Method for directly writing metal micro-nano structure by ultraviolet laser interferometry etching

A technology of ultraviolet laser and micro-nano structure, applied in the direction of nano-structure manufacturing, laser welding equipment, metal processing equipment, etc., can solve the problems that limit the wide application of metal photonic crystals and practical technology development, complex preparation process, expensive preparation equipment, etc. , to achieve the effect of improving adhesion and firmness, good repeatability and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

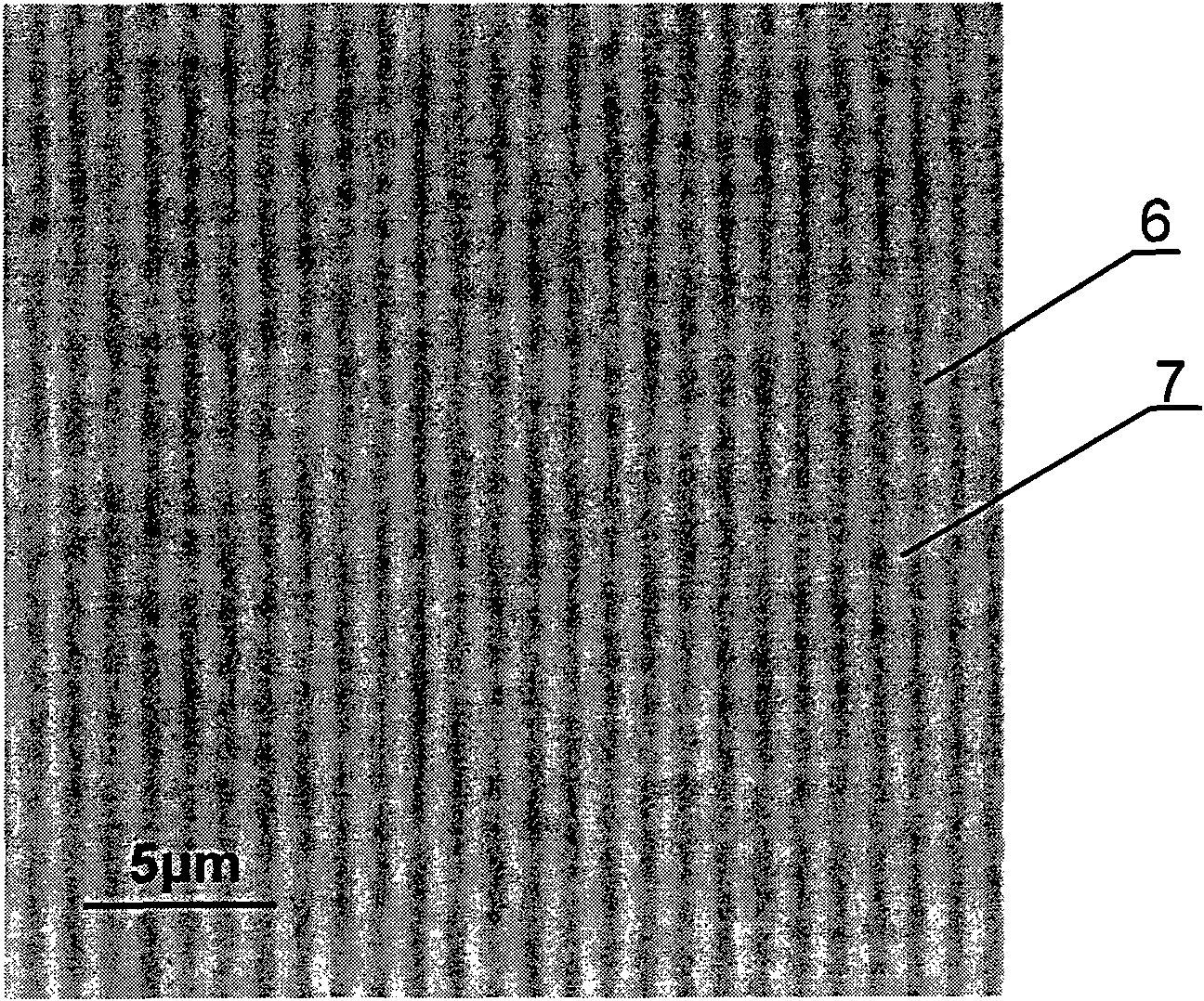

[0020] Example 1: Preparation of a one-dimensional gold nanowire photonic crystal structure.

[0021] 1) dissolving the chemically synthesized gold nanoparticles with an average diameter of 5nm in organic solvents such as toluene or xylene to make a gold nanoparticle colloid solution with a concentration of 100 mg / ml;

[0022] 2) Spin-coat the colloidal solution of gold nanoparticles on the glass substrate. The spin coating speed is 2000rpm, and the corresponding film thickness is about 200nm;

[0023] 3) The sample spin-coated with the gold nanoparticle colloidal film is placed on a heating plate, and heated at 250° C. for 25 seconds to obtain a sample with a uniform thickness and continuous gold film structure.

