Preparation method of intelligent temperature-responsive superhydrophobic-hydrophilic wood

A temperature-responsive, super-hydrophobic technology, used in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of single super-hydrophobic performance of super-hydrophobic wood, which cannot meet the needs of daily life, and achieve low cost, short cycle, The effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

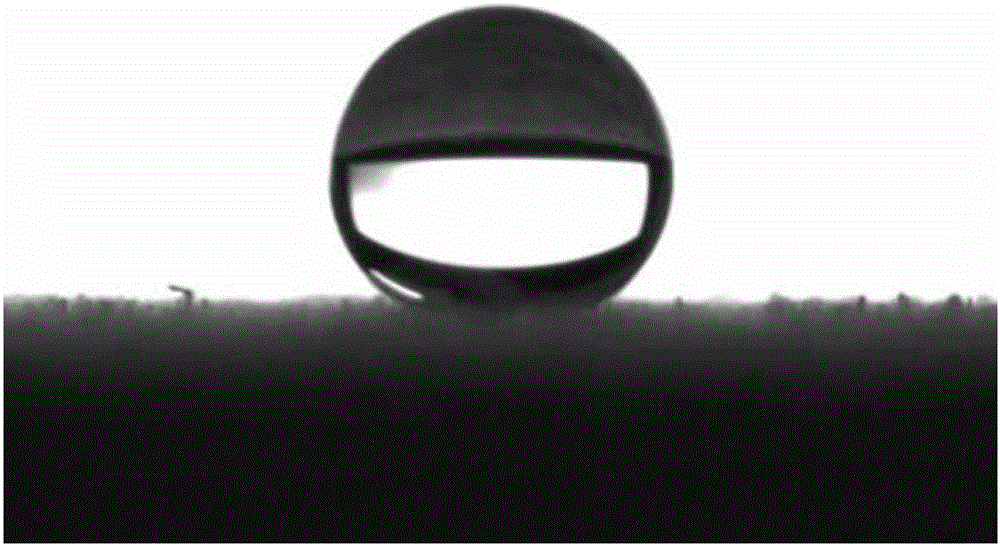

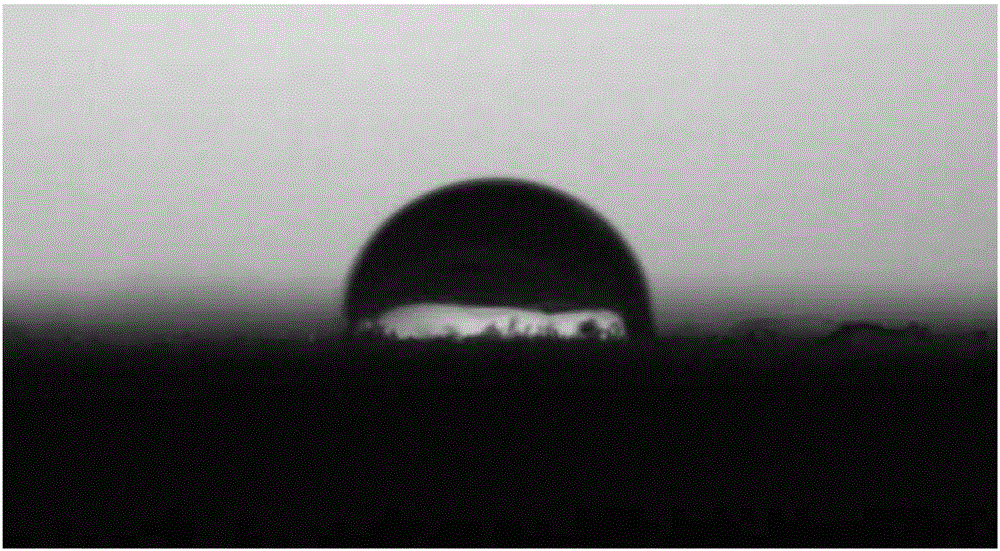

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of intelligent temperature-responsive super-hydrophobic-hydrophilic wood in this embodiment is carried out according to the following steps:

[0019] Step 1, the wood is ultrasonically cleaned with deionized water, acetone and absolute ethanol in sequence, and dried at 60°C for 12h to 24h;

[0020] Step 2. Weigh 0.2g of silicon dioxide with a particle size of 250nm and disperse it in 100mL of deionized water. Ultrasonic disperse for 0.5h at a working frequency of 50KHz, a power of 100%, and a temperature of 25°C, and then soak the wood in it 24h, then placed in a drying oven at 60°C for 24h;

[0021] dispersion

[0022] Step 3, prepare a mixed solution with methanol and chloroform at a volume ratio of 1:3, dissolve 0.025g of polycaprolactone in 5ml of the mixed solution, and then evenly drop-coat it on the horizontal surface of the wood treated in step 2 Place the cut surface in a vacuum drying oven, vacuumize to -0.8kPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com