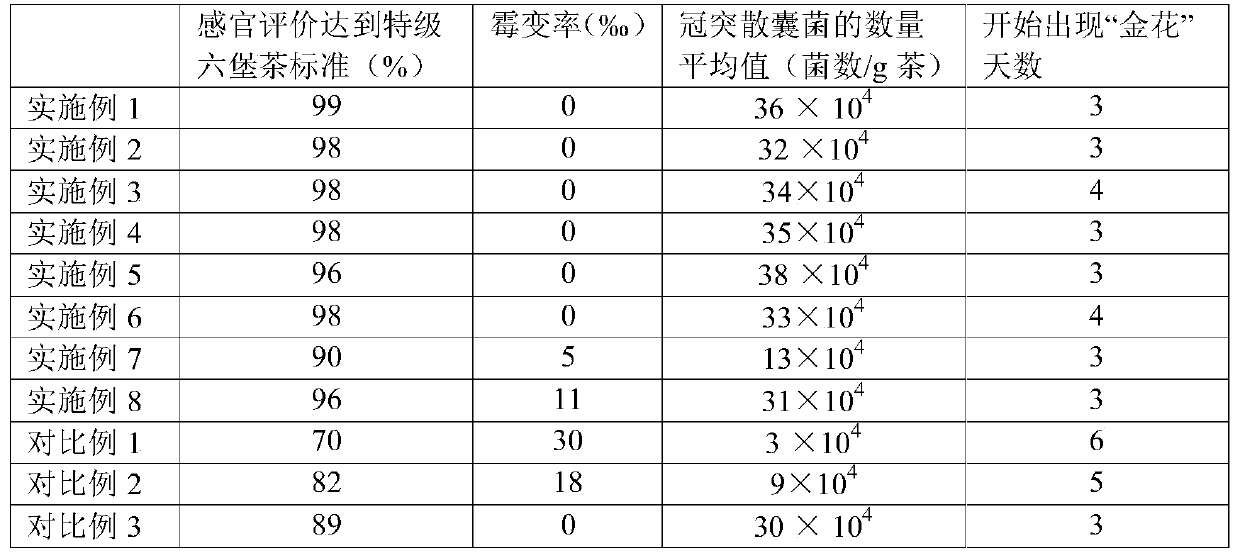

Gold nanoring stacked array substrate with surface enhanced Raman scattering and preparation method

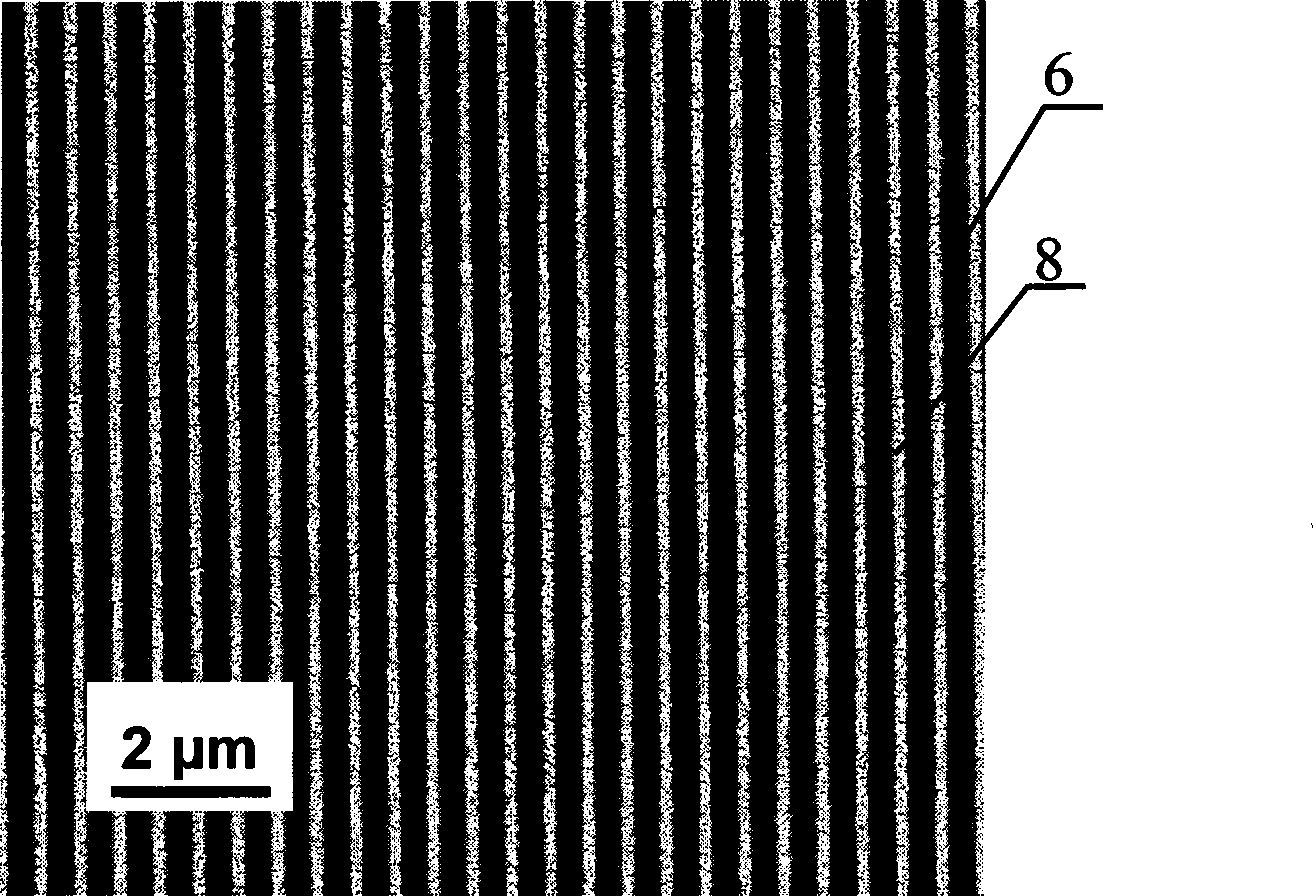

ActiveCN107966429ASimple processSimple technologyRaman scatteringPhotomechanical exposure apparatusLight beamLaser interference

The invention discloses a gold nanoring stacked array substrate with surface enhanced Raman scattering and a preparation method. The preparation method includes that standing wave effect in a photoetching process is utilized, in other words, surface reflection of an incident light substrate material interferes with incident light to form a specific stacked three-dimensional structure on photoresist, at the same time, multi-beam laser interference photoetching technology distributes and arranges the stacked three-dimensional structure according to a specified period, and a nano-thickness gold film is sputtered to form a gold nanoring stacked array. The structure has effect of surface enhanced Raman scattering and can be used for substrate materials for Raman scattering detection to effectively enhance Raman signals of detected substances.

Owner:CHANGCHUN UNIV OF SCI & TECH

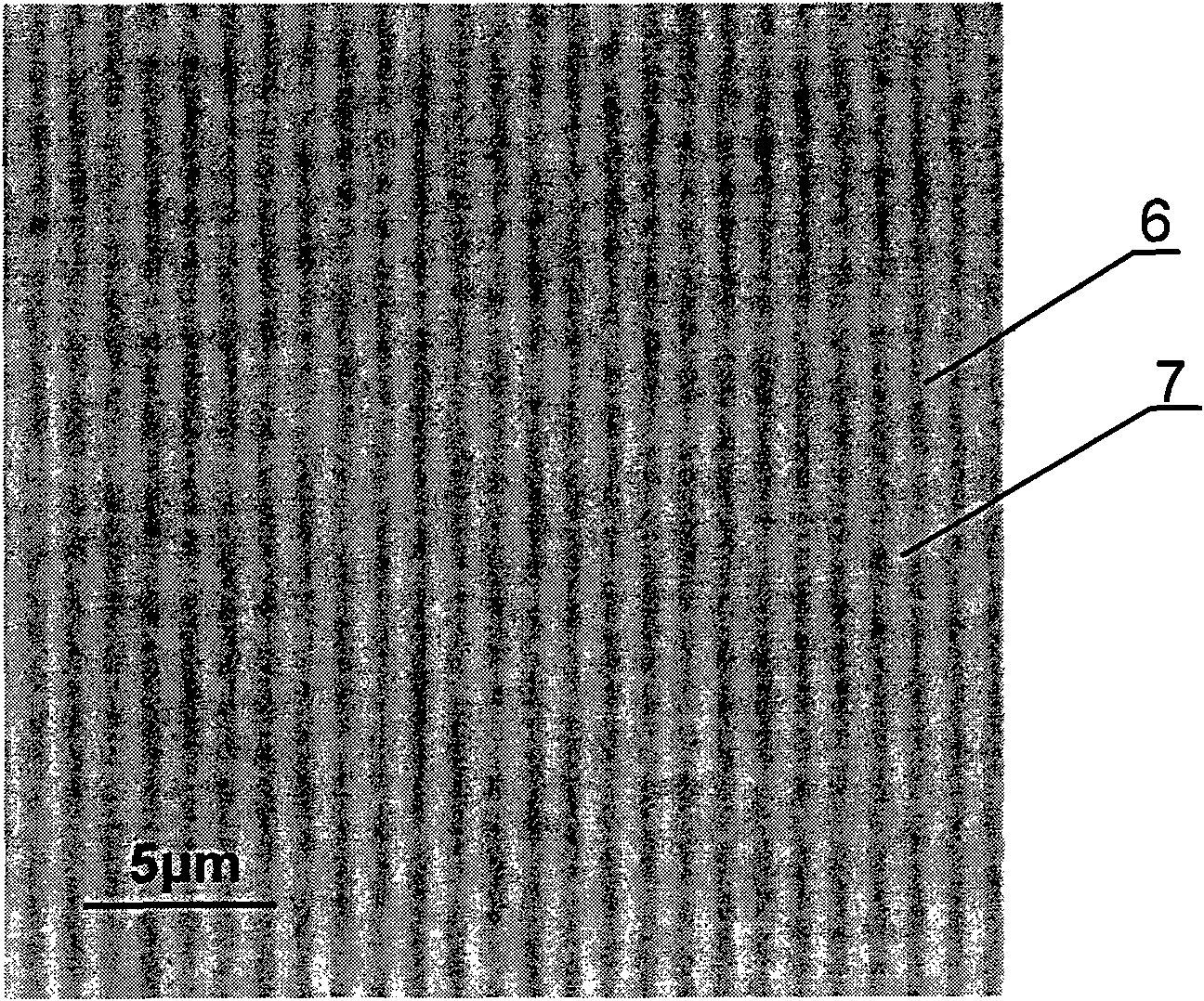

Method for directly writing organic semiconductor laser by ultraviolet laser interferometry etching

InactiveCN102649196ALow costGood repeatabilityLaser beam welding apparatusSemiconductor devicesEtchingFluorescence

The invention discloses a method for directly writing an organic semiconductor laser by ultraviolet laser interferometry etching and belongs to the technical field of nano photoelectronic materials and devices. The method comprises the steps as follows: (1), preparing fluorescent emission organic semiconductor material organic solution; (2), spin-coating the fluorescent emission organic semiconductor solution on a substrate to obtain an organic semiconductor membrane with uniform thickness of 50-500 nanometers; and (3), enabling strong ultraviolet laser interference patterns to act with the organic semiconductor membrane, so that the organic semiconductor membrane in an interference bright strip area is etched instantly and the unexposed area is left. The method has the advantages of low cost, good repeatability, high preparation efficiency and controllable cycle, and can be used for preparing large-area one-dimensional or two-dimensional organic semiconductor lasers.