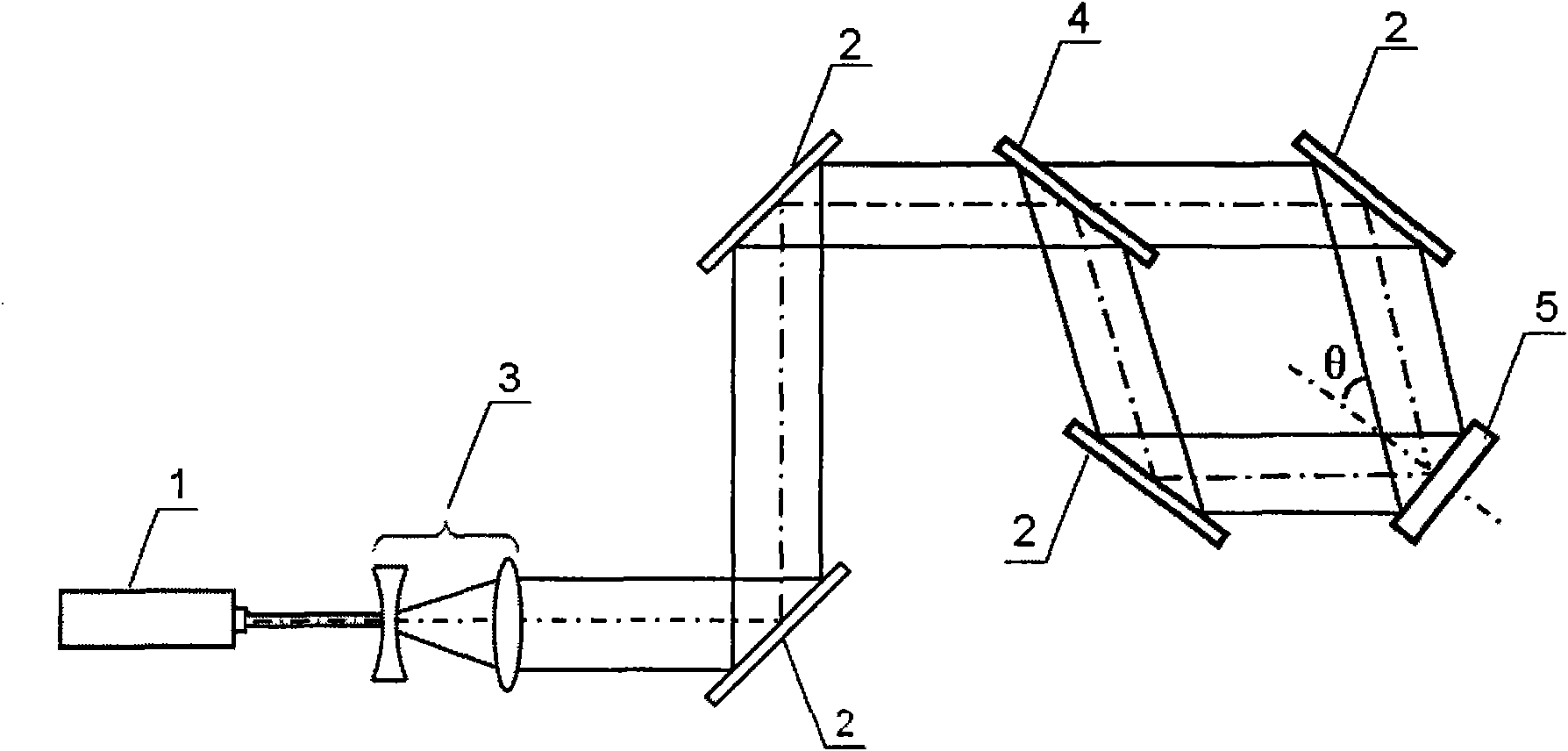

[0024] 4) Place the gold thin film sample prepared above in the interference light path, such as figure 1 As shown, the angle between the two beams is θ=7.8°. Using manual triggering to make the laser emit a laser pulse with an energy of 20mJ, a pulse width of 6n...

