Monolithic macro-channel heat sink for semiconductor laser and semiconductor laser

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of no technical solution or inspiration, uneven heat dissipation of laser chips, scrapped laser stacks, etc., and achieve better and uniform heat dissipation effect. , the effect of increased size, reduced risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

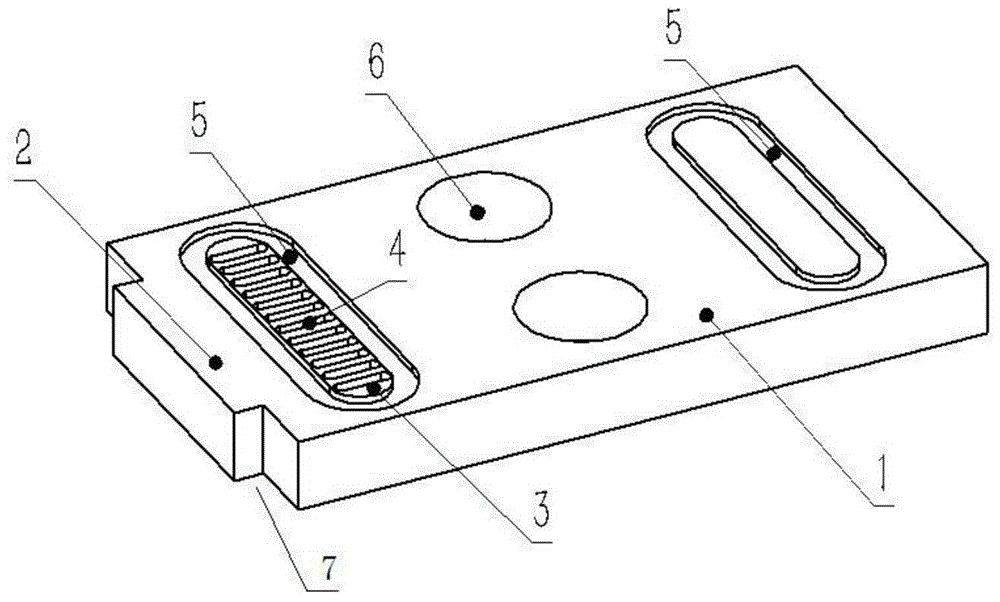

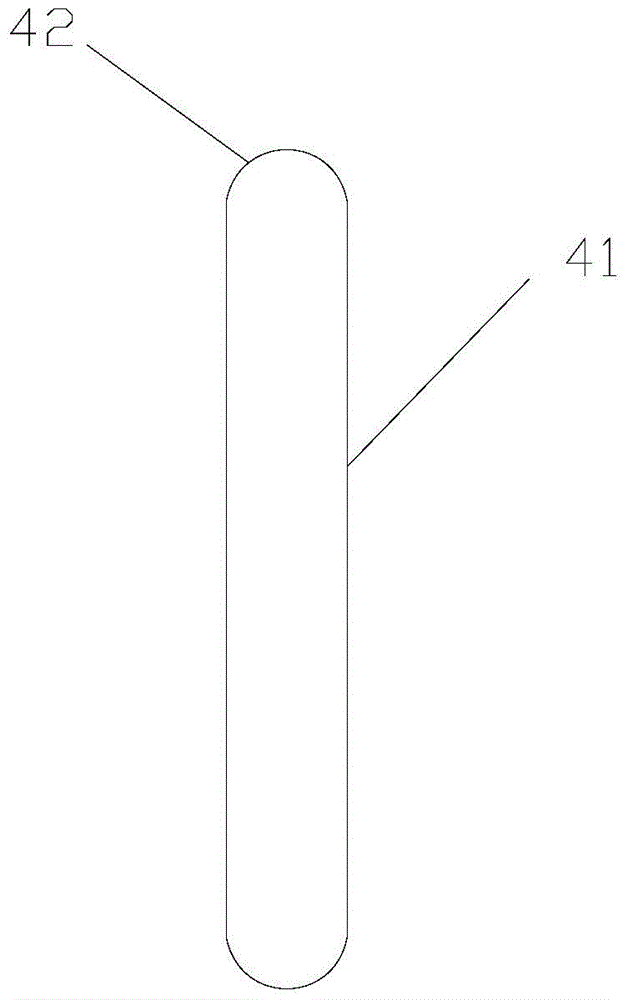

[0029] Please refer to figure 1 , 2 , a semiconductor laser monolithic macro-channel heat sink provided by the present invention mainly includes a heat sink body 1, the heat sink body 1 is a sheet structure, and its surface shape is rectangular, on one side of the heat sink body 1 (for For convenience of description, this surface is defined as "upper surface", and the opposite side is "lower surface"). There is a chip mounting area 2 on one end of the heat sink body 1. On both sides of the chip mounting area 2, there are The notch 7 makes the chip mounting area 2 form an outwardly protruding structure relative to other parts of the heat sink body 1. A water cooling area 3 is provided near the chip mounting area 2. Its shape is "racetrack type", and it can also be Rectangular or other shapes, the length of the water cooling area 3 is longer than the length of the chip mounting area 2, so that the heat dissipation area is larger and more uniform. It can also provide working sp...

Embodiment 2

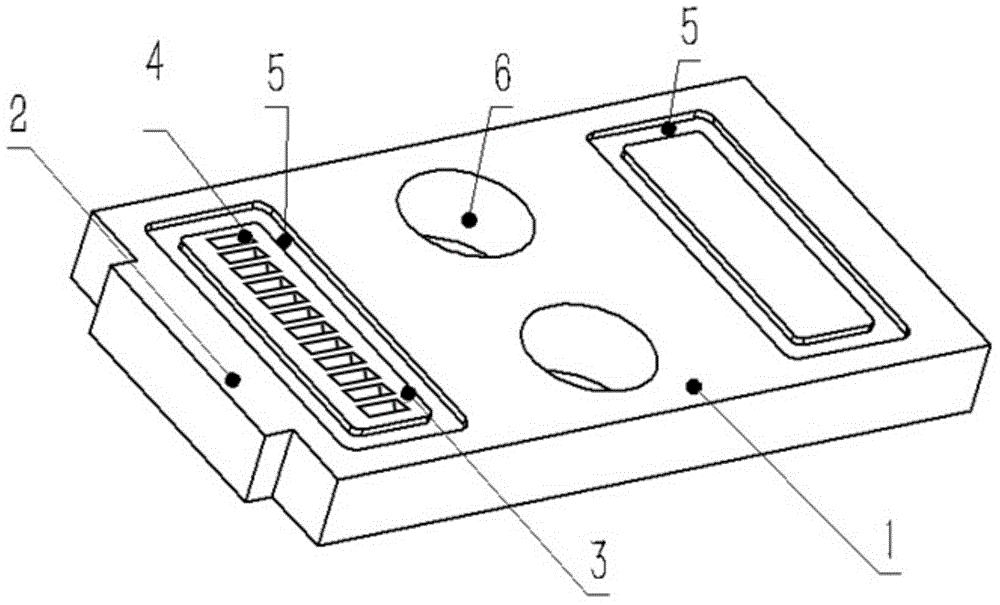

