Solution method preparation for metal photon crystal

A metal photonic crystal and solution method technology, applied in the field of nano-optoelectronic materials and devices, can solve the problems of limiting the wide application of metal photonic crystals, low preparation efficiency, and small preparation area, and achieve low cost, high preparation efficiency, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Fabrication of waveguide-coupled one-dimensional nanowire gold photonic crystal structures

[0030] The photoresist used in this embodiment is positive photoresist S1805 produced by Germany ROHM & HAAS company; the substrate is a glass plate coated with a 200nm ITO waveguide layer.

[0031] 1) Spin-coat the photoresist S1805 on the surface of the ITO by spin-coating at a speed of 1500rpm to obtain a photoresist film with a thickness of 200nm;

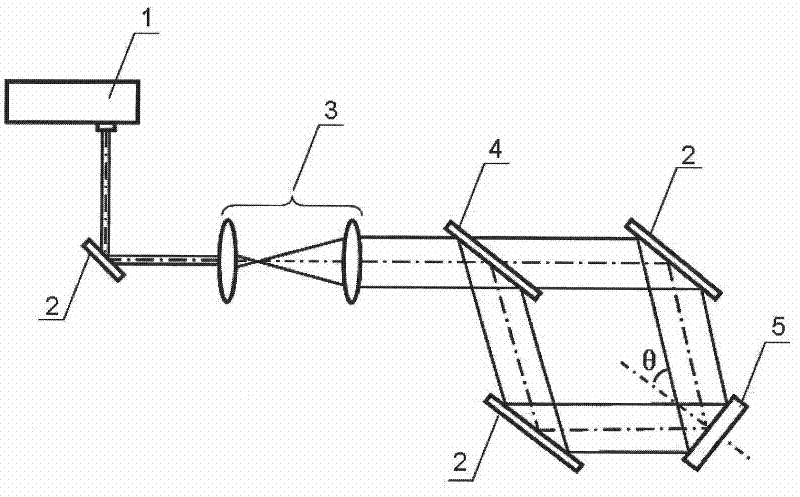

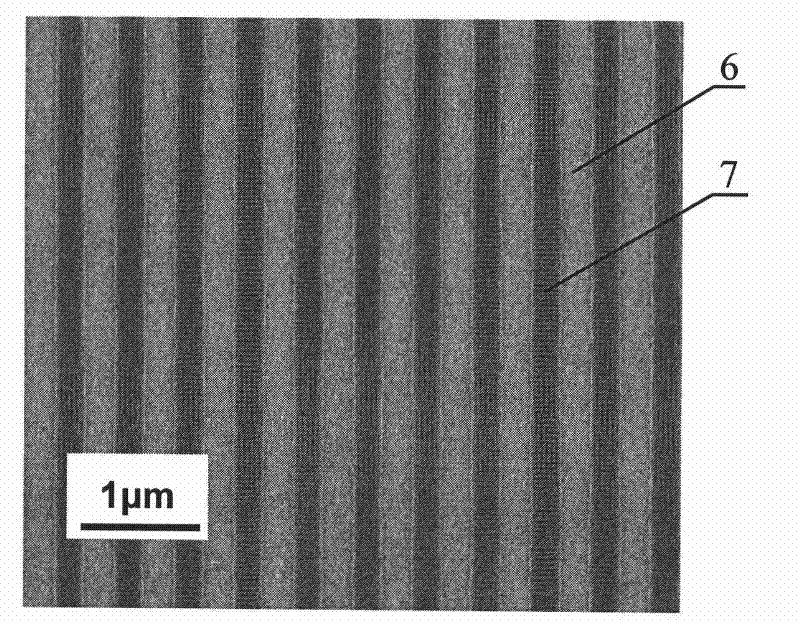

[0032] 2) Use such as figure 1 The optical path of the interference lithography is shown, wherein the θ angle in the interference optical path is 19.5 degrees, and the output power of the laser is 0.1mW. The sample is placed in figure 1 On the sample rack shown, expose for 3s, develop for 8s with developing solution, and obtain a one-dimensional photoresist nano-grating structure, such as figure 2 As shown, the period of the grating structure is 500nm;

[0033] 3) After preparing gold nanoparticles with a diameter of 2-7nm wi...