Owner:BEIJING UNIV OF TECH

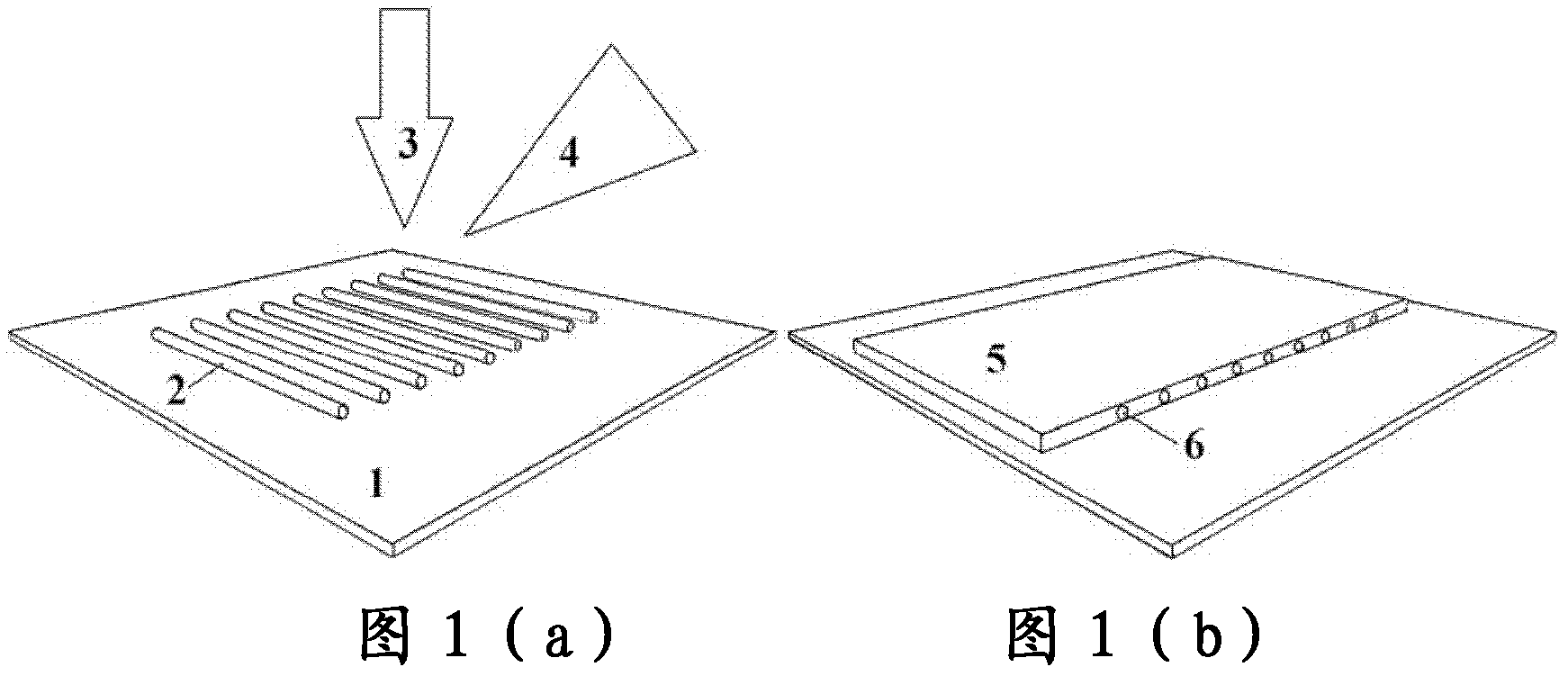

Preparation method for embedded micro-nano channel

InactiveCN102874743AImprove controllabilityHighly repeatableDecorative surface effectsChemical vapor deposition coatingMicro nanoEngineering

The invention discloses a method for preparing an embedded micro-nano channel, and relates to micro-nano processing technology. The method comprises the steps of (1) cleaning a substrate; (2) preparing a support sacrificial layer with the cross sectional dimensions on nanoscale; (3) putting and fixing the processed sample by the step (2) in a device; (4) observing graphics to find the position of the nanostructure of the support sacrificial layer; and (5) depositing a tungsten covering layer on the support sacrificial layer through an ion beam-assisted deposition technology. The preparation method is based on a phenomenon of disappearance of the nanostructure of the support sacrificial layer to prepare the embedded micro-nano channel after the tungsten covering layer is deposited by aid of the ion beam, is flexible in process, has high efficiency and good controllability, and is a manufacturing method for the micro-nano channels with any shape inside a material body.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Photonic crystal micro-nano structure direct-writing method based on metal nanoparticles

The invention discloses a photonic crystal micro-nano structure direct-writing method based on metal nanoparticles, which belongs to the technical field of nano optoelectronic materials and nano optoelectronic devices. By using a chemically compounded metal nanoparticle colloid, a new preparation technology of a one-dimensional or two-dimensional metal photonic crystal is realized by a UV pulse laser interference burning technology and a heat processing process. The method has the advantages of low cost, high efficiency, and the like, and can be used for preparing metal photonic crystals in a large area.

Owner:BEIJING UNIV OF TECH

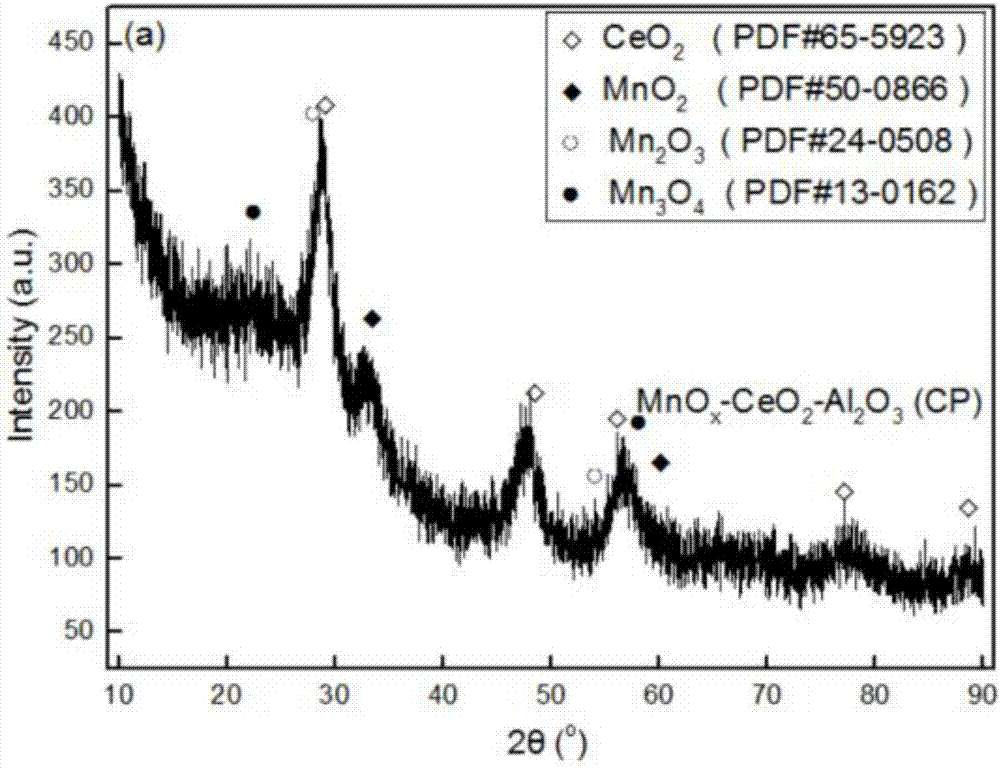

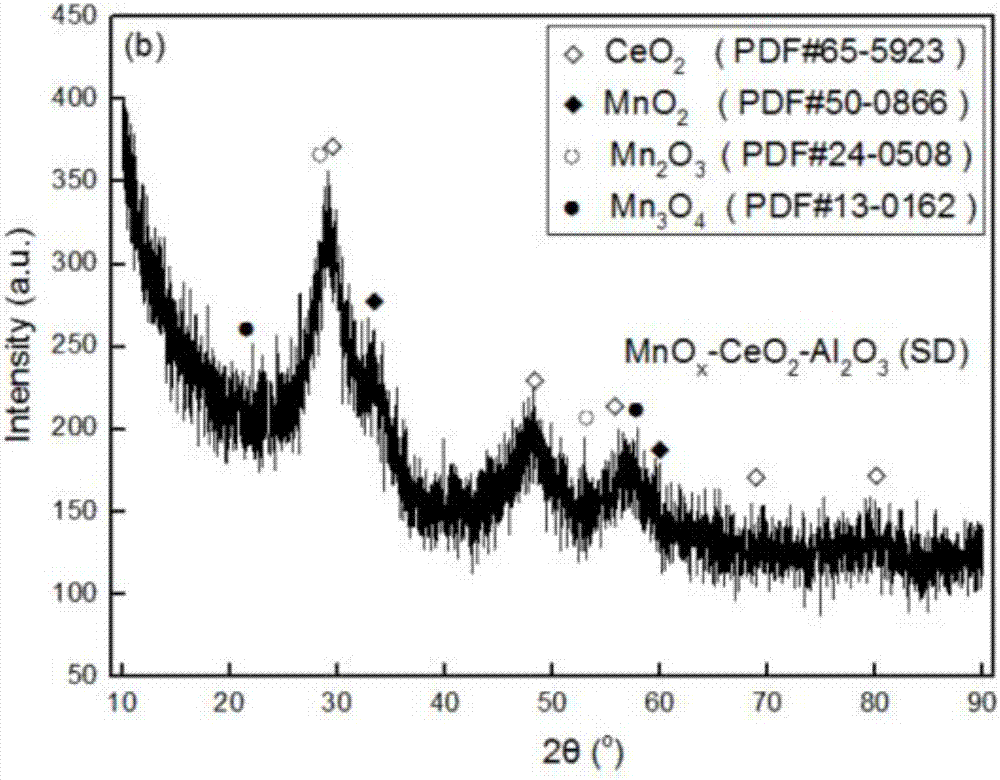

Spherical denitration catalyst and preparation method thereof

ActiveCN107970918AShort manufacturing timeRetain spherical structureGas treatmentHeterogenous catalyst chemical elementsSalt solutionLoad capacity

The invention discloses a spherical denitration catalyst and a preparation method thereof, and belongs to the field of catalysts. The preparation method of the spherical denitration catalyst comprisesthe following steps: (1) preparing a precursor salt solution; (2) preparing a precursor; and (3) drying the precursor, and then calcining the dried precursor to obtain a spherical denitration catalyst powder. The invention also discloses the spherical denitration catalyst. According to the spherical denitration catalyst and the preparation method thereof, the preparation cycle is short, and the operation is simple, thus the preparation method can be used for large-batch continuous production; and the prepared spherical denitration catalyst powder has a high low-temperature activity, and has excellent fluidity and dispersibility, so that in overall catalyst coating, increase of coating thickness and load capacity is facilitated.

