Temperature sensor system and method for producing a temperature sensor system

A technology of temperature sensor and thermometer element, which is applied to the parts of thermometers, thermometers, and thermometers using electric/magnetic elements directly sensitive to heat, etc., which can solve problems such as delayed response time, and achieve precise shell size structure, high mechanical and chemical fastness, effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

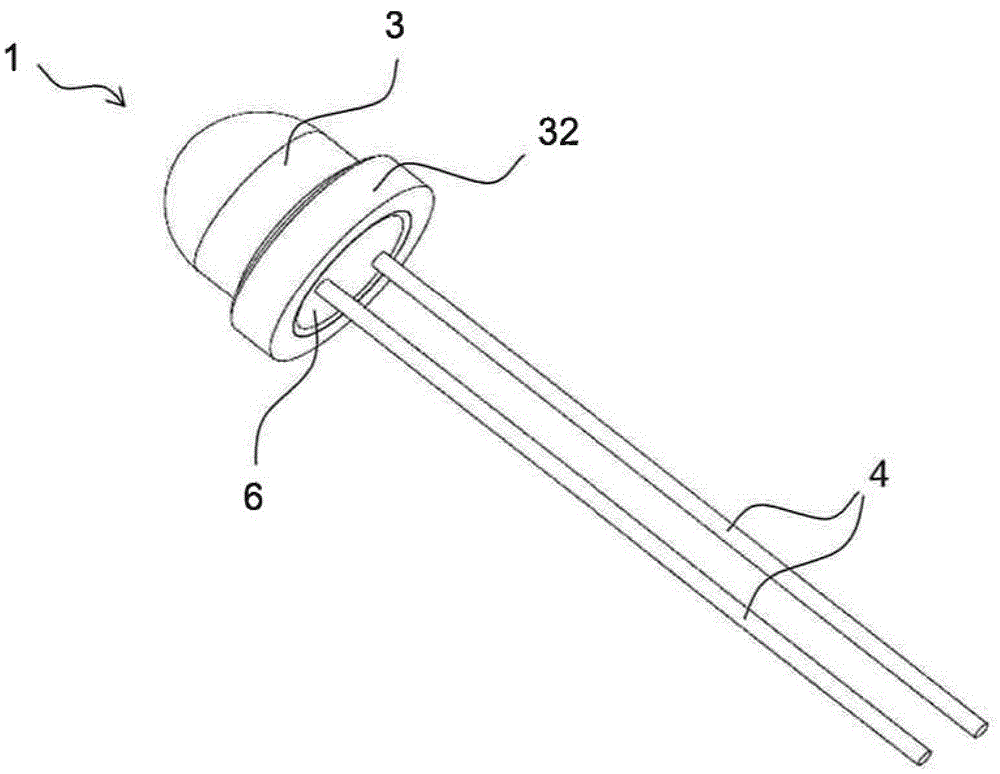

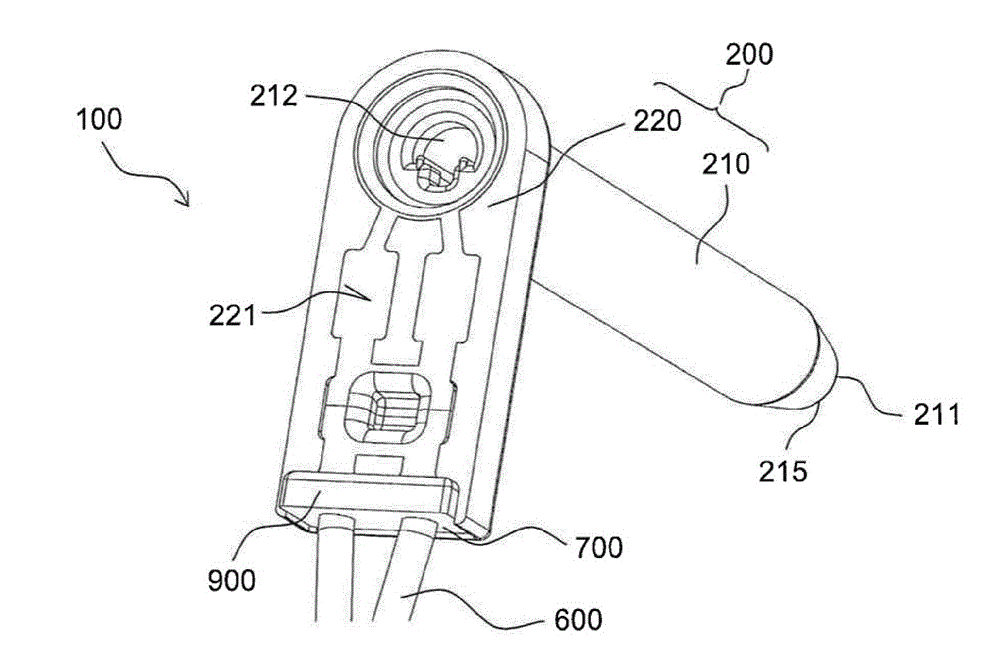

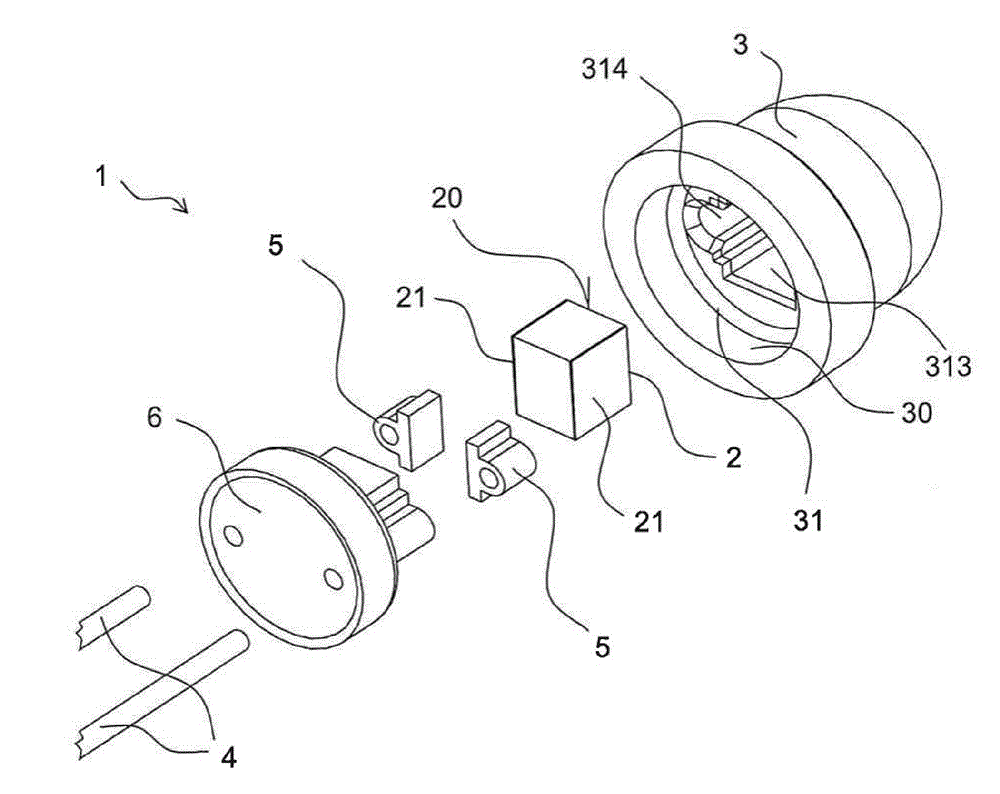

[0057] Figures 1 to 4 Various views of the temperature sensor system 100 described here are shown according to an exemplary embodiment. exist image 3 The temperature sensor system 100 in is shown without the second ceramic housing part 300 . Figure 5 show Figures 1 to 4 A cross-sectional view of the temperature sensor system 100 and the Figure 6 The medium temperature sensor system 100 is shown in exploded view. The description below also covers Figures 1 to 6 .

[0058] The temperature sensor system 100 has a first ceramic housing part 200 . The first ceramic housing part 200 has a sleeve-shaped lower part 210 with a first lower end 215 having a first opening 211 and a second upper end 216 having a second opening 212, and a second upper end 216 with the second upper end. The upper part 220 to which the part 216 is connected. The sleeve-shaped lower part 210 and the upper part 220 together form an "L-shaped" body, which is formed in one piece. The first ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com