A method for uniformly preparing gold nanodisk arrays in a large area on the end face of a flat optical fiber

A technology for preparing gold on the end face of an optical fiber, applied in the direction of nanotechnology, surface reaction electrolytic coating, metal material coating technology, etc., can solve problems such as unstable imprinting process, template damage, substrate and embossing glue falling off, etc. Achieve the effect of simple production, controllable cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

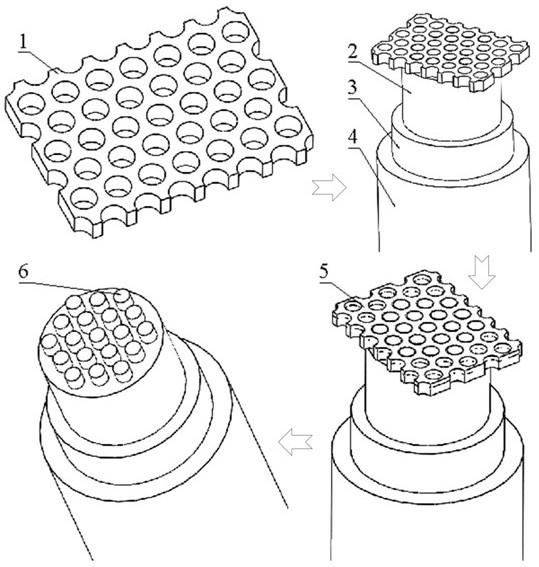

[0015] The specific content of the present invention is described in detail in conjunction with the accompanying drawings. AAO template transfer combined with electron beam evaporation deposition is used to prepare a nanodisk array on the end face of a flat-headed optical fiber. This technical solution uses a step-index multimode optical fiber with a core diameter of 110 μm. The ultra-thin and highly ordered AAO template 1 was prepared by the anodic treatment method, and the period of the template was finally determined to be 700nm, the thickness was 100nm, and the pore size was 200nm by precisely controlling the time of the second anodization treatment and phosphoric acid solution (5wt%) corrosion , the correspondingly formed nanodisk arrays have the same period, thickness and diameter. Its specific preparation process is as follows:

[0016] Step S1: Take a 2cm*2cm aluminum sheet and place it in an ultrasonic cleaning machine, wash it in ethanol, acetone and deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com