Owner:浙江天麟环境工程有限公司

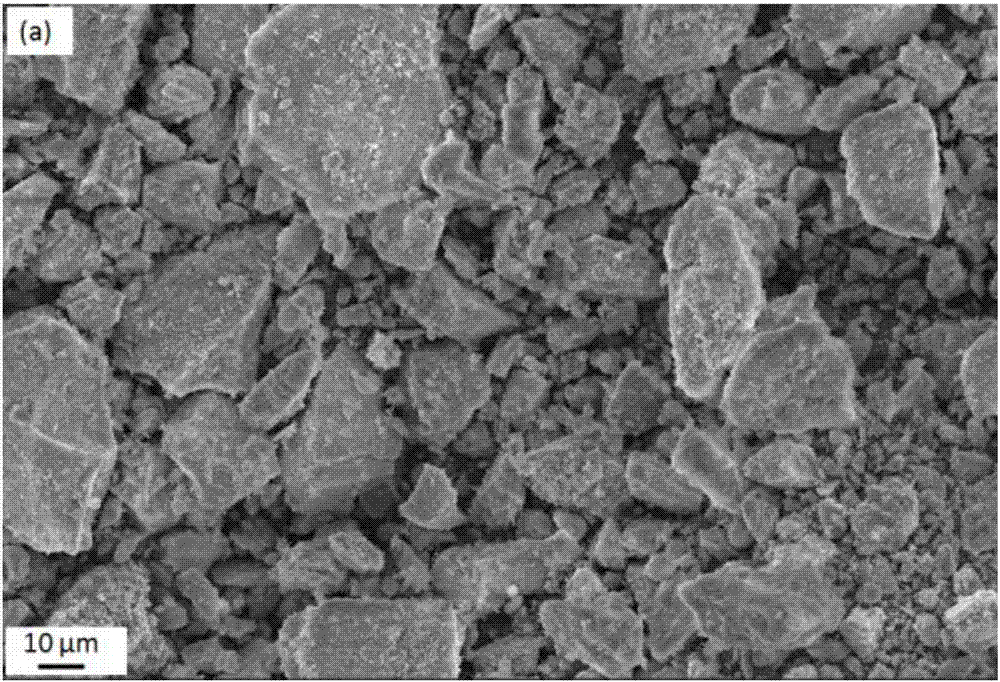

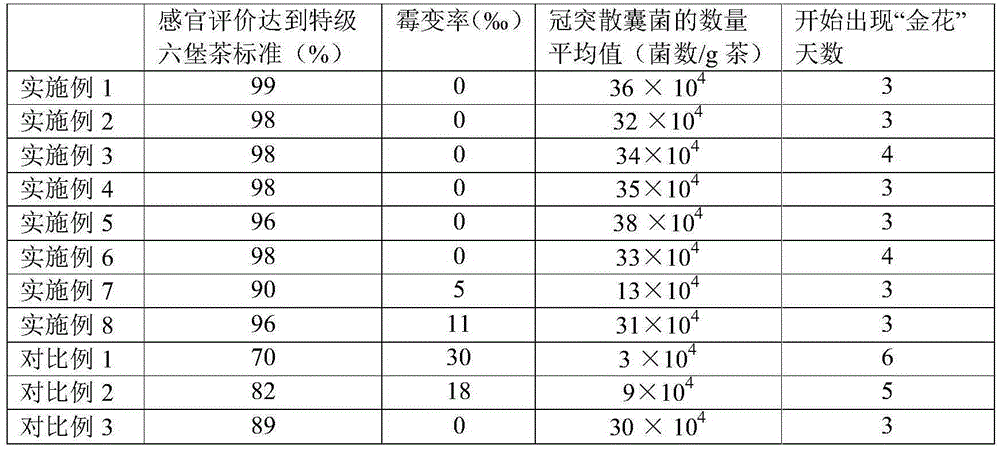

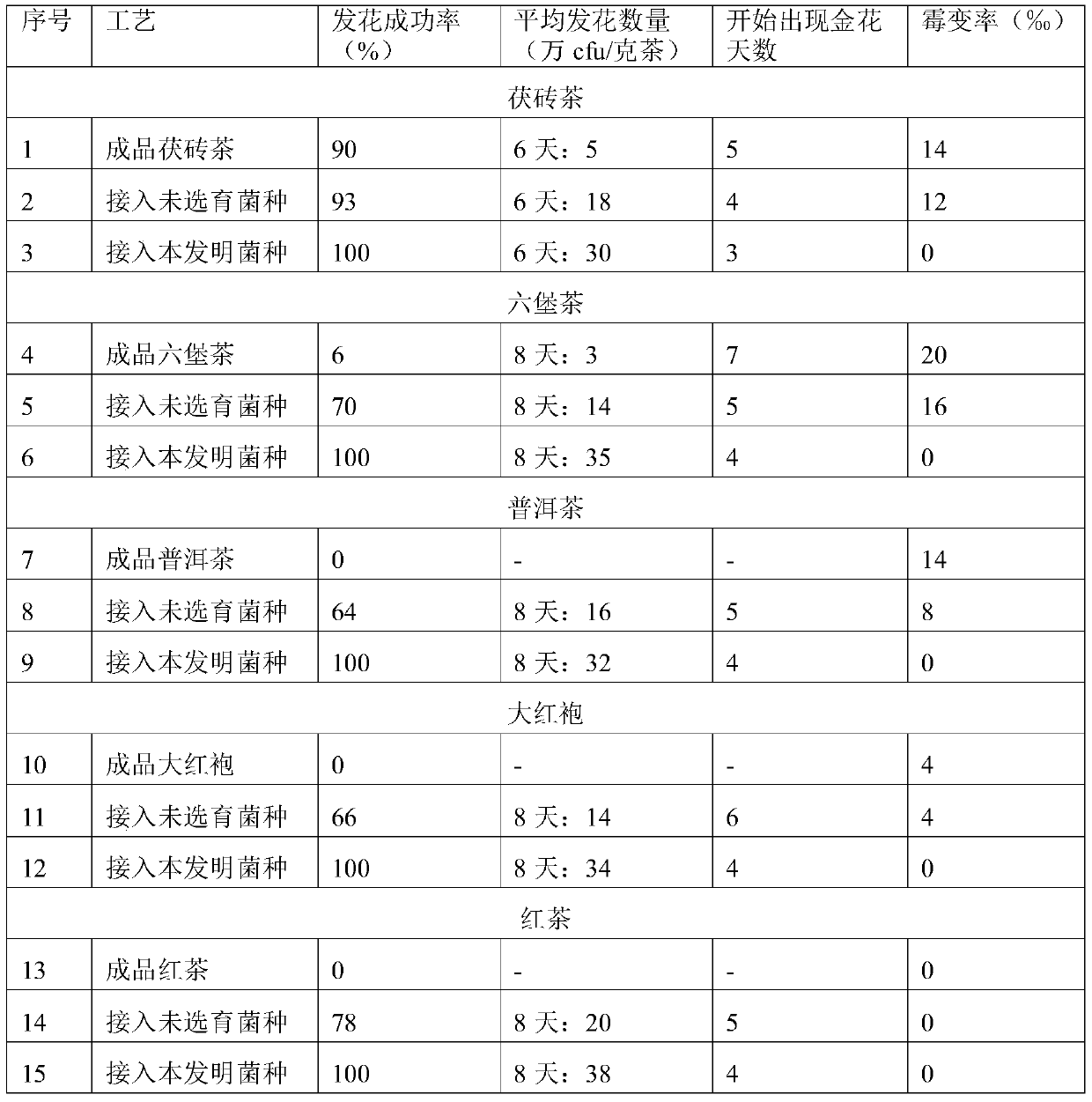

Eurotium cristatum Liupao tea standardization production process

ActiveCN105394233AThe number of blooms has steadily increasedCycle controllablePre-extraction tea treatmentMicroorganismFermentation

The present invention belongs to the technical field of microorganisms and food biology, and particularly relates to a Eurotium cristatum Liupao tea standardization production process, which comprises a Eurotium cristatum fermentation step, wherein the key step of the Eurotium cristatum fermentation step is carrying out single strain fermentation on Eurotium cristatum having a preservation number of CGMCC NO.11040. According to the present invention, the prepared Zhongchajiaocang Liupao tea product can achieve the stable Eurotium cristatum fermentation so as to achieve the controlled number of the Eurotium cristatum in the Liupao tea product, the quality is stable, and the feature is distinctive.

Owner:中国土产畜产进出口有限责任公司

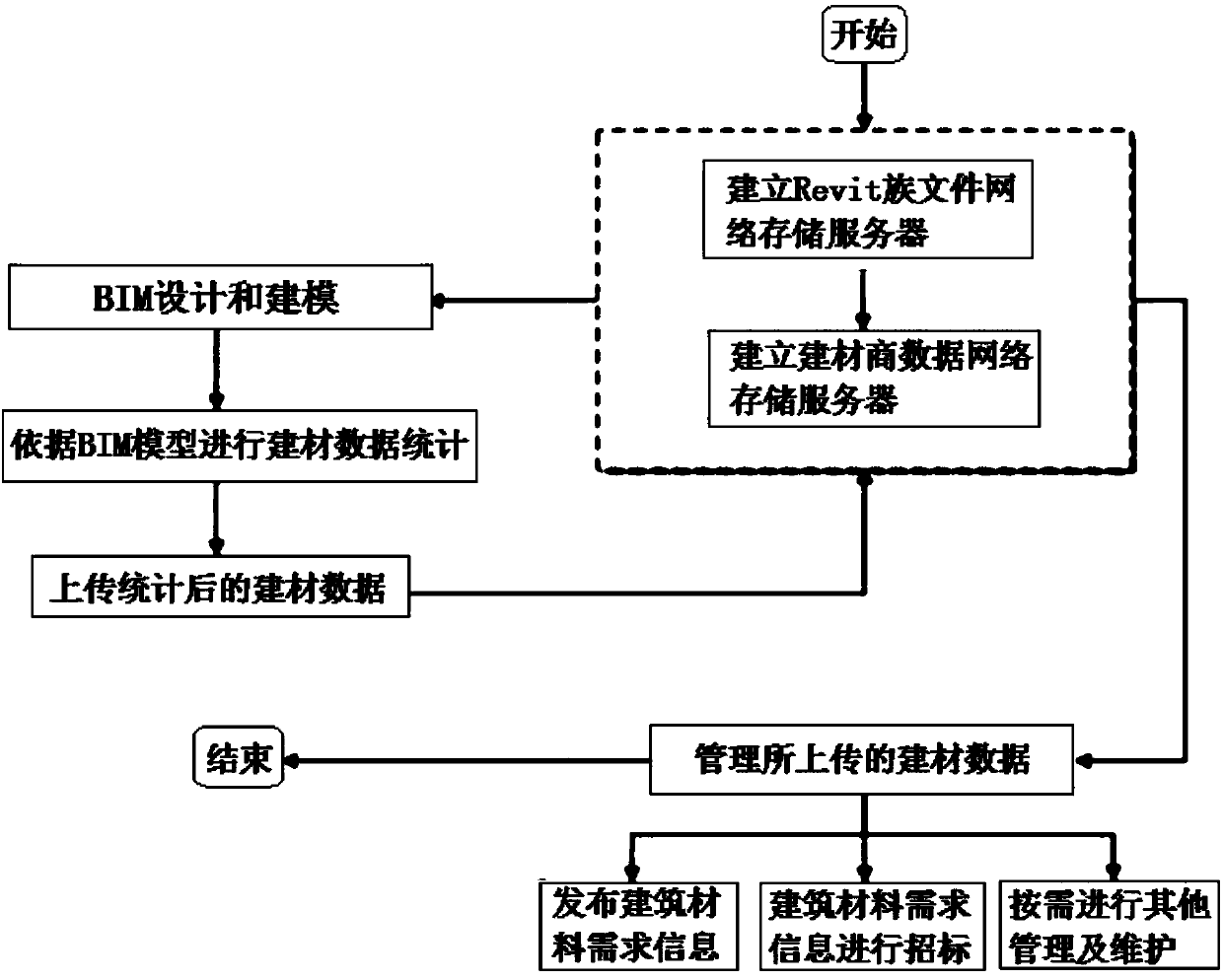

BIM-based building material business and building material information uploading system

InactiveCN108052726ASimplify purchasing difficulty and processLow costGeometric CADBuying/selling/leasing transactionsBusiness dataBuilding material

The invention discloses a BIM-based building material business and building material information uploading system. The system comprises a Revit-based BIM and a building material business data online statistics and uploading scheme. Through the technical scheme, after Revit modeling is finished, Revit family file data and corresponding building material business data are subjected to statistics from the BIM and uploaded to outside, so that project material purchase demands are directly formed, the goal that the BIM is equivalent to a purchase list is achieved, and the purchase problem of materials required for a project is effectively solved.

