Novel Wafer Bonding device

A new type of equipment technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large consumption of graphite materials, damaged blocks of graphite parts, and high equipment failure rate, achieving fast heating speed and easy maintenance. , the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

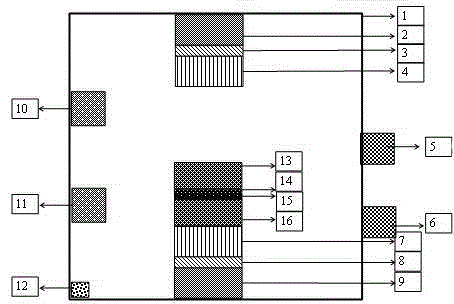

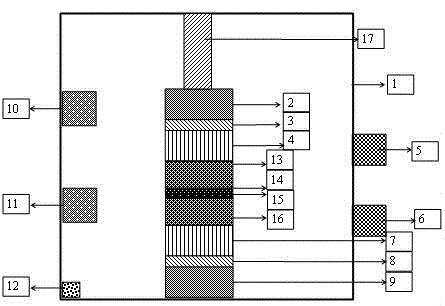

[0017] Such as figure 1 As shown, the new Wafer Bonding equipment includes a vacuum chamber 1. A vacuum generator 12 is arranged inside the vacuum chamber 1. An upper pressure control system and a lower pressure control system are respectively arranged on the upper and lower walls of the vacuum chamber 1. The pressure control system is movably connected with the front wall of the vacuum chamber 1 through the telescopic connection shaft 17, and the telescopic connection shaft 17 drives the upper pressure control system to rise and fall. The upper pressure control system consists of the upper pressure cylinder 2, the upper heat insulation The layer 3 and the upper heater 4 are composed, and the lower pressure control system is composed of the lower pressure cylinder 9, the lower heat insulation layer 8 and the lower heater 7.

[0018] The outer wall of the vacuum chamber 1 is provided with an upper microwave generator 5 and a lower microwave generator 6 in sequence, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com