A kind of preparation method of moisture-curing polyurethane hot-melt adhesive for textile composite

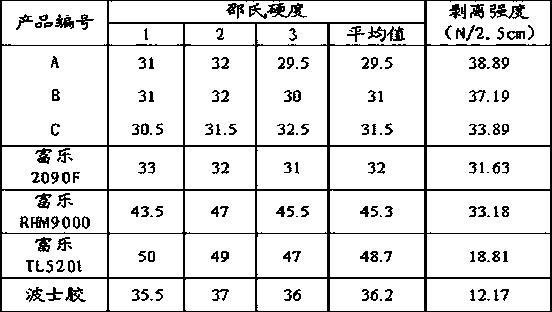

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of softness reduction, reinforcement, softness of soft fabrics, etc., to achieve reduction Shore hardness, softness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of moisture-cured polyurethane hot-melt adhesive for textile compounding, the steps are as follows:

[0035] (1) Stir and mix 40 parts of polyethylene glycol phthalate diol (molecular weight 2000), 25 parts of sebacic acid polyester polyol, 12.5 parts of adipic acid polyester polyol and 0.05 part of antioxidant , heated up to 120-130°C, and dehydrated for 2 hours at a vacuum degree of less than 100Pa;

[0036] (2) Cool down to 75-95°C, add 21.4 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.5 parts of stannous octoate, stir, and under the conditions of vacuum degree less than 100Pa and reaction temperature of 85-90°C Reaction 70min;

[0037] (3) Add 0.5 parts of 1,4-butanediol, and continue to react for 50 minutes at a vacuum degree of less than 100Pa and a temperature of 85-90°C;

[0038] (4) Cool down to 70-80°C, add 0.5 parts of γ-methacryloxypropyltrimethoxysilane, and continue to react for 1 hour at a vacuum degree of less than 100Pa and...

Embodiment 2

[0043] A preparation method of moisture-cured polyurethane hot-melt adhesive for textile compounding, the steps are as follows:

[0044] (1) Stir and mix 35 parts of polytrimethylene phthalate diol (molecular weight: 1000), 33.1 parts of sebacic acid polyester polyol, 16.6 parts of adipic acid polyester polyol and 0.05 part of antioxidant, and heat up To 120-130°C, dehydration for 2 hours under vacuum less than 100Pa;

[0045] (2) Cool down to 75-95°C, add 14.3 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.5 parts of stannous octoate, stir, and under the conditions of vacuum degree less than 100Pa and reaction temperature of 85-90°C Reaction 70min;

[0046](3) Add 0.5 parts of 1,4-butanediol, and continue to react for 50 minutes at a vacuum degree of less than 100Pa and a temperature of 85-90°C;

[0047] (4) Cool down to 70-80°C, add 2 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, and continue the reaction for 1 hour at a vacuum degree of less than 100Pa and a reac...

Embodiment 3

[0052] A preparation method of moisture-cured polyurethane hot-melt adhesive for textile compounding, the steps are as follows:

[0053] (1) Stir and mix 30 parts of polytrimethylene phthalate diol (molecular weight: 1000), 30.5 parts of sebacic acid polyester polyol, 15.7 parts of adipic acid polyester polyol and 0.05 part of antioxidant, and heat up To 120-130°C, dehydration for 2 hours under vacuum less than 100Pa;

[0054] (2) Cool down to 75-95°C, add 22.7 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.5 parts of stannous octoate, stir, and under the conditions of vacuum degree less than 100Pa and reaction temperature of 85-90°C Reaction 70min;

[0055] (3) Add 0.5 parts of 1,4-butanediol, and continue to react for 50 minutes at a vacuum degree of less than 100Pa and a temperature of 85-90°C;

[0056] (4) Cool down to 70-80°C, add 1 part of γ-aminopropyltriethoxysilane, and continue to react for 1h at a vacuum degree of less than 100Pa and a reaction temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com