Owner:云南材材通信息技术有限公司

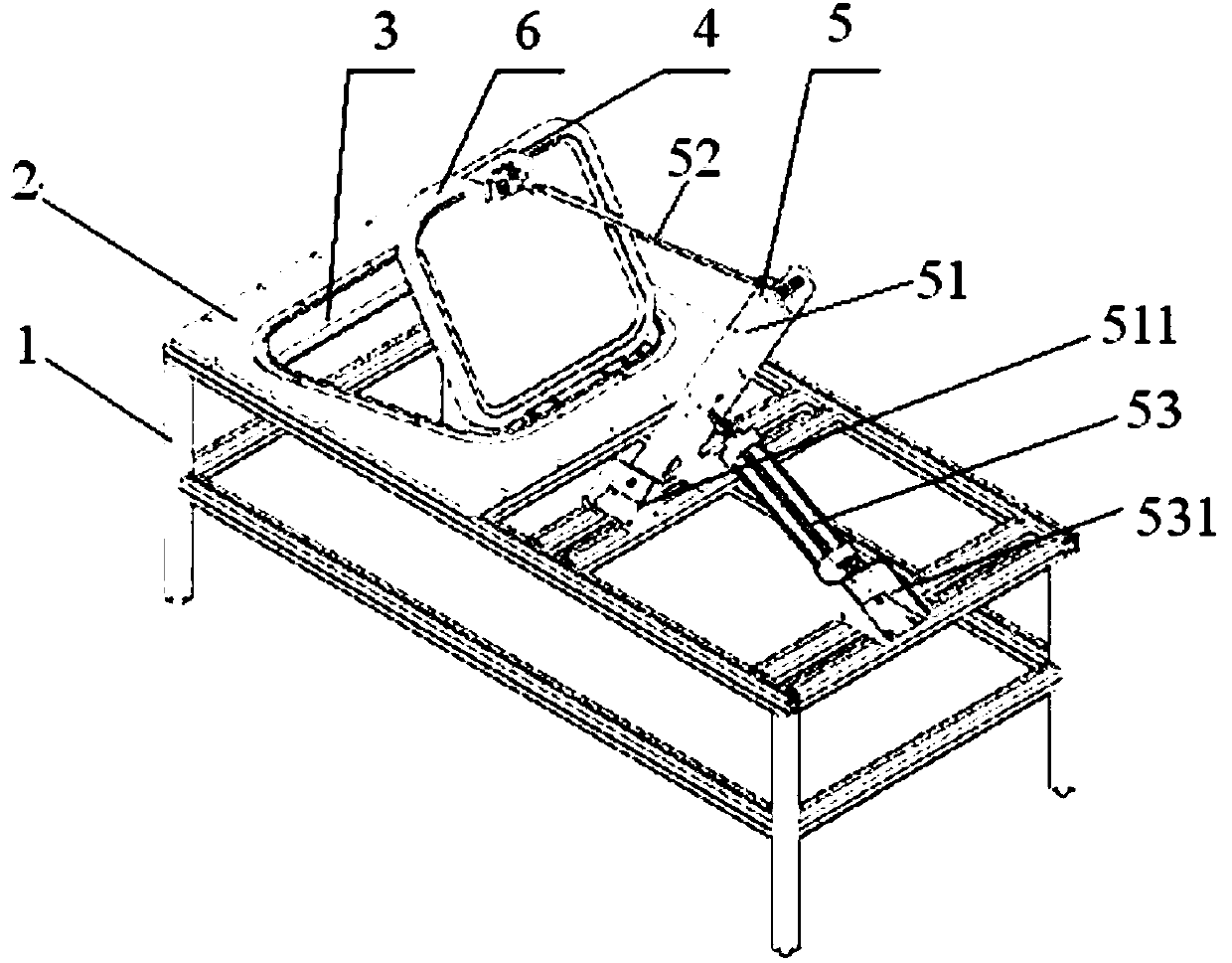

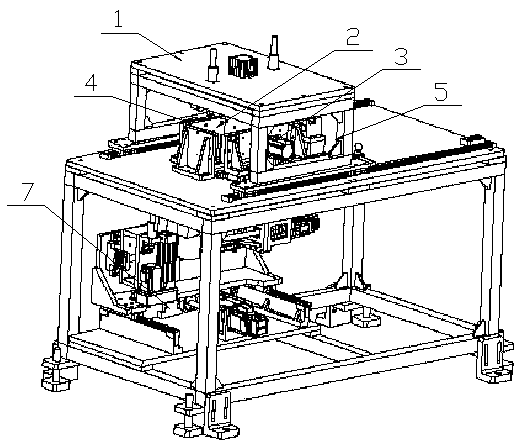

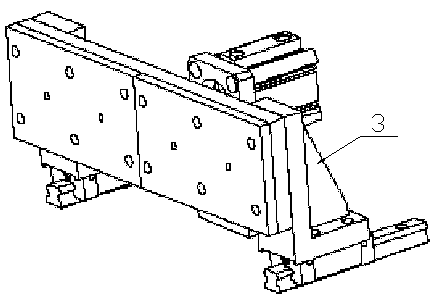

Locomotive side window durability testing device

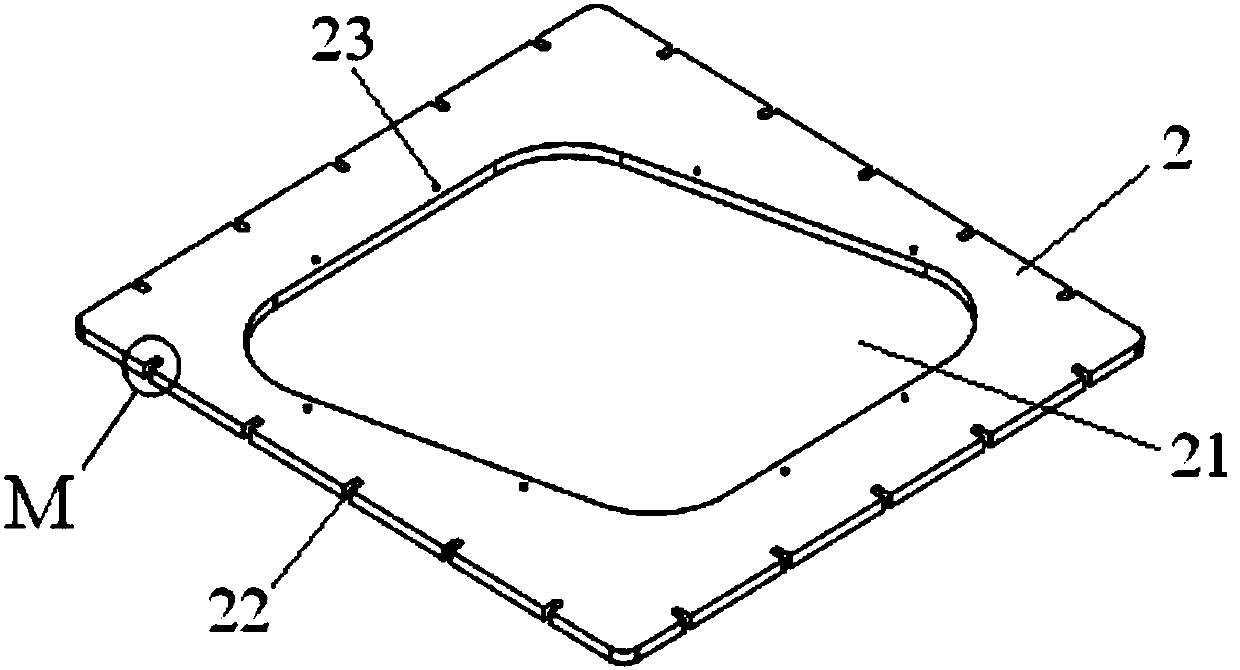

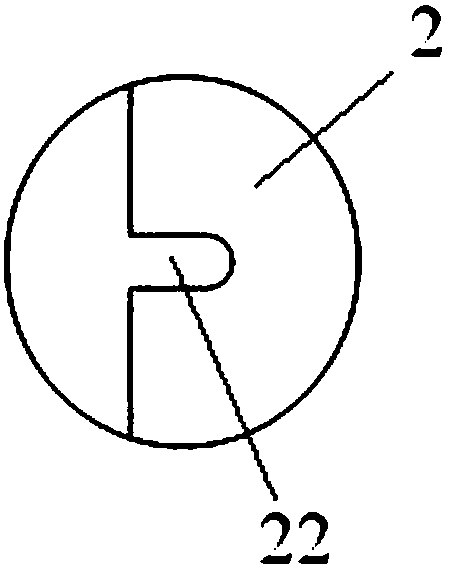

PendingCN107817179ACompact structureCycle controllableVehicle testingMaterial strength using repeated/pulsating forcesSash windowWindow opening

The invention provides a locomotive side window durability testing device which comprises a rack (1), and a side window fixing plate (3) and a side window opening / closing drive mechanism which are arranged on the rack, wherein an inner hole (21) fitting the outer contour of a side window frame (3) is formed in the side window fixing plate; the side window opening / closing drive mechanism comprisesa connecting seat (4) and a connecting rod mechanism (5); one end of the connecting seat is connected with a side window sash (6), and the other end of the connecting seat is hinged with the connecting rod mechanism; the connecting rod mechanism comprises a drive rod (51) and a connecting rod (52); the drive rod is connected with a driving device (53); and the driving device is used for driving the drive rod to swing in a reciprocating manner to repeatedly open and close the side window so as to further implement a durability test. The testing device disclosed by the invention has the advantages of simple and compact structure, controllable cycle, excellent reliability and the like, is capable of greatly improving the durability testing verification efficiency and is very convenient to mount and operate.

