Cooking method adopting hot wind to assist in moisture removal

A technology for cooking vegetables and hot air is applied in the field of cooking vegetables that uses hot air to assist to quickly remove water vapor, and can solve problems such as poor taste and heavy moisture in cooking containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

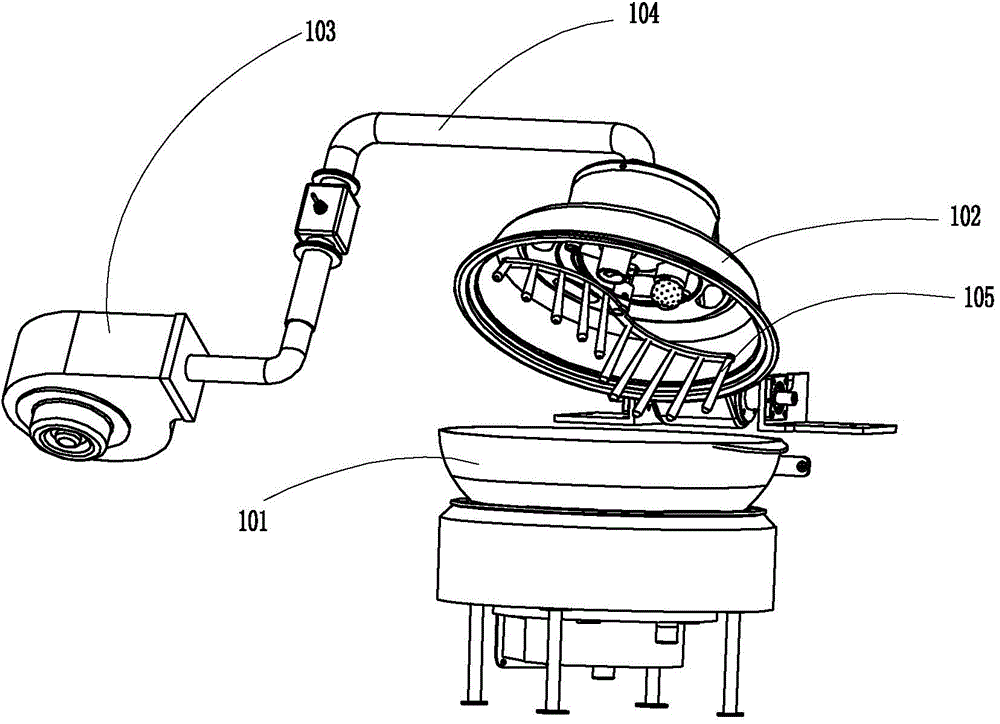

[0084] In this embodiment, the cooking method using hot air to quickly remove water vapor is used. The main heating system and the auxiliary heating system are used for heating. The heat sources of the main heating system and the auxiliary heating system are different; wherein the auxiliary heating system includes a hot air heating system. , the hot air heating system supplies air in sections instead of the whole process; the method includes the following steps:

[0085] (1) Start the cooking equipment and switch to the cooking program;

[0086] (2) Activate the main heating system to heat the pot body under the pot;

[0087] (3) Put cooking materials into the pot;

[0088] (4) During the cooking process, the hot air heating system is activated once or more in stages, and hot air is introduced into the pot from above the pot to directly heat the cooking materials in the pot; In the stage of water vapor, the hot air heating system is activated, or the heating power of the hot...

Embodiment 2

[0094] The difference between this embodiment and embodiment 1 is:

