Magnetic multistage nuclear @ shell structure nano-palladium catalyst and preparation method thereof

A technology of core-shell structure and magnetic nanoparticles, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of magnetic nanoparticles

