Preparation method of high-activity porous LaMnO3+delta electrocatalyst

An electrocatalyst and high-activity technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing raw material costs, impurities in products, and low catalytic activity and other problems, to achieve the effect of simple preparation method, simple equipment and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

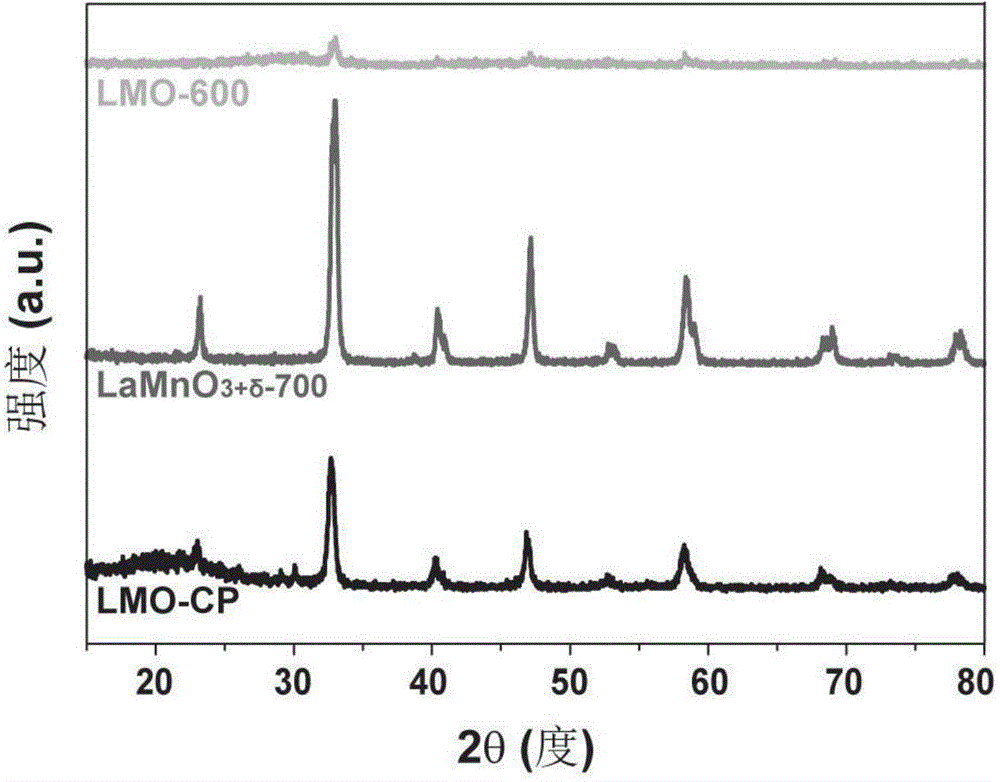

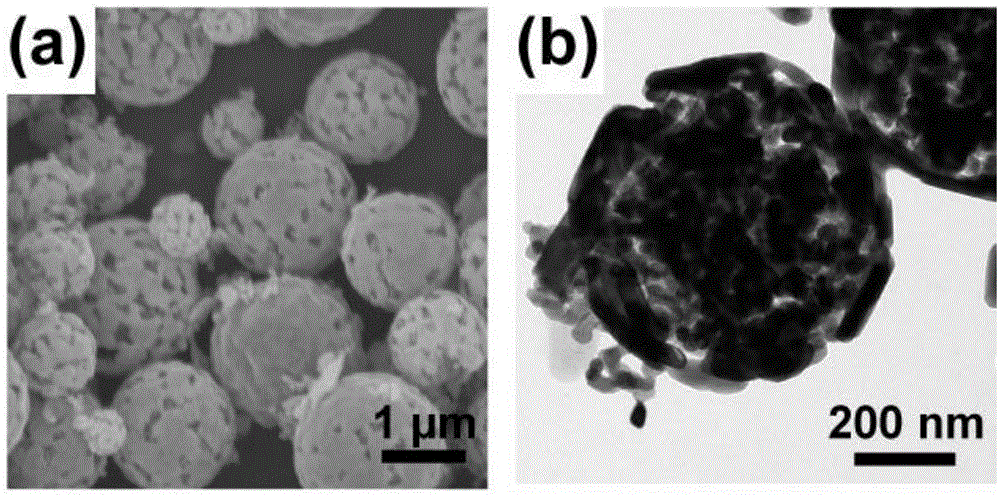

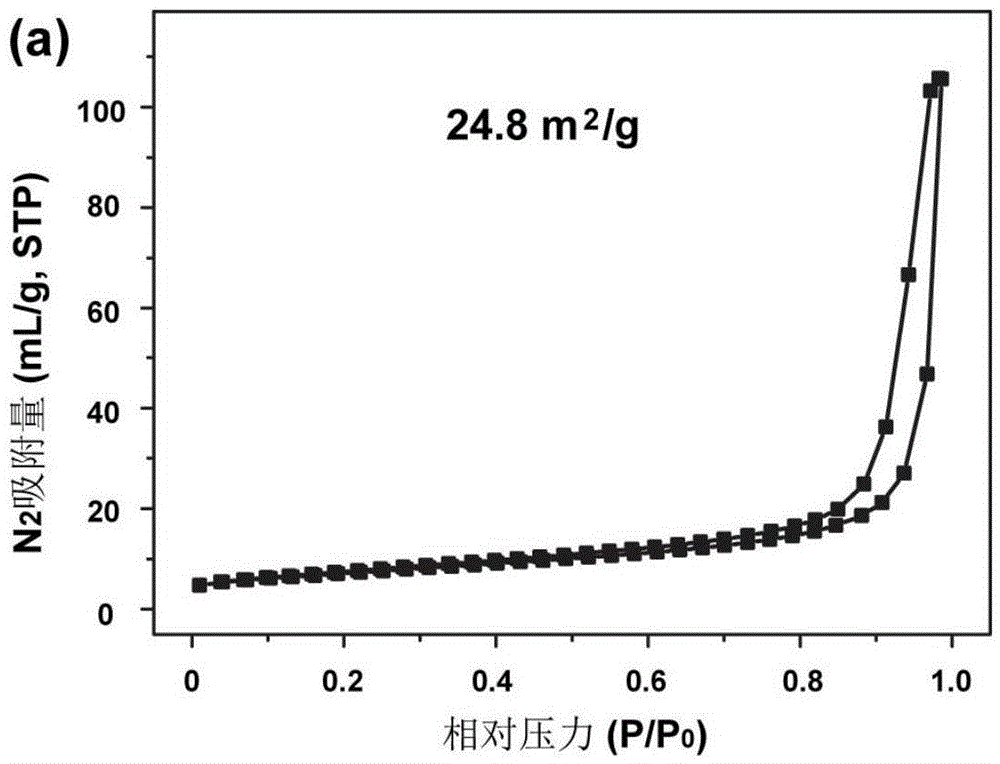

[0038] A highly active porous LaMnO 3+δ The preparation method of electrocatalyst comprises the following steps:

[0039] Weigh 0.43g La(NO 3 ) 3 ·6H 2 O, mass percent is the Mn(NO of 0.36g of 50% 3 ) 2 solution and 0.25g P123 (triblock copolymer (EO) 20 -(PO) 70 -(EO) 20 abbreviation), dissolved in 20mL ethanol, and transferred to an ultrasonic nebulizer for atomization. Under the action of the vacuum pump, the atomized small droplets enter the glass tube preheated to 480 ° C, and the powder is collected at the other end by a filter device. The powder was calcined in air at 600 °C for 4 hours to obtain porous LaMnO 3+δ electrocatalyst.

Embodiment 2

[0041] A highly active porous LaMnO 3+δThe preparation method of electrocatalyst comprises the following steps:

