Spherical denitration catalyst and preparation method thereof

A denitrification catalyst, spherical technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor fluidity and dispersion of catalyst powder, large energy consumption, and unfavorable coating. , to achieve the effect of shortening the preparation time, avoiding secondary pollution, and ensuring low-temperature catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

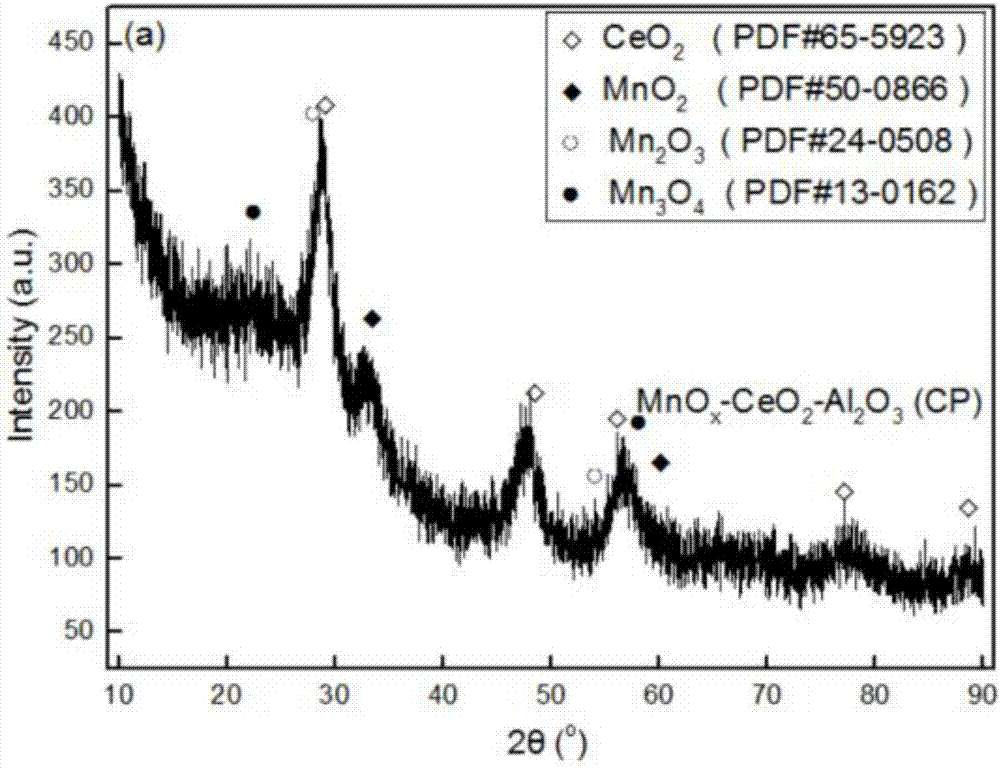

Embodiment 1

[0051] (1) Preparation of precursor salt solution:

[0052] a: 43.4g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 19.6g manganese acetate (Mn(CH 3 COO) 2 4H 2 O) and 75.0g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be dissolved in the deionized water of 50mL completely respectively, obtain cerium salt solution, manganese salt solution and aluminum salt solution; (the massfraction of cerium salt solution is 43.4÷93.4=46.5%, the massfraction of described manganese salt solution is 19.6% ÷69.6=28.2%, the mass fraction of the aluminum salt solution is 75÷125=60%, and the volume ratio of the cerium salt solution, the manganese salt solution and the aluminum salt solution is 1:1:1)

[0053] b: Mix the cerium salt solution, the manganese salt solution and the aluminum salt solution, heat to 30°C and stir for 1 hour to obtain the precursor salt solution; The molar amount of manganese element in the solution is 19.6÷245.08=0.08mol, the molar amount of aluminum element in the aluminum salt...