Owner:ZHUZHOU LINCE GRP +1

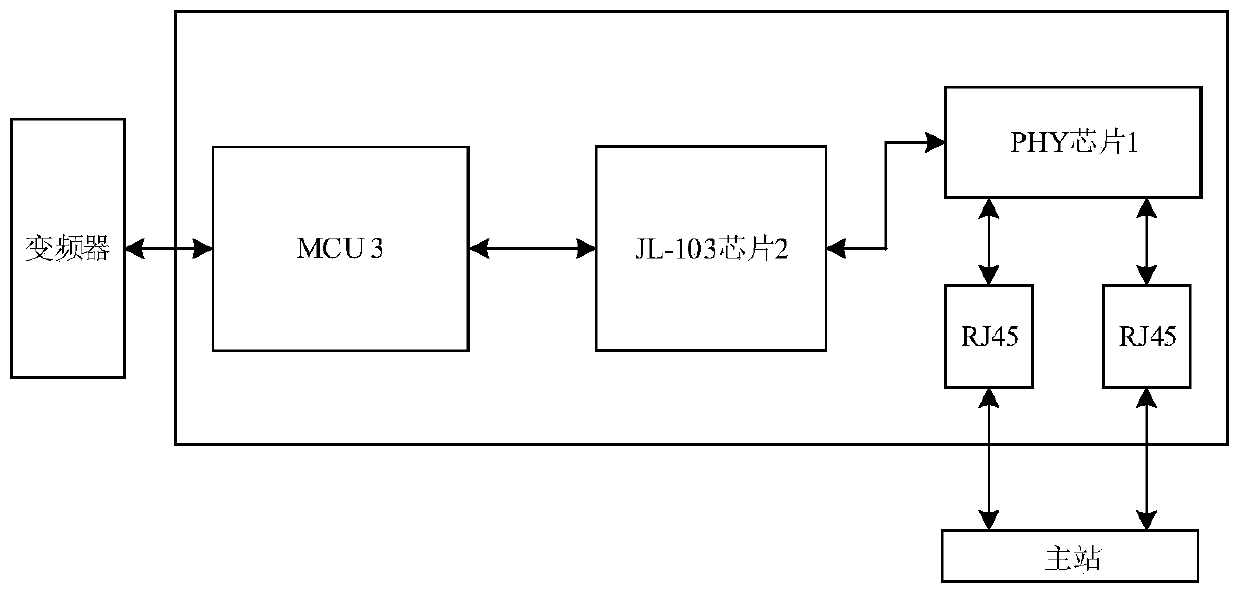

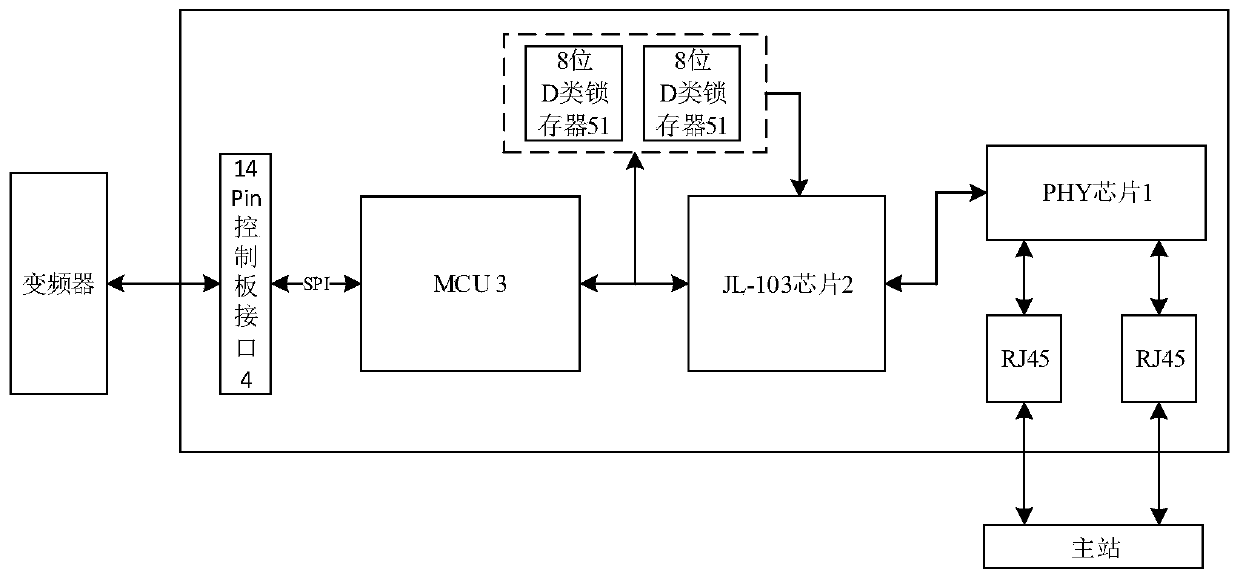

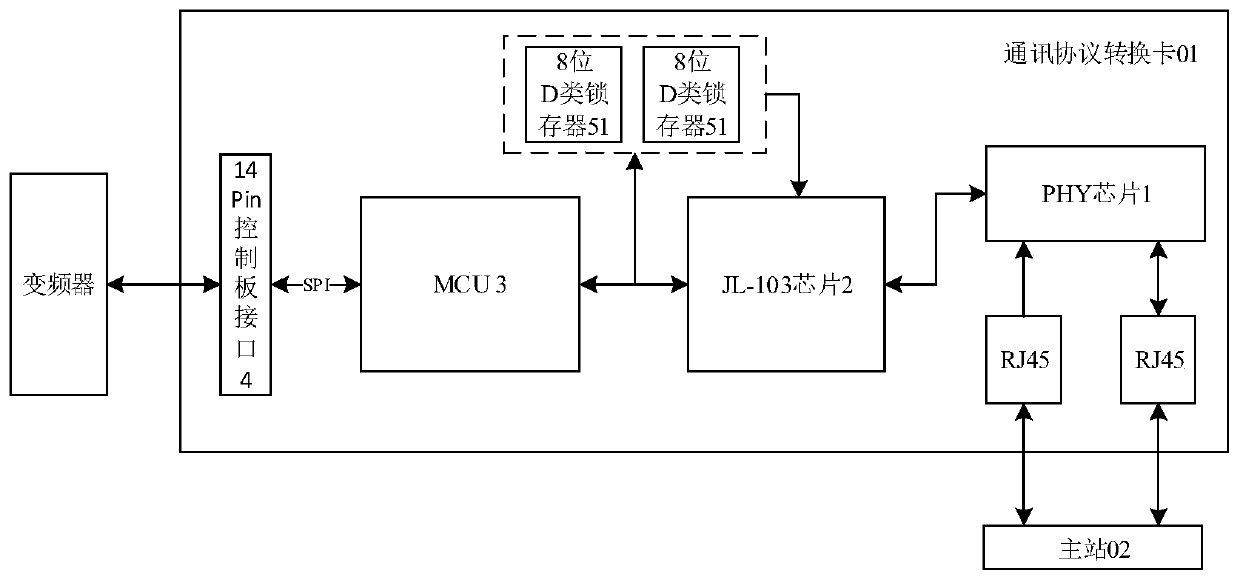

Communication protocol conversion card and communication protocol conversion system

The invention discloses a communication protocol conversion card and a communication protocol conversion system,the communication protocol conversion card is applied to a frequency converter and comprises a PHY chip; a JL-103 chip used for obtaining a master station command through the PHY chip, preprocessing the master station command and then sending the master station command to the MCU; the JL-103 chip is also used for packaging the response data according to the MECHATROLINK III protocol and sending the response data to the main station through the PHY chip; and the MCU is used for judging whether the master station command is a self-resolvable command or not, if yes, analyzing and responding to the master station command, then generating response data, and if not, sending the master station command to the frequency converter, receiving analysis data returned by the frequency converter, and generating the response data according to the analysis data. The protocol chip JL-103 special for the Anchuan slave station is adopted to communicate with the master station, stability and reliability are achieved, the period is controllable, and the cost is low.

Owner:SHENZHEN INVT ELECTRIC

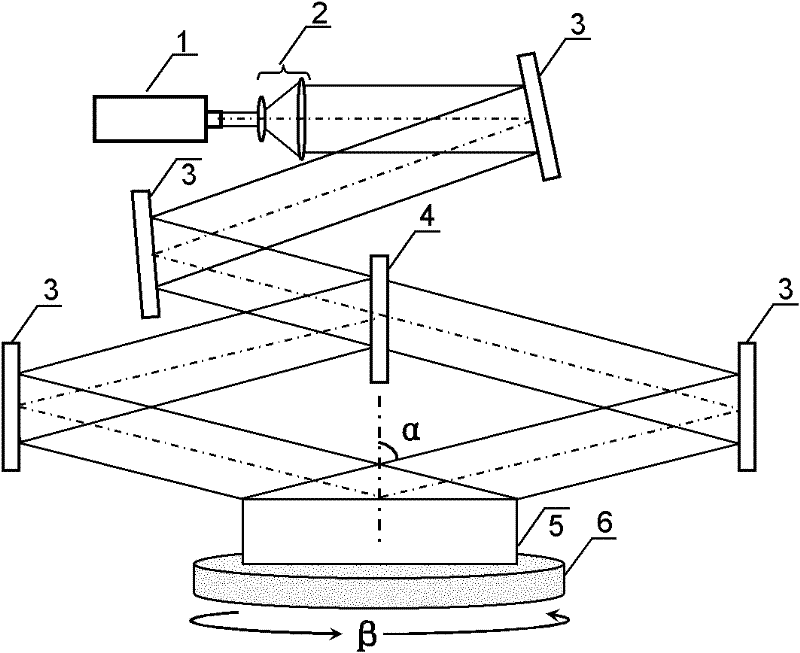

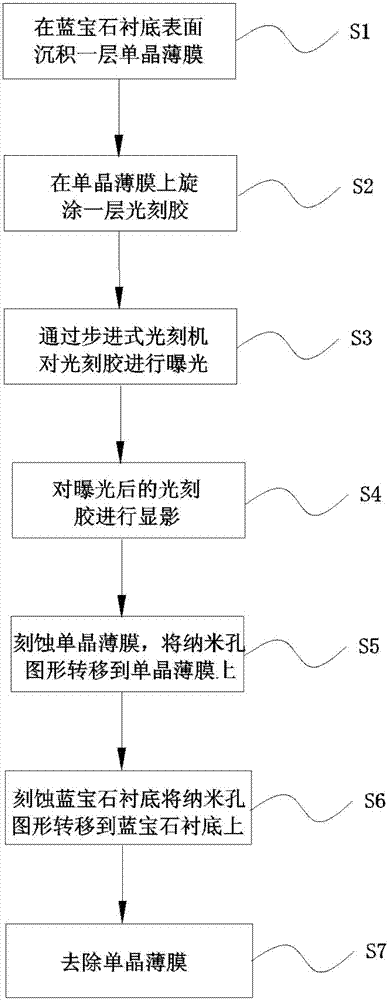

Sapphire substrate nanopore preparation method

InactiveCN107346797AUniform structureCycle controllableSemiconductor devicesSingle crystalLaser interference

The invention provides a sapphire substrate nanopore preparation method, which comprises the steps of: forming a layer of single crystal thin film on the surface of a sapphire substrate; arranging a layer of photoresist on the single crystal thin film through spin-coating; exposing the photoresist by means of a photoetching machine; developing the exposed photoresist to form a nanopore pattern; carrying out dry etching on the single crystal thin film by taking the photoresist on which the nanopore pattern is formed as a mask, and transferring the nanopore pattern onto the single crystal thin film; removing the photoresist, carrying out dry etching on the sapphire substrate by taking the single crystal thin film on which the nanopore pattern is formed as a mask, and transferring the nanopore pattern onto the sapphire substrate; and removing the single crystal thin film. According to the sapphire substrate nanopore preparation method provided by the invention, the nanopore slicing block patterned sapphire substrate having the advantages of uniform structure, controllable period, controllable duty ratio and low cost can be realized quickly through combining the laser interference photoetching technology with the dry etching technology.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Solution method preparation for metal photon crystal

InactiveCN101487976BLow costGood repeatabilityPhotomechanical apparatusOptical light guidesResistGrating

The solution method for preparing metal photonic crystal belongs to the technical field of nano photoelectron materials and devices thereof. The existing method for preparing metal photonic crystal is faced with the problems such as high cost, low efficiency and small area of preparation, etc. In the invention, sequentially, optical resist is rotatably coated on a substrate; the interference photolithography is adopted to prepare one-dimensional or two-dimensional nano optical grating structures; metal nano particle sol is rotatably coated and goes through low temperature heat treatment, thusobtaining the metal photonic crystal. The invention has the advantages of low cost, high efficiency and preparation of the metal photonic crystal in a large acreage and the like.

Owner:BEIJING UNIV OF TECH

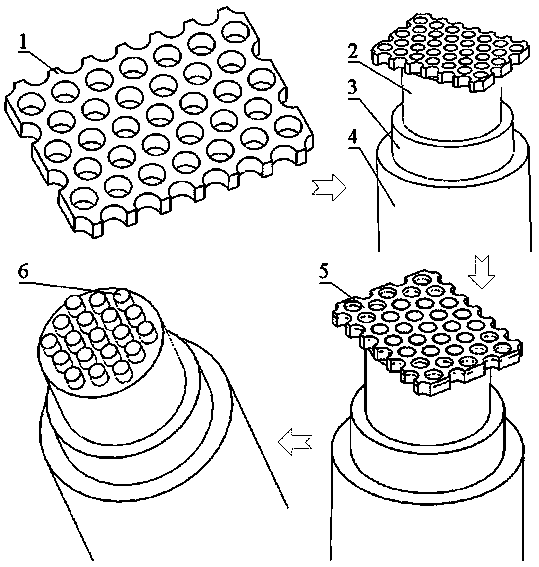

Method of uniformly preparing gold nanodisk array on end face of flat-end optical fiber in large area

The invention discloses a method of uniformly preparing a gold nanodisk array on the end face of a flat-end optical fiber in a large area, and belongs to the technical field of micro-nano machining. According to the technical scheme, a phase step refractive index multimode optical fiber with the fiber core diameter of 110 microns is used; a two-step anodic treatment method is adopted to prepare anultra-thin highly ordered AAO template; and by accurate controlling the time of secondary anodizing treatment and corrosion of a phosphoric acid solution, the period of the template is finally determined to be 700 nm, the thickness of the template is 100 nm, and the hole diameter of the template is 200 nm, and the corresponding formed nanodisk array has the same period, the thickness and the diameter. The method has the advantages of being low in cost, simple to manufacture, controllable in the period, good in repeatability and the like so that the gold nanodisk array which are orderly arranged can be simply prepared on the end face of the optical fiber in the large area.