Embodiment 2

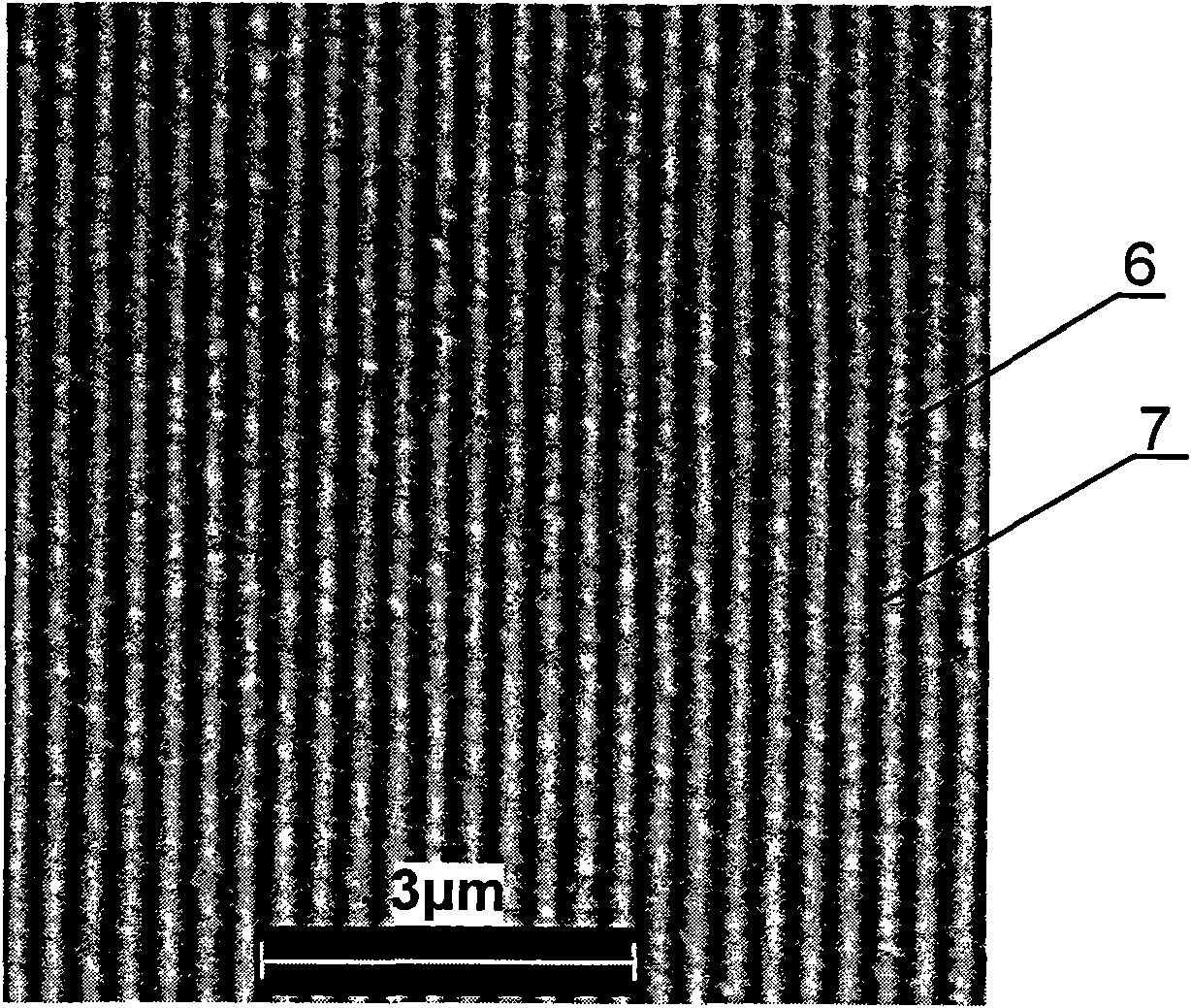

[0027] 1) dissolving chemically synthesized gold nanoparticles with an average diameter of 5nm in organic solvents such as toluene or xylene to make a gold nanoparticle colloid solution with a concentration of 100mg / ml;

[0028] 2) Spin-coat the colloidal solution of gold nanoparticles on the glass substrate. The spin coating speed is 2000rpm, and the corresponding film thickness is about 200nm;

[0029] 3) The sample spin-coated with the gold nanoparticle colloidal film is placed on a heating plate, and heated at 250° C. for 25 seconds to obtain a sample with a uniform thickness and continuous gold film structure.

[0030] 4) Place the gold thin film sample prepared above in the interference light path, such as figure 1 As shown, the angle between the two beams of light is θ=26.3°. Using manual triggering to make the laser emit a laser pulse with an energy of 20mJ, a pulse width of 6ns, and a wavelength of 266nm, a periodic one-dimensional metal grating structure can be etc...

Embodiment 3

[0032] Example 3: Preparation of two-dimensional gold nanowire photonic crystal structure

[0033] On the basis of the one-dimensional metal nano-grating preparation technology realized in Example 1, the sample is rotated 90° around its normal, and then the second exposure and ablation are performed to realize the preparation of a two-dimensional metal nano-grating structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com