[0042] Weigh 0.43g La(NO 3 ) 3 ·6H 2 O, mass percent is the Mn(NO of 0.36g of 50% 3 ) 2 solution and 0.25g P123 (triblock copolymer (EO) 20 -(PO) 70 -(EO) 20 abbreviation), dissolved in 20mL ethanol, and transferred to an ultrasonic nebulizer for atomization. Under the action of the vacuum pump, the atomized small droplets enter the glass tube preheated to 480 ° C, and the powder is collected at the other end by a filter device. The powder was calcined in air at 700 °C for 4 hours to obtain porous LaMnO 3+δ electrocatalyst.

Embodiment 3

[0044] A highly active porous LaMnO 3+δ The preparation method of electrocatalyst comprises the following steps:

[0045] Weigh 0.43g La(NO 3 ) 3 ·6H 2 O, mass percent is the Mn(NO of 0.36g of 50% 3 ) 2 solution and 0.25g P123 (triblock copolymer (EO) 20 -(PO) 70 -(EO) 20 Abbreviation), dissolved in 40mL ethanol, and transferred to an ultrasonic nebulizer for atomization. Under the action of the vacuum pump, the atomized small droplets enter the glass tube preheated to 480 ° C, and the powder is collected at the other end by a filter device. The powder was calcined in air at 700 °C for 4 hours to obtain porous LaMnO 3+δ electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com