Owner:HENAN NORMAL UNIV

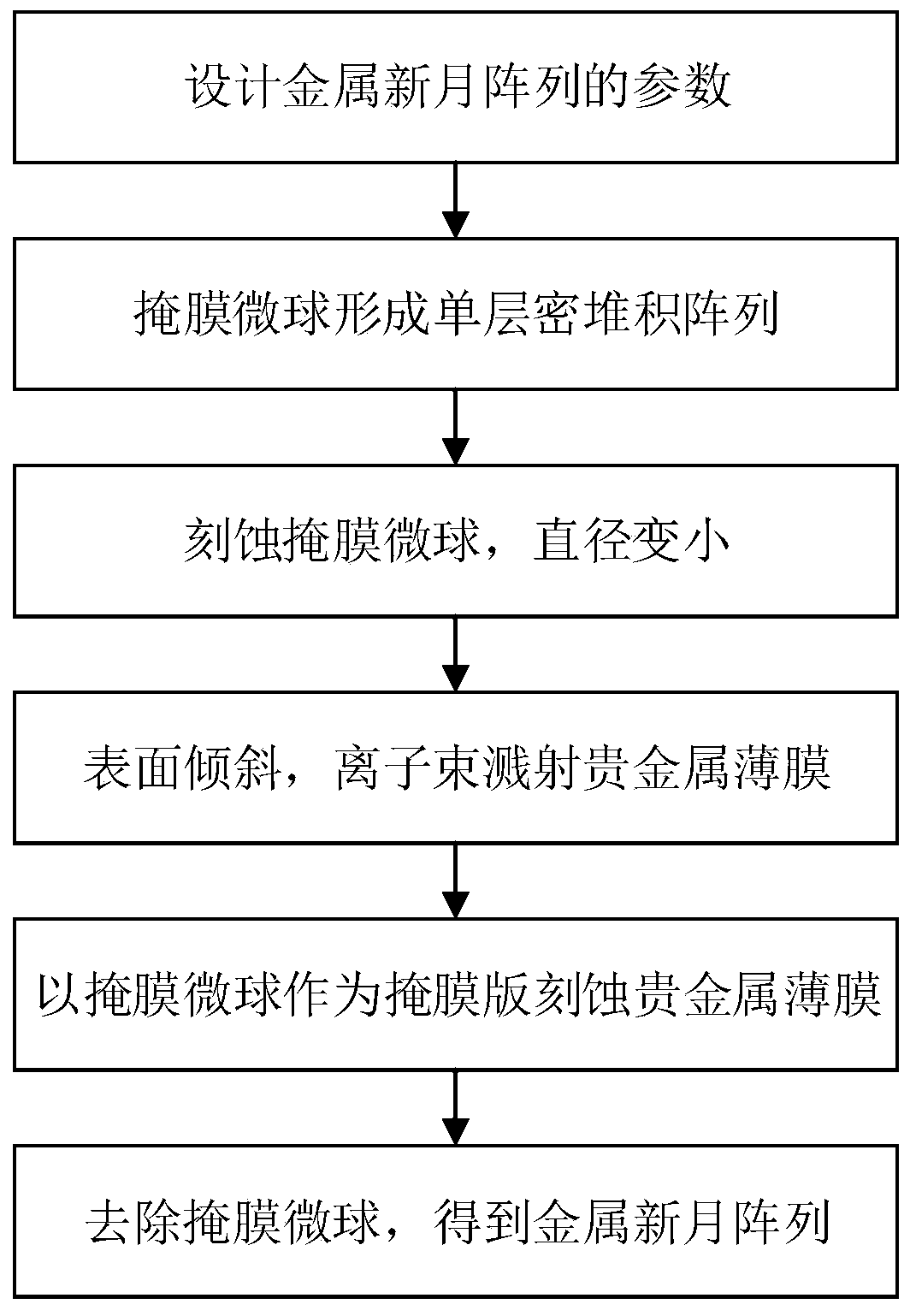

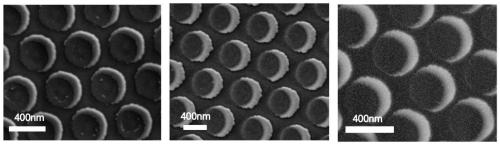

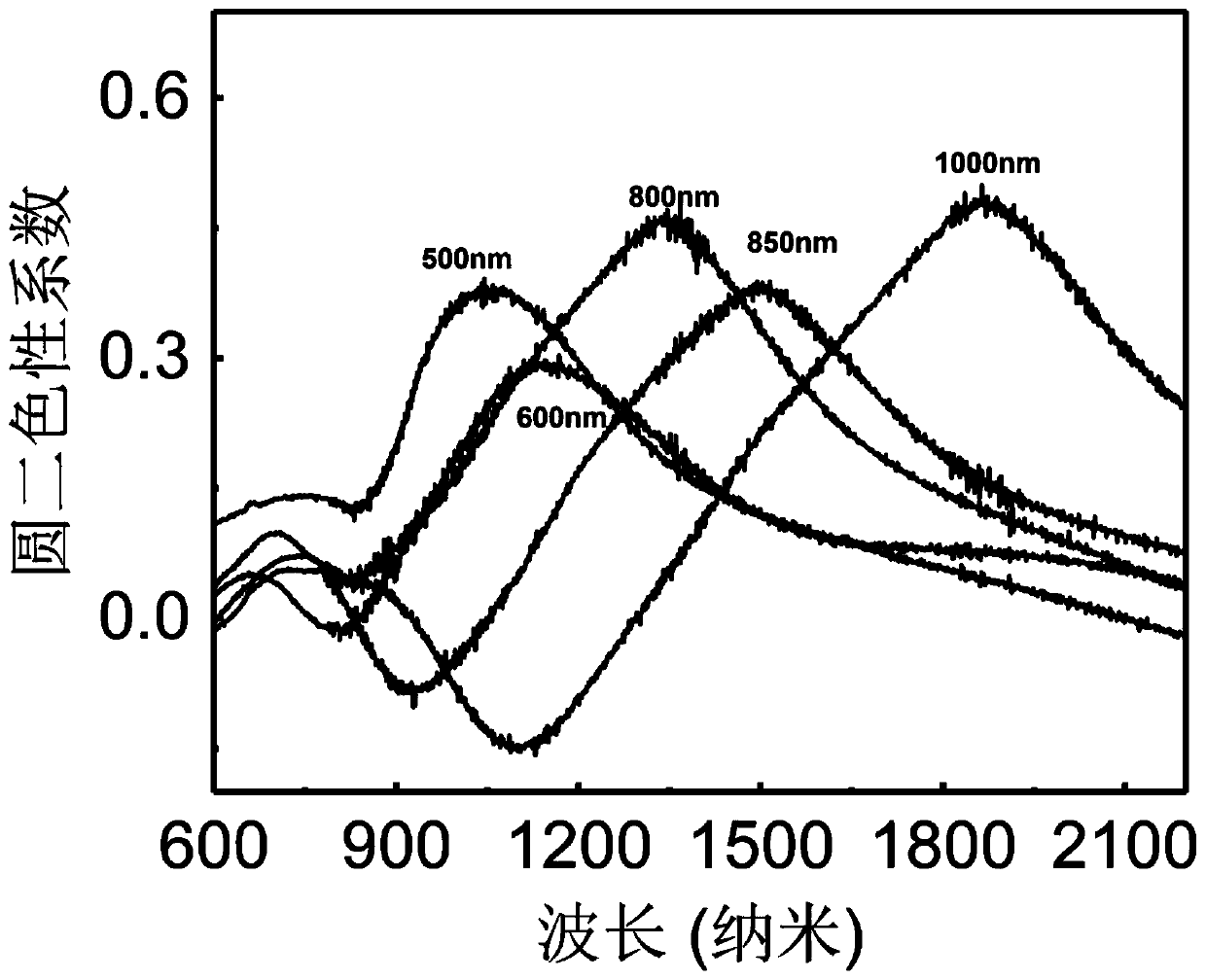

High-performance circular polarization dichromatic device and method with enhanced chirality optical response in surface

InactiveCN110261951AEasy to operateMature technologyVacuum evaporation coatingPolarising elementsMicrosphereIon beam

The invention discloses a high-performance circular polarization dichromatic device and method with enhanced chirality optical response in the surface. Ion beams sputters precious metal in the surface with an inclination angle of a substrate, a precious metal film is sputtered in part of a projection area vertical to the surface of the substrate of mask microspheres, the mask microspheres as a reticle etches area not covered by the mask microspheres of the precious metal film, the precious metal film exposed between adjusted mask microphones is etched, precious metal in the projection area vertical to the substrate surface of the mask microspheres is reserved, and the mask microspheres are removed to obtain a metal crescent array formed on the substrate. The period controllable metal crescent array has the advantages of large area, low cost, high circular dichromatic optical activity, tunable response waveband, uniform and environment protective, and can satisfy needs for theoretical research and practical application; and thus, a strong tool and solid basis are provided for theoretical research and practical application of chirality optics.

Owner:NANKAI UNIV

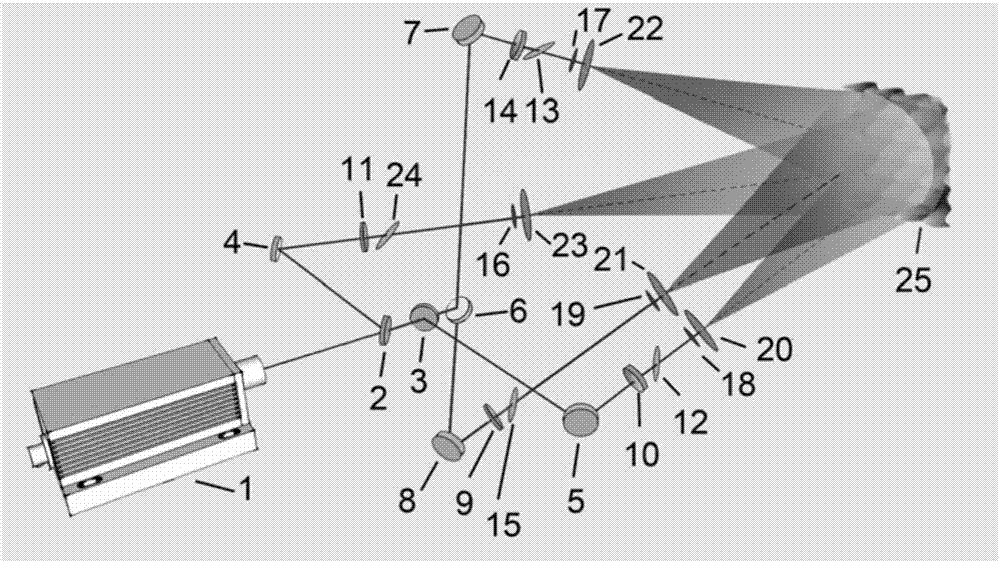

Maskless preparation device and method of a chalcogenide optical fiber grating

ActiveCN105954832BCycle controllableSimple structureCladded optical fibrePhotomechanical exposure apparatusFiberBeam splitter

The invention discloses a chalcogenide fiber grating maskless preparation device and method. The device comprises a laser light source, an attenuation slice, a laser light source collimation optical system, a digital micromirror device, a beam splitter mirror, an imaging optical system, a mobile working platform, a CCD and a computer. The maskless preparation device is simple in structure and efficient, does not need an expensive mask plate, is low in cost and is high in operability; when a chalcogenide fiber grating is prepared by utilizing the device, features of the digital micromirror device can be utilized fully, and dynamic images can be generated through the digital micromirror device; compared with a conventional method, the preparation method is simpler; a conventional mask plate is replaced, thereby preventing the defect that the mask plate cannot be in repetitive cycle use, and saving resources; the preparation device is flexible to operate; writing period of the fiber grating is controllable; and finally, high-efficiency and maskless writing of the chalcogenide fiber grating is realized, and uniform-structure or non-uniform-structure fiber grating is obtained. The device and method have better practical value and application prospect.

