A gold nanoring stacked array substrate with surface-enhanced Raman scattering and its preparation method

A surface-enhanced Raman and array substrate technology, which is used in Raman scattering, photolithography on patterned surfaces, opto-mechanical equipment, etc., can solve the problem of not being able to meet the requirements of large area, uniformity and high enhanced signal of SERS substrates at the same time. , it is difficult to control the particle spacing and other problems, to achieve the effect of easy large-area preparation, strong Raman signal enhancement effect, and easy control of the period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

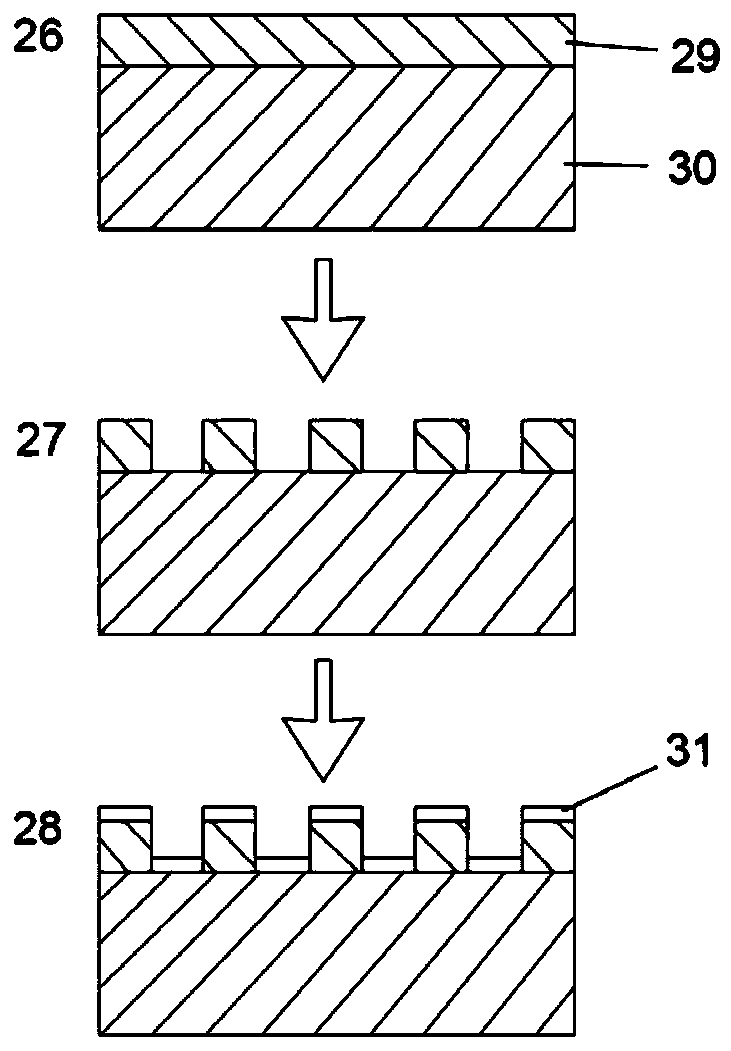

[0041] (1) cleaning the substrate, with a thickness of 1.2 mm single-sided polished silicon as the substrate material 30, its reflectivity in the visible light range is higher than 80%, it is placed in acetone, absolute ethanol, deionized water for ultrasonic cleaning, Blow dry with high-purity nitrogen for 100-150s each time, select positive photoresist 29, the type is AR-P3740 for glue coating, the resolution is 0.5μm, the rotation speed of the homogenizer is 4000r / min, and the thickness of the glue is 1.5μm, then put it on a hot plate, pre-baked at 100°C, the pre-baked time is 1min, take it off, and place it in dark conditions, such as image 3 The gluing process in is shown in 26;