[0039] Such as image 3 , 4 As shown, the difference between the semiconductor laser monolithic macro-channel heat sink provided in this embodiment and Embodiment 1 is that the connection end 42 of the grid hole 4 is linear, that is, it forms a rectangular shape after being combined with two parallel side walls 41 The hole type, its size also can make adaptive adjustment within the scope that gives in embodiment 1. The technical concept of this hole pattern and its arrangement is basically the same as the "racetrack" hole pattern in Embodiment 1, and it also has the characteristics of regular, uniform, end flush and equidistant from the chip mounting area 2. Play an excellent heat dissipation effect. In addition, the shape of the sealing groove 5 is also a rectangle (of course, the raceway shape in Embodiment 1 can also be used).

Embodiment 3

[0041] Please also refer to Figure 5 , this embodiment provides a semiconductor laser that includes a semiconductor laser monolithic macro-channel heat sink in Embodiment 1 or Embodiment 2. The core components in the semiconductor laser include bottom water blocks that are arranged sequentially from bottom to top 11. The lower insulating sheet 12, the positive electrode sheet 13, the semiconductor laser module 14, the negative electrode sheet 15, the upper insulating sheet 16, and the upper water block 17; the semiconductor laser module 14 is formed by stacking a plurality of semiconductor laser units, and the semiconductor laser The module 14 is provided with a liquid cooling channel; the semiconductor laser unit includes a laser chip, a semiconductor laser monolithic macro-channel heat sink, an insulating layer and a negative connection plate, and the semiconductor laser monolithic macro-channel heat sink is Embodiment 1 or embodiment The heat sink in 2, the grid on the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com