Owner:NINGBO UNIV

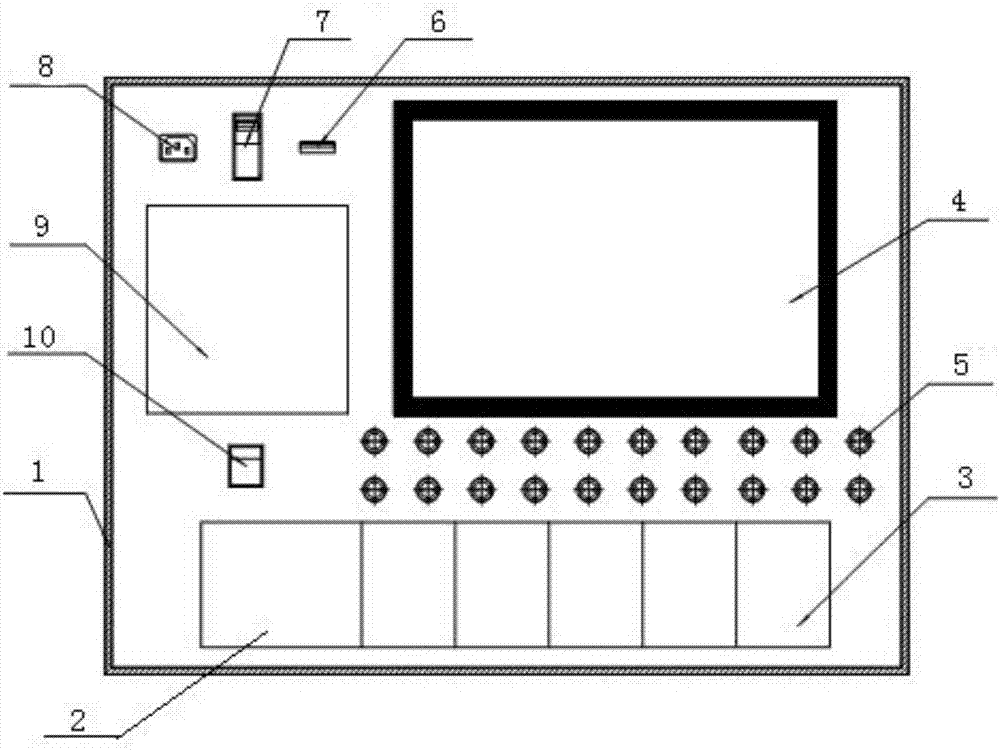

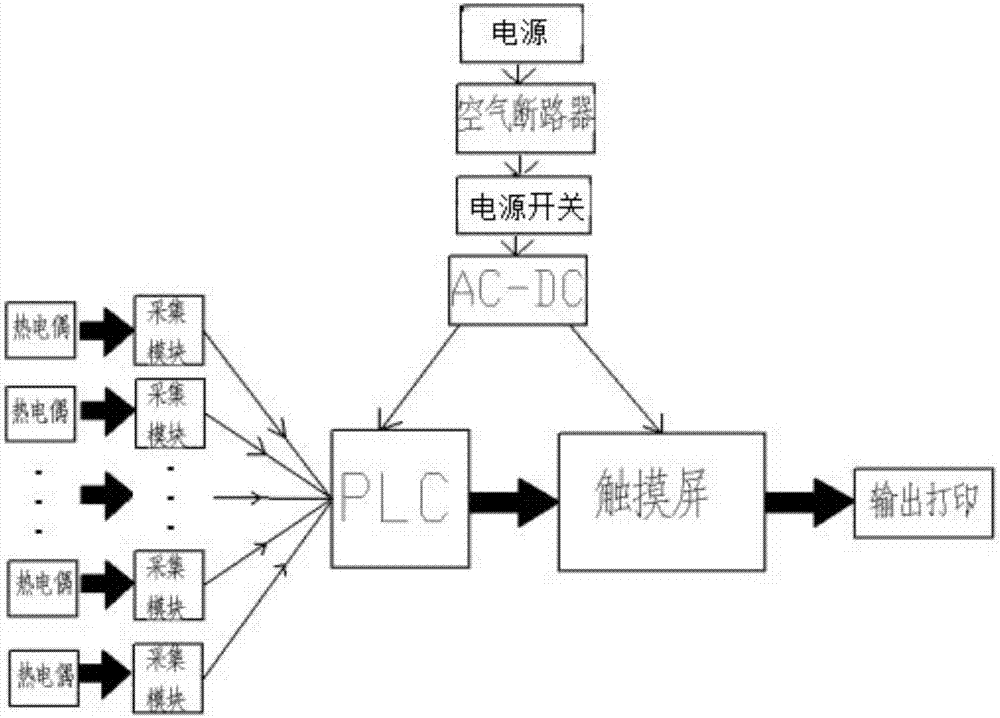

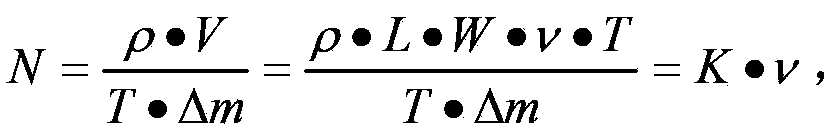

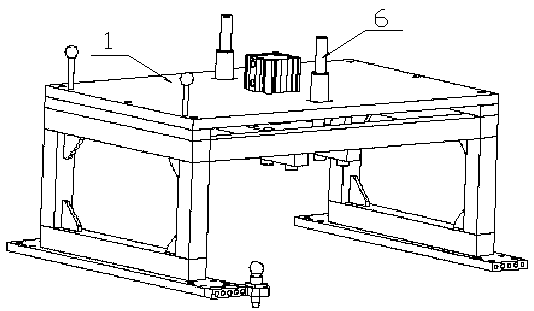

Heater unit temperature field acquisition test equipment based on PLC

PendingCN107884088AEasy to moveEasy to carryThermometers using electric/magnetic elementsUsing electrical meansConvertersProcess engineering

The invention provides heater unit temperature field acquisition test equipment based on a PLC; the equipment mainly comprises a draw-bar box; a power supply, a touch screen, the PLC, a plurality of temperature sensors and a plurality of paths of temperature acquisition modules are arranged in the draw-bar box; all electric parts are integrated on one mounting plate, and embedded and fixed in thedraw-bar box; a switch power supply converts the commercial power AC 220V into a DC 24 V power supply through an AC / DC converter, thus powering up the touch screen and the PLC. The temperature sensorsgather the heater unit temperature field surface temperature; the temperature acquisition modules can upload the gathered data to the PLC; the touch screen stores and outputs the temperature of eachacquisition point and a change curve. The test equipment is simple and compact in structure, controllable in period, good in reliability, easy to control, and can realize multi-point real time data acquisition, thus greatly improving the heater unit temperature field test verification efficiency.

Owner:ZHUZHOU LINCE GRP +1

Full-automatic commercial pure titanium smelting method adopting electron beam cold hearth furnace

The invention relates to a full-automatic TA1 smelting method adopting an electron beam cold hearth furnace and belongs to the technical field of production engineering application. The production method comprises the following steps: drying and putting titanium sponge into an Archimedean screw tube which is mounted into a feeding system of an electron beam cold hearth melting furnace (EB furnace for short), wherein different rotary speeds are set; when the degree of vacuum of the feeding system reaches 0.4-0.8 Pa and the degree of vacuum of a main smelting cold hearth reaches 0.05-0.8 Pa, starting the feeding system to feed the titanium sponge into the smelting cold hearth of a main smelting chamber; triggering an electron gun to melt the titanium sponge into liquid titanium which flows through a primary refining cold hearth and a main refining cold hearth and then into a rectangular withdrawing crucible; controlling the rotary speed of the Archimedean screw tube to control the feeding speed and scanning patterns so as to control the melting speed, and the ingot pulling rate thereby realizing full-automatic control. The method has the advantages of good ingoting quality, high one-step yield, low manufacturing cost, controllable production period, simplicity in operation, energy conservation, environmental protection and high repeatability.

Owner:YUNNAN TITANIUM IND

Milling device for cell pole faces of lithium batteries

PendingCN108746784AImprove working conditionsImprove product qualityWork clamping meansFeeding apparatusEngineeringMechanical engineering

The invention discloses a milling device for cell pole faces of lithium batteries. The milling device comprises a portal mechanism, a trapezoidal lead screw mechanism and an electric spindle. An X-axis clamping mechanism is arranged on one side of the portal mechanism. An X-axis positioning mechanism is arranged at the other end of the X-axis clamping mechanism. A Y-axis clamping mechanism is arranged on one side of the X-axis clamping mechanism. A Y-axis positioning mechanism is arranged at the other end of the Y-axis clamping mechanism. A Z-axis positioning mechanism is arranged at the upperend of the portal mechanism. A dedusting device is arranged at the lower end of the portal mechanism. A servo motor A is arranged on the inner side of the portal mechanism. According to the milling device for the cell pole faces of the lithium batteries, the product quality can be improved, and quality stability is ensured; the labor productivity is improved; the working condition of operators isimproved, the product cycle is clear, and the product quality is easy to control; and the model changing and updating cycle of products can be shortened, and corresponding equipment investment is reduced; and automatic mass production of the products can be achieved.

Owner:宁德思客琦智能装备有限公司

A strain of coronoid cyst, its breeding method and its application

ActiveCN105368716BImprove qualityStable flowering processFungiPre-extraction tea treatmentMicroorganismFermentation

The invention belongs to the technical field of microorganisms and food biology, and particularly relates to a eurotium cristatum strain which has been preserved in the common microorganism center of the China Committee for Culture Collection of Microorganisms, and the preservation number of the eurotium cristatum strain is CGMCC NO.11304. Strict breeding authentication shows that the eurotium cristatum strain has a series of characteristics suitable for tea leaf production and fermentation and can be used for producing various golden flower tea leaves such as golden flower dark tea, golden flower Liupu tea, golden flower Pu'er tea and golden flower clovershrub tea, and produced tea leaves are clear in characteristic and good in quality.

Owner:中国土产畜产进出口有限责任公司

A kind of standardized production process of Jinhua Liubao tea

ActiveCN105394233BImprove qualityFlowering process is stablePre-extraction tea treatmentMicroorganismFermentation

The present invention belongs to the technical field of microorganisms and food biology, and particularly relates to a Eurotium cristatum Liupao tea standardization production process, which comprises a Eurotium cristatum fermentation step, wherein the key step of the Eurotium cristatum fermentation step is carrying out single strain fermentation on Eurotium cristatum having a preservation number of CGMCC NO.11040. According to the present invention, the prepared Zhongchajiaocang Liupao tea product can achieve the stable Eurotium cristatum fermentation so as to achieve the controlled number of the Eurotium cristatum in the Liupao tea product, the quality is stable, and the feature is distinctive.

Owner:中国土产畜产进出口有限责任公司

A gold nanoring stacked array substrate with surface-enhanced Raman scattering and its preparation method

ActiveCN107966429BSimple processSimple technologyRaman scatteringPhotomechanical exposure apparatusGold filmPhotoresist

The invention discloses a gold nano-ring stacked array substrate with surface-enhanced Raman scattering and a preparation method. The standing wave effect in the photolithography process is utilized, that is, the surface reflection of the incident light substrate material interferes with the incident light, and the photoresist At the same time, the multi-beam laser interference lithography technology arranges the stacked three-dimensional structure according to the specified periodic distribution, and then sputters a nanometer-thick gold film to form a gold nanoring stack. The structure has the effect of surface-enhanced Raman scattering, and can be used as a base material for Raman scattering detection, thereby effectively improving the Raman signal of the detected substance.

Owner:CHANGCHUN UNIV OF SCI & TECH

Photonic crystal micro-nano structure direct-writing method based on metal nanoparticles

Owner:BEIJING UNIV OF TECH

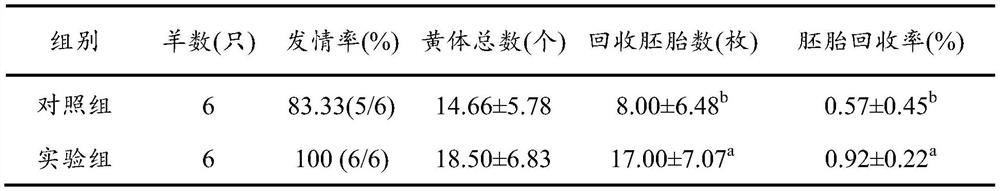

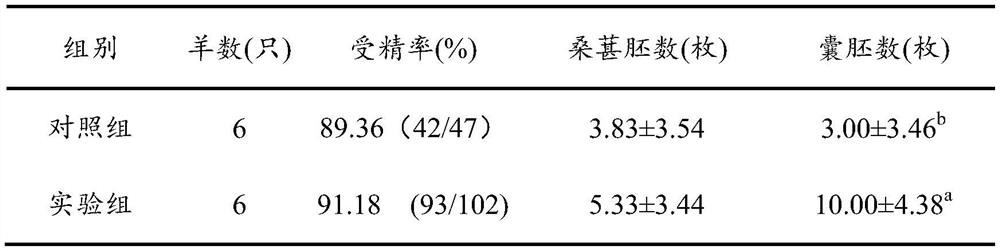

Method for improving superovulation efficiency of livestock

PendingCN114569281AEasy to produceReduce irritabilityAnimal reproductionAnimal scienceProstaglandin F2alpha

The invention provides a method for improving the breeding efficiency of livestock. Specifically, the invention provides an application of prostaglandin F2alpha or a homologue thereof in improving the superovulation efficiency of livestock, and a method for improving the superovulation efficiency of the livestock.

