System and method for preparing micro-nano optical fiber Bragg gratings

A technology of Bragg gratings and micro-nano fibers, applied in the field of gratings, can solve the problems of expensive grating equipment and long preparation period, and achieve the effects of low price, simple preparation process and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

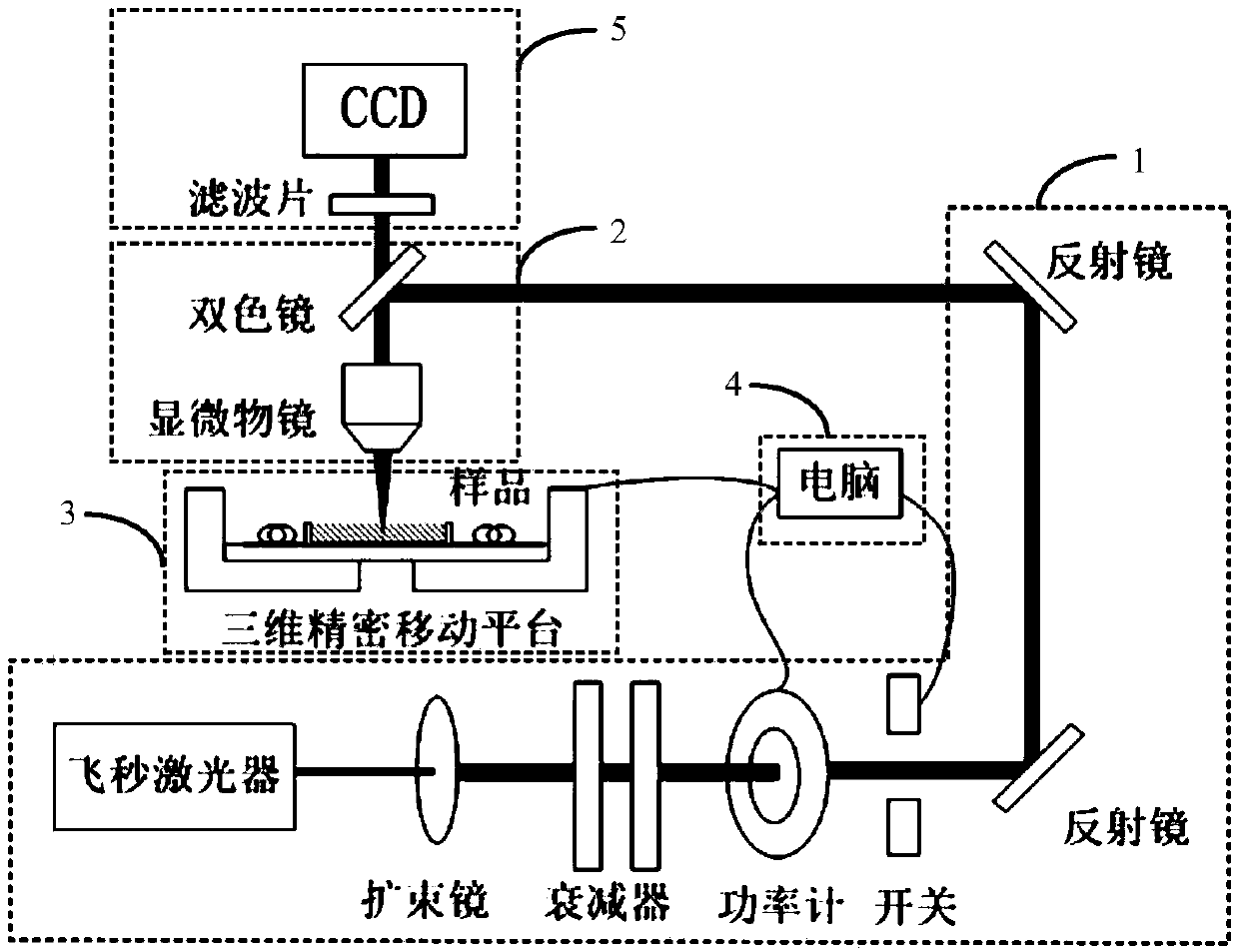

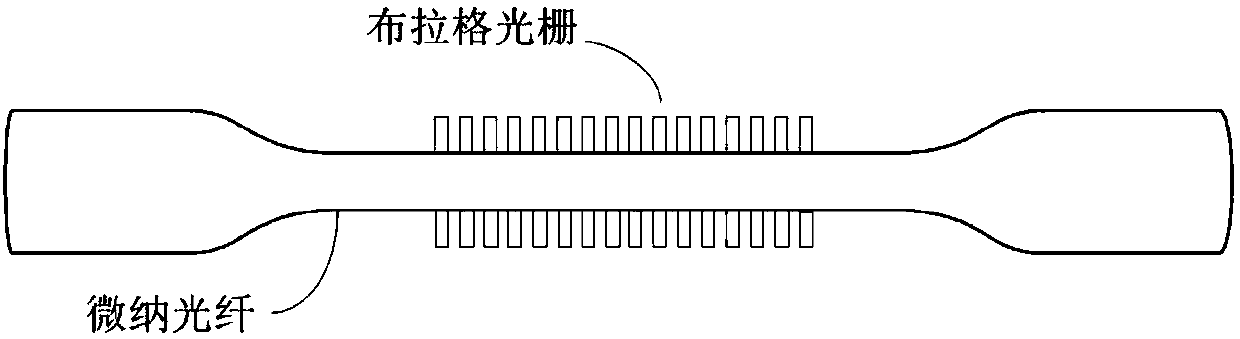

[0067] Figure 4 It shows the preparation method for preparing micro-nano fiber Bragg grating through the above-mentioned micro-nano fiber Bragg grating preparation system provided by the embodiment of the present invention, including:

[0068] S401, preparing a micro-nano optical fiber with a preset diameter by using an optical fiber tapering method. In this step, a micro-nano optical fiber with a diameter of less than 4 microns is prepared by using a traditional fiber tapering method.

[0069] S402, fixing the micro-nano optical fiber on a glass slide, uniformly coating a layer of cured glue on the micro-nano optical fiber and covering it with a cover glass to prepare a sample. In this embodiment, the glass slide is a magnesium fluoride sheet, and the micro-nano optical fiber prepared in step S401 is fixed on a clean magnesium fluoride sheet, and a layer of UV-curable glue is uniformly coated on the micro-nano optical fiber and covered with a cover slides to prepare sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com