Low-grade fluorite ore beneficiation process route assay method and process method

A process route and technology of fluorite ore, which is applied in the field of verification of low-grade fluorite ore beneficiation process route, can solve the problems of low-grade ore not being fully utilized, affecting the development of fluorite ore, and low output standards, etc., to achieve The effect of improving output stability, high grade and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

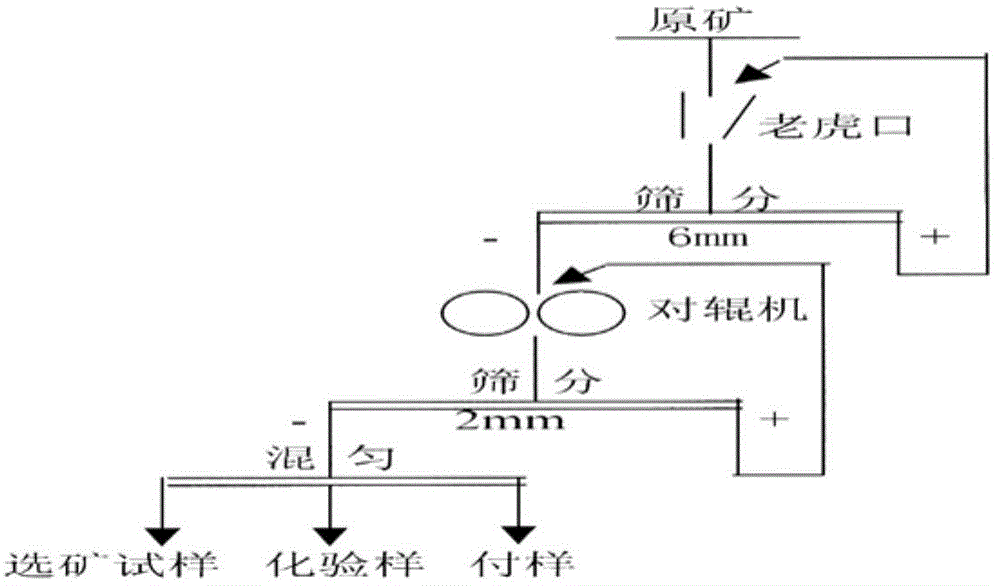

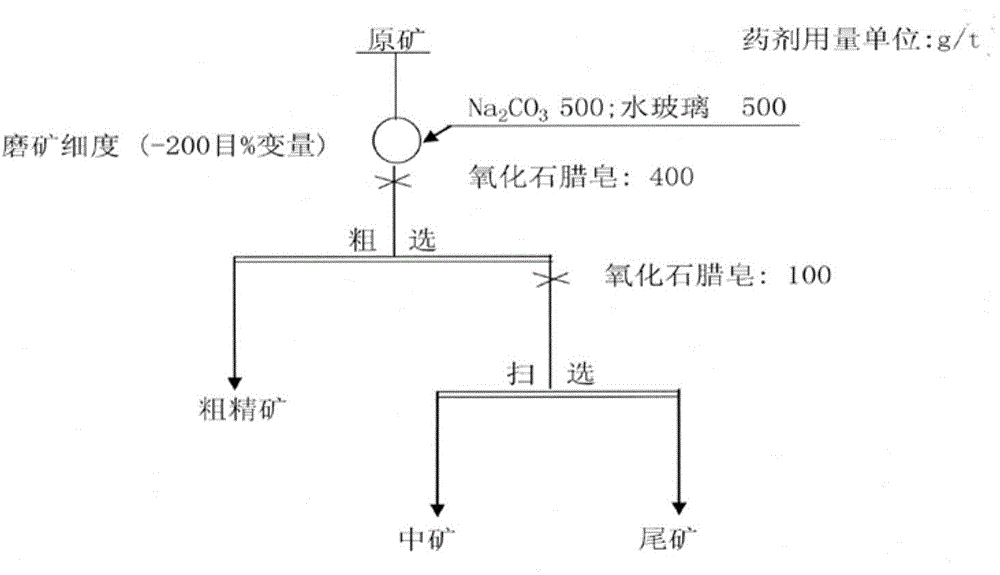

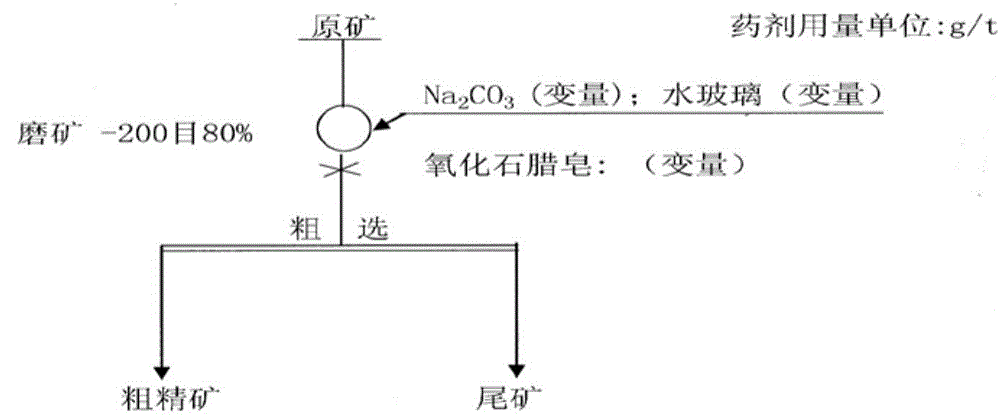

Method used

Image

Examples

Embodiment Construction

[0021] The embodiment of the present invention adopts the Jinzhukeng fluorite mine in Dehua County, Fujian Province, and the ore has a granular scale-like metamorphic structure. The ore composition is composed of ore minerals and gangue minerals. The ore minerals are fluorite ore, and the gangue minerals are secondary altered sericite, secondary quartz, andalusite, topaz, and corundum. According to the identification results under the thin-section microscope: the rock has not only suffered multiple periods of intense alteration and metasomatization, but also accompanied by obvious fluorite mineralization, the minerals in the original rock have been completely replaced by the secondary alteration minerals sericite and secondary quartz Instead of disappearing, the structure and structure of the original rock are completely changed and cannot be restored. The sericite is in the shape of fine scales, and the secondary quartz is in the shape of other shapes, with a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com