Maskless preparation device and method of a chalcogenide optical fiber grating

A technology for fiber gratings and preparation devices, which is applied to microlithography exposure equipment, photolithography exposure devices, cladding optical fibers, etc., and can solve the problem of long processing time, limited processing area and difficult number of pulses in the laser direct writing method. Control and other issues, to achieve good practical value and application prospects, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

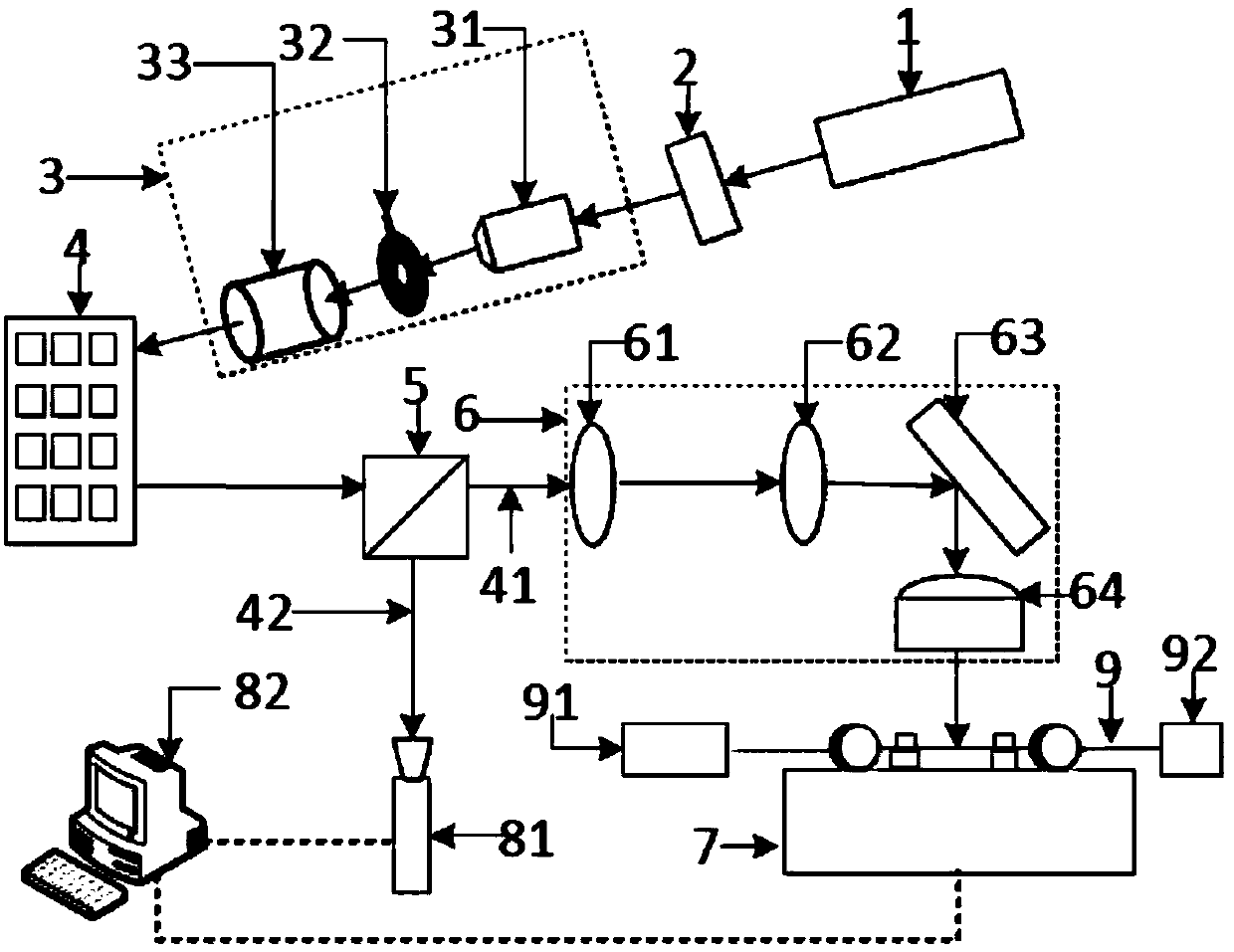

[0023] Embodiment 1: A maskless preparation device for chalcogenide fiber gratings, such as figure 1 As shown, it includes a laser light source 1, an attenuation plate 2, a laser light source collimating optical system 3, a digital micromirror device (ie DMD) 4, a beam splitter 5, an imaging optical system 6, a mobile working platform 7, a CCD 81 and a computer 82, A chalcogenide optical fiber 9 is placed on the mobile working platform 7. The laser light source 1 is an athermal femtosecond laser with a wavelength of 800 nm and a repetition rate of 1 kHz. The directions of the laser pulses emitted by the laser light source 1 are arranged sequentially, and the chip of the digital micromirror device 4 is loaded with the graphics of the preset target grating, and the laser pulses reflected by the digital micromirror device 4 are divided into two beams, that is, the first laser beam 41 And the second laser beam 42, the first laser beam 41 keeps the direction of reflection and conti...

Embodiment 2

[0035] Embodiment 2: A maskless preparation device of a chalcogenide fiber grating, such as figure 1 As shown, it includes laser light source 1, attenuation sheet 2, laser light source collimating optical system 3, digital micromirror device 4, beam splitter 5, imaging optical system 6, mobile working platform 7, CCD 81 and computer 82, mobile working platform 7 A chalcogenide optical fiber 9 is placed on it, the laser light source 1 is an athermal effect femtosecond laser with a wavelength of 800nm and a repetition rate of 1kHz, the attenuation plate 2, the laser light source collimating optical system 3 and the digital micromirror device 4 emit along the laser light source 1 The laser pulse direction of the digital micromirror device 4 is laid out sequentially, and the chip of the digital micromirror device 4 is loaded with the pattern of the preset target grating, and the laser pulse reflected by the digital micromirror device 4 is divided into two beams, that is, the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com