Embodiment 2

[0037] Preparation of two-dimensional nanopillar gold photonic crystal structure

[0038] The photoresist used in this embodiment is a negative photoresist ma-N405 produced by Microresist Company of Germany; the substrate is a glass sheet.

[0039] 1) The photoresist ma-N405 is spin-coated on the surface of the glass by the method of spin coating, and the rotation speed is 2000rpm to obtain a photoresist film with a thickness of 150nm;

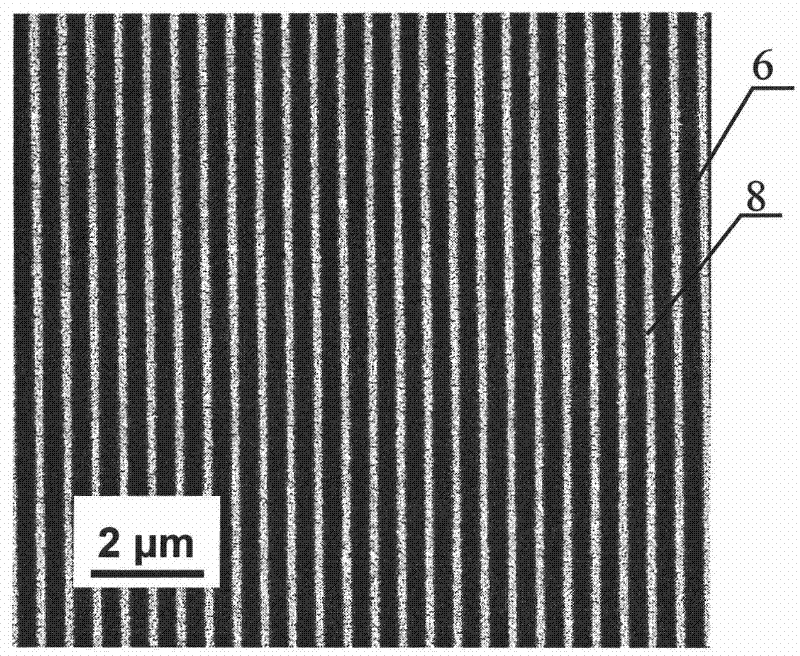

[0040] 2) Use such as figure 1 The optical path of the interference lithography shown, wherein, the θ angle in the interference optical path is 28 degrees, the light output power of the laser is 0.1mW, the sample is placed in figure 1 On the sample rack shown, expose for 2s, rotate the sample 90 degrees for secondary exposure, develop with developer for 4s, and obtain a two-dimensional photoresist nanohole grating structure, the period of the two-dimensional grating structure is 330nm;

[0041] 3) After preparing gold nanoparticles with a di...

Embodiment 3

[0045] Fabrication of Waveguide-Coupled Two-Dimensional Nanohole Gold Photonic Crystal Structures

[0046] The photoresist used in this embodiment is positive photoresist S1805 produced by Germany ROHM & HAAS company; the substrate is a glass plate coated with a 200nm ITO waveguide layer.

[0047] 1) Spin-coat the photoresist S1805 on the surface of the ITO by spin-coating at a speed of 4000rpm to obtain a photoresist film with a thickness of 50nm;

[0048] 2) Use such as figure 1 The optical path of the interference lithography shown, wherein, the θ angle in the interference optical path is 28 degrees, the light output power of the laser is 0.1mW, the sample is placed in figure 1 On the sample rack shown, expose for 2s, rotate the sample 90 degrees for secondary exposure, develop with developer for 4s, and obtain a two-dimensional photoresist nanopillar grating structure, the period of the two-dimensional grating structure is 330nm;

[0049] 3) After preparing gold nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com