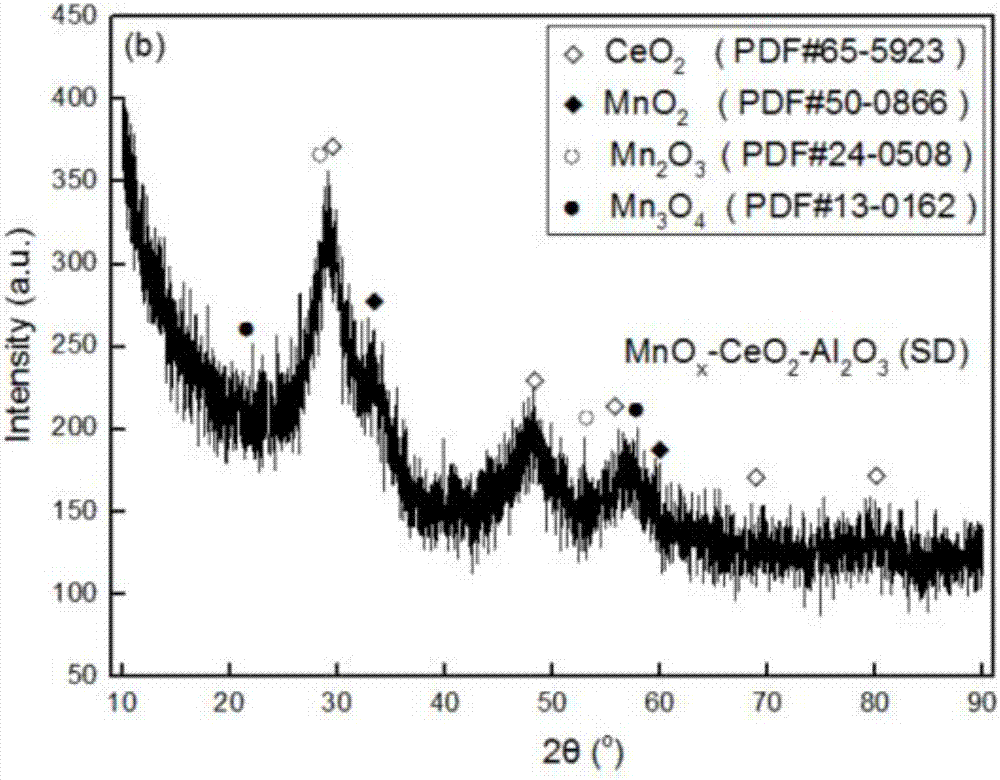

Embodiment 2

[0059] (1) Preparation of precursor salt solution:

[0060] a: 37.3g cerium chloride (CeCl 3 ·7H 2 O), 19.2 manganese chloride (MnCl 2 4H 2 O) and 75.0g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be dissolved in the deionized water of 50mL completely respectively, obtain cerium salt solution, manganese salt solution and aluminum salt solution; (the massfraction of cerium salt solution is 37.3÷87.3=42.7%, the massfraction of described manganese salt solution is 19.2% ÷69.2=27.7%, the mass fraction of said aluminum salt solution is 75÷125=60%, the volume ratio of cerium salt solution, manganese salt solution and aluminum salt solution is 1:1:1)

[0061] b: Mix the cerium salt solution, the manganese salt solution and the aluminum salt solution, heat to 40°C and stir for 1 hour to obtain the precursor salt solution; The molar amount of manganese in the solution is 19.2÷191.91=0.1mol, the molar amount of aluminum in the aluminum salt solution is 75÷375.13=0.2mol, and the molar r...

Embodiment 3

[0067] (1) Preparation of precursor salt solution:

[0068] a: 186.29g of cerium chloride (CeCl 3 ·7H 2 O) and 217.06g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) be completely dissolved in 600mL deionized water, 245.08g manganese nitrate (Mn(NO 3 ) 2 4H 2 O) was completely dissolved in 400mL deionized water, 375.13g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 241.43g aluminum chloride (AlCl 3 ·6H 2 O) be dissolved in the deionized water of 500mL completely, obtain cerium salt solution, manganese salt solution and aluminum salt solution; (the mass fraction of cerium salt solution is 403.35÷1003.35=40.2%, the mass fraction of described manganese salt solution is 245.08÷ 645.08=38%, the mass fraction of the aluminum salt solution is 616.56÷1116.56=55.22%, the volume ratio of the cerium salt solution, the manganese salt solution and the aluminum salt solution is 1.2:0.8:1)

[0069] b: Mix cerium salt solution, manganese salt solution and aluminum salt solution, heat to 30°C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com