Preparation method for embedded micro-nano channel

A nano-channel and nano-channel technology, which is applied in the field of preparing embedded micro-nano channels, can solve the problems of numerous instruments and complicated procedures, and achieve the effects of high-precision preparation features, high graphic resolution, and easy cycle control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

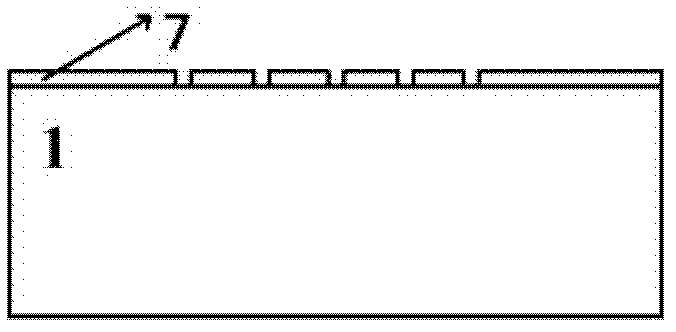

[0071] 1. Preparation of supporting sacrificial layer:

[0072] Design the shape, size, distribution, etc. of the required channels. According to the length of the required nanopore hole, width, height, shape, and distribution (can be a cross distribution) to design the required parameters of the nanostructure of the supporting sacrificial layer, the width and height of the nanostructure of the sacrificial layer are related to the size of the hole. Dimensions are related, and the exact relationship depends on the material and the parameters used to deposit the tungsten. The shape and distribution of the supporting sacrificial layer determine the shape and distribution of the nanochannels. The fabrication of the nanostructure of the supporting sacrificial layer can adopt the process of electron beam exposure-metal evaporation-dissolution to realize the metal nanostructure of the supporting sacrificial layer with specific position, characteristic size and specific distribution....

Embodiment 1

[0082] Formation of nanochannels in SiO based on ion beam assisted deposition of tungsten on nanowires 2 / Si substrate with metal nanowires as a supporting sacrificial layer to construct a three-dimensional nanochannel network. Specific steps are as follows:

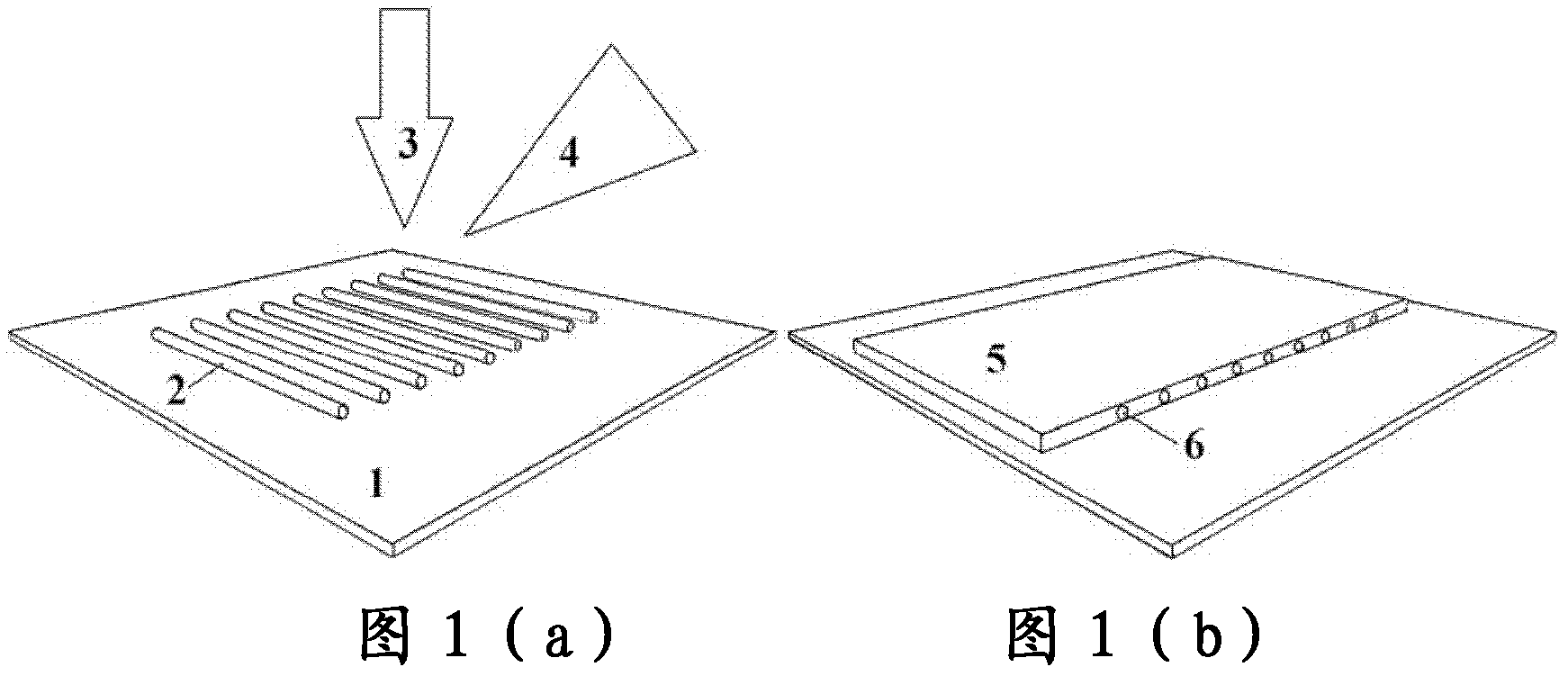

[0083] 1. Preparation of metal nanowire network

[0084] Since the electron beam exposure process can produce nanowires of any shape, the metal nanowire network can be produced by the electron beam exposure-metal deposition-elution process, including the following steps, as shown in Figure 2: (1) In the clean SiO 2 A layer of electron beam photoresist (PMMA4955%, 4000 rotations) was coated on the / Si substrate by spin-coating process. (2) Electron beam exposure is used to expose the required nanowire network lines on the photoresist, and at the same time, a cross-shaped mark for calibration is exploded around the pattern, and the exposed pattern is transferred to the photoresist by developing and fixing superior. (3)...

Embodiment 2

[0099] Based on the formation of nanochannels when tungsten is assisted by ion beam deposition on nanowires, a three-dimensional nanochannel network is constructed on a Si substrate with multi-walled carbon nanotubes as a supporting sacrificial layer. Specific steps are as follows:

[0100] 1. Preparation and dispersion of multi-walled carbon nanotubes

[0101] Multi-walled carbon nanotubes can be prepared by various methods such as arc discharge method, laser ablation method, chemical vapor deposition method (hydrocarbon gas pyrolysis method), solid phase pyrolysis method, glow discharge method and gas combustion method, etc. and polymerization synthesis. Soak the prepared carbon nanotubes in alcohol to make them uniformly dispersed on the substrate by ultrasonic. 2. Formation of nanochannels.

[0102] 2. Preparation of micro-nano channels

[0103] (1) Sample placement and fixation: The Si substrate is fixed on the sample holder with a horizontal surface from the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com