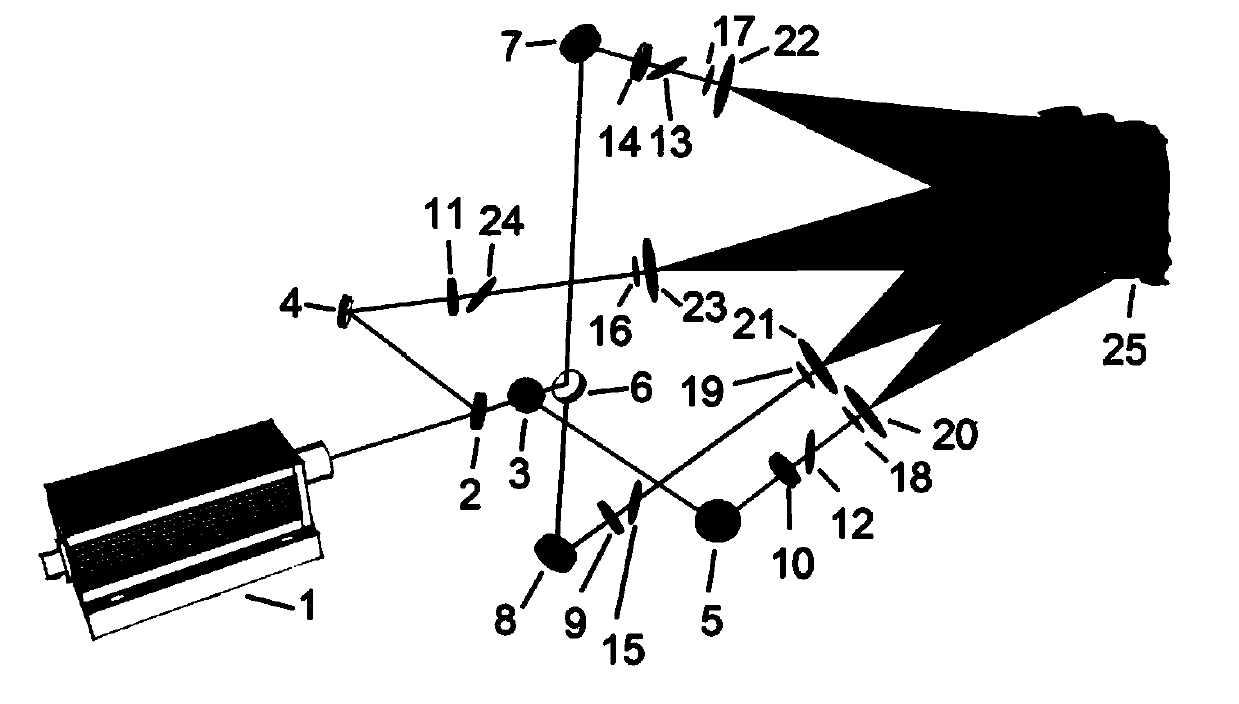

[0042] (2) Exposure is performed using a four-beam laser interference lithography system. The four-beam interference system generates modulation by controlling the incident angle. A 360nm semiconductor laser is the light source for the system, such as figure 2 As shown, the beam emitted by th...

Embodiment 2

[0047] (1) cleaning the substrate, with a thickness of 1.2 mm single-sided polished silicon as the substrate material 30, its reflectivity in the visible light range is higher than 80%, it is placed in acetone, absolute ethanol, deionized water for ultrasonic cleaning, Blow dry with high-purity nitrogen for 100-150s each time, select positive photoresist 29, the type is AR-P3740 for glue coating, the resolution is 0.5μm, the rotation speed of the homogenizer is 4000r / min, and the thickness of the glue is 1.5μm, then put it on a hot plate, pre-baked at 100°C, the pre-baked time is 1min, take it off, and place it in dark conditions, such as image 3 The gluing process in is shown in 26;

[0048] (2) Use a non-modulating three-beam interference lithography system for exposure. The incident angles of the first beam and the second beam of coherent light in the three beams are both 14°. At the same time, the spatial angles of the first beam of coherent light are respectively is 0°,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com