Owner:CHINA AGRI UNIV

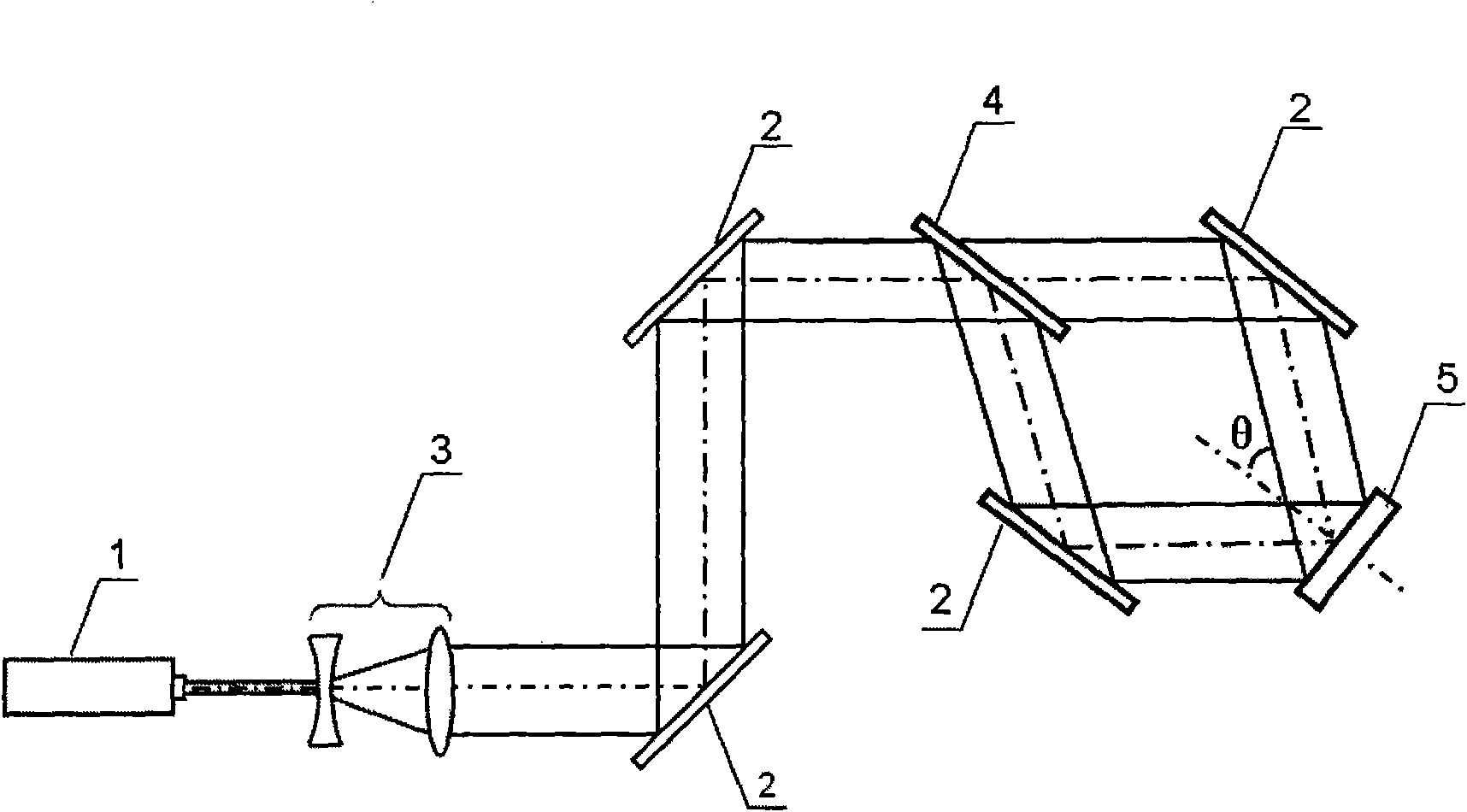

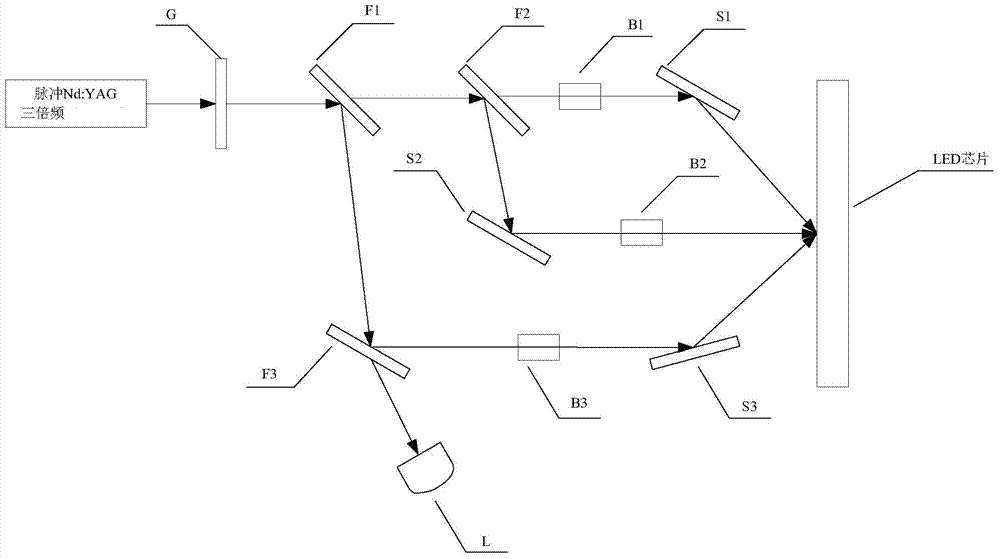

A kind of preparation method of LED photonic crystal

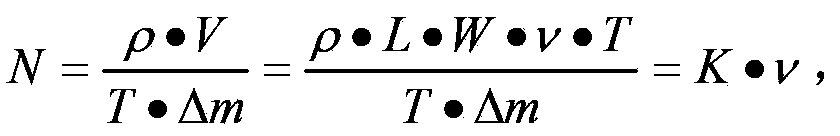

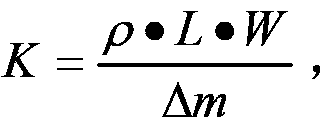

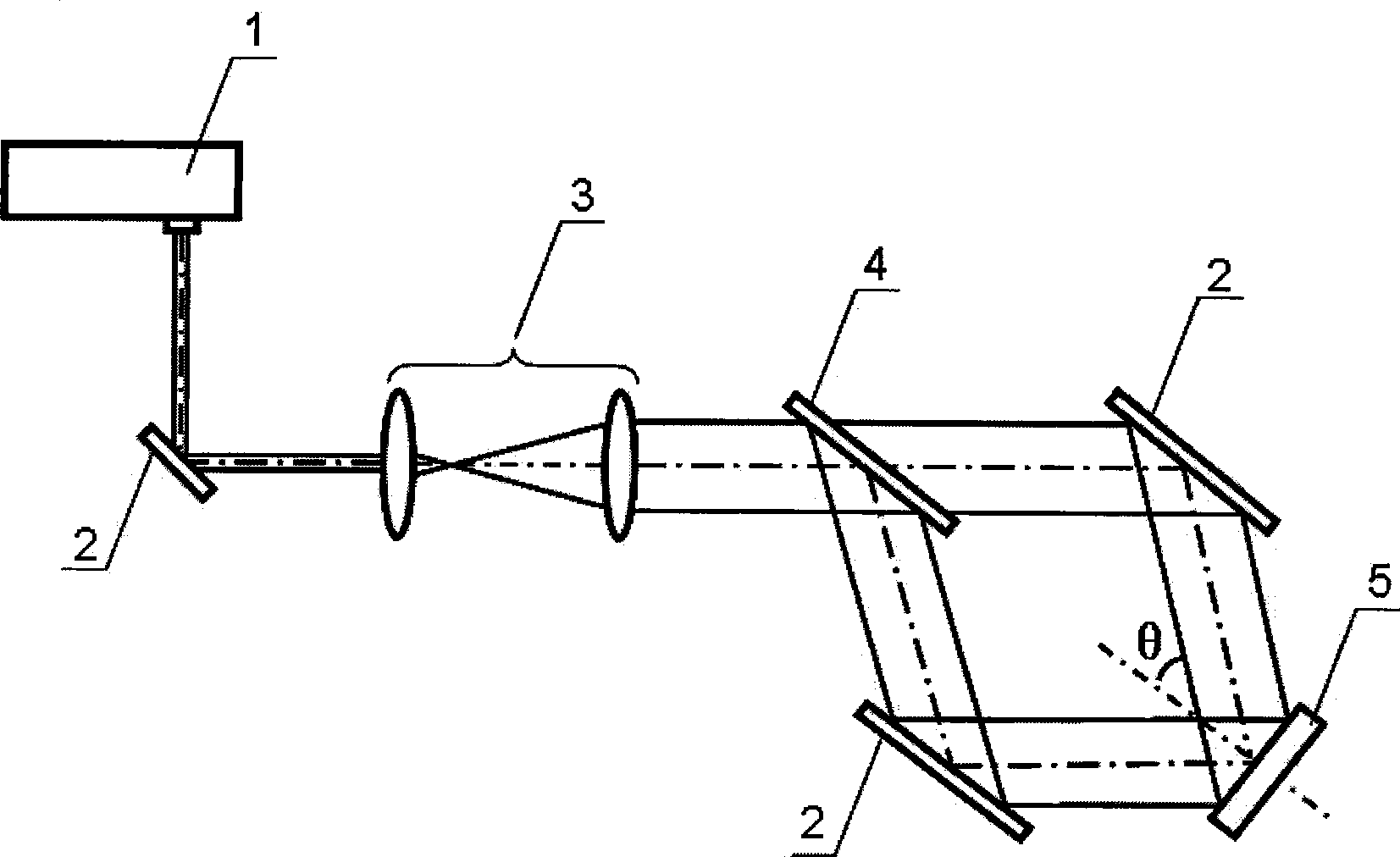

The invention relates to a preparation method of an LED photonic crystal. The method comprises the steps of splitting a triple-frequency laser beam of Nd: YAG laser, which is used as direct etching laser and the wavelength of which is gamma, into three coherent laser beams, wherein every two coherent laser beams form an identical angle theta, each coherent laser beam is identical in polarization direction, and converging the three coherent laser beams onto a transparent electrode film of an LED chip; applying one or more pulses to the Nd: YAG laser, and finally forming the photonic crystal with a given period T and given porosity. By adopting the method, the photonic crystal can be prepared on the surface of the chip in one step, the process is simple, convenience and rapidness can be realized, and the steps such as masking and after-treatment are not needed; the prepared photonic crystal is controllable in period, and the photonic crystal with the period of 300nm to 300 micrometers can be obtained by changing the range of the angle theta; the processing area is large, the processing cost is low, and the method is applicable to batch and mass production.

Owner:DALIAN NATIONALITIES UNIVERSITY

A method for uniformly preparing gold nanodisk arrays in a large area on the end face of a flat optical fiber

The invention discloses a method of uniformly preparing a gold nanodisk array on the end face of a flat-end optical fiber in a large area, and belongs to the technical field of micro-nano machining. According to the technical scheme, a phase step refractive index multimode optical fiber with the fiber core diameter of 110 microns is used; a two-step anodic treatment method is adopted to prepare anultra-thin highly ordered AAO template; and by accurate controlling the time of secondary anodizing treatment and corrosion of a phosphoric acid solution, the period of the template is finally determined to be 700 nm, the thickness of the template is 100 nm, and the hole diameter of the template is 200 nm, and the corresponding formed nanodisk array has the same period, the thickness and the diameter. The method has the advantages of being low in cost, simple to manufacture, controllable in the period, good in repeatability and the like so that the gold nanodisk array which are orderly arranged can be simply prepared on the end face of the optical fiber in the large area.

Owner:HENAN NORMAL UNIV

Method for preparing micron/submicron metal ring and open-mouth metal ring

InactiveCN100494045CAdjustable thicknessCycle controllableSemi-permeable membranesVolume/mass flow by thermal effectsHydrofluoric acidAlcohol

The invention discloses a preparing method of the micro / sub-micron ferrule and the open ferrule. It gets the two-dimensional colloid crystal by the self-organizing technology, then to anneal in high temperature, chemical corruption, the secondary anneal in high temperature to form the non close-packed two-dimensional structure; the polymer is filled into lattice space to form the compound film which is put in the hydrofluoric acid steam to go on the secondary corrosion and form the ring space; the surface of the compound module is spurted by metal, then to resolve the compound module to get the ferrule array structure. If the sample is dipped into the alcohol solution to make the ring space change the partiality ring space; then to spurt by metal and remove the compound module to get the open ferrule. The advance of the invention is: the structural parameter can be controlled; the inner and outer diameter of the ferrule and the open ring can be adjusted and the circle can be controlled; the single disperse character is good and the thickness is uniform; the interface is clear and the technology is simple.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com