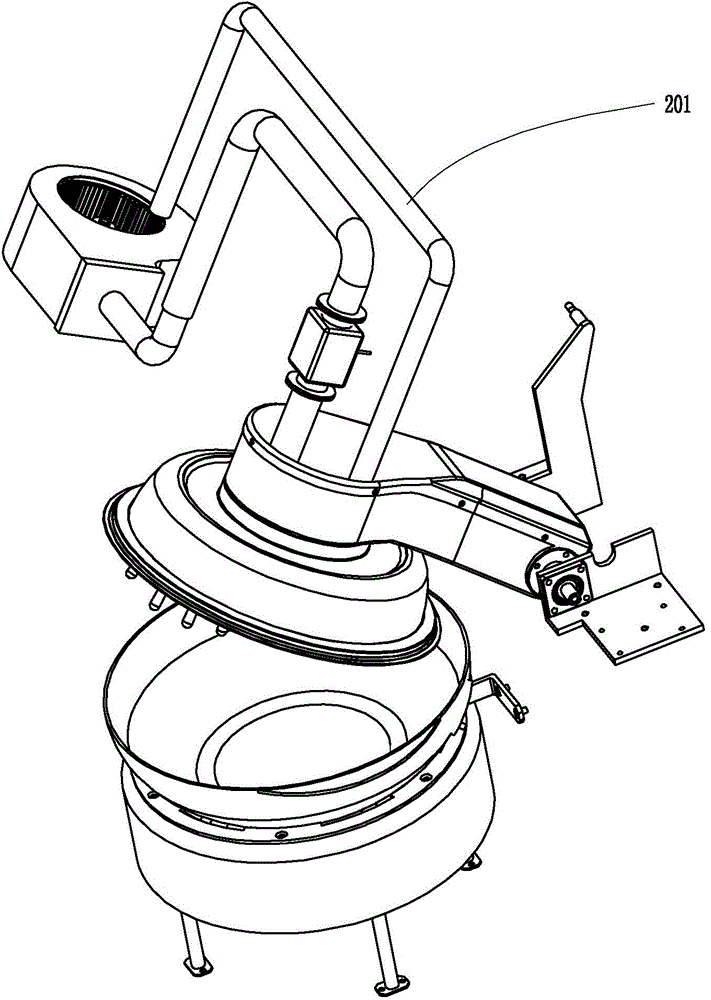

[0095] 1. If figure 2 As shown, the pot cover is provided with an exhaust pipe 201, and the end of the exhaust pipe 201 is connected to the air supply duct to realize the recycling of air. The exhaust pipe is provided with an inner filter assembly for removing water vapor and smoke.

[0096] 2. The auxiliary heating system further includes a radiation heating system (infrared heating system). The infrared heating system includes an infrared heating tube. The infrared heating tube includes an inner heating tube and an outer heating tube. The upper surface of the cooking material inside is directly heated, and at the same time, the lower surface of the cooking material is indirectly heated by directly heating the pot body; the outer heating pipe is arranged on the outside of the wok and surrounds the wok, and does not interfere with the gas heating system .

Embodiment 3

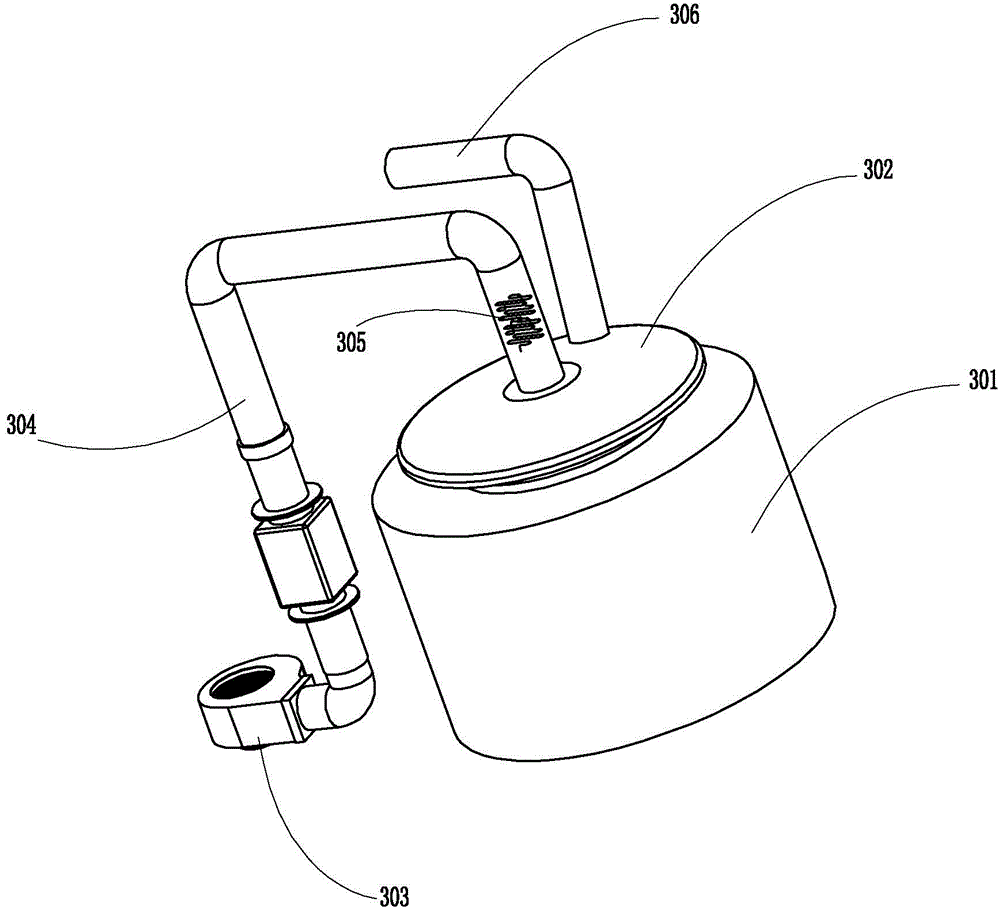

[0098] Such as image 3 As shown, the automatic cooking device in this embodiment is a covered drum device, which includes a bracket (not shown in the figure), a drum 301, and a pot heating system.

[0099] The drum 301 is arranged on the support, and it is provided with a pot cover 302 that can be opened during cooking.

[0100] The pot heating system includes a main heating system and an auxiliary heating system, wherein the main heating system is a gas heating system, which directly heats the pot body of the pot; the auxiliary heating system is a hot air heating system, and the hot air heating system includes a blast device 303, air supply duct 304 and heat source (heating pipe 305); the blower device 303 generates an airflow, which is conveyed by the air supply duct 304, and after being heated by the heat source, blows into the drum 301 to directly heat the cooking material. The heating pipe 305 is located in the air supply duct 304, and the end of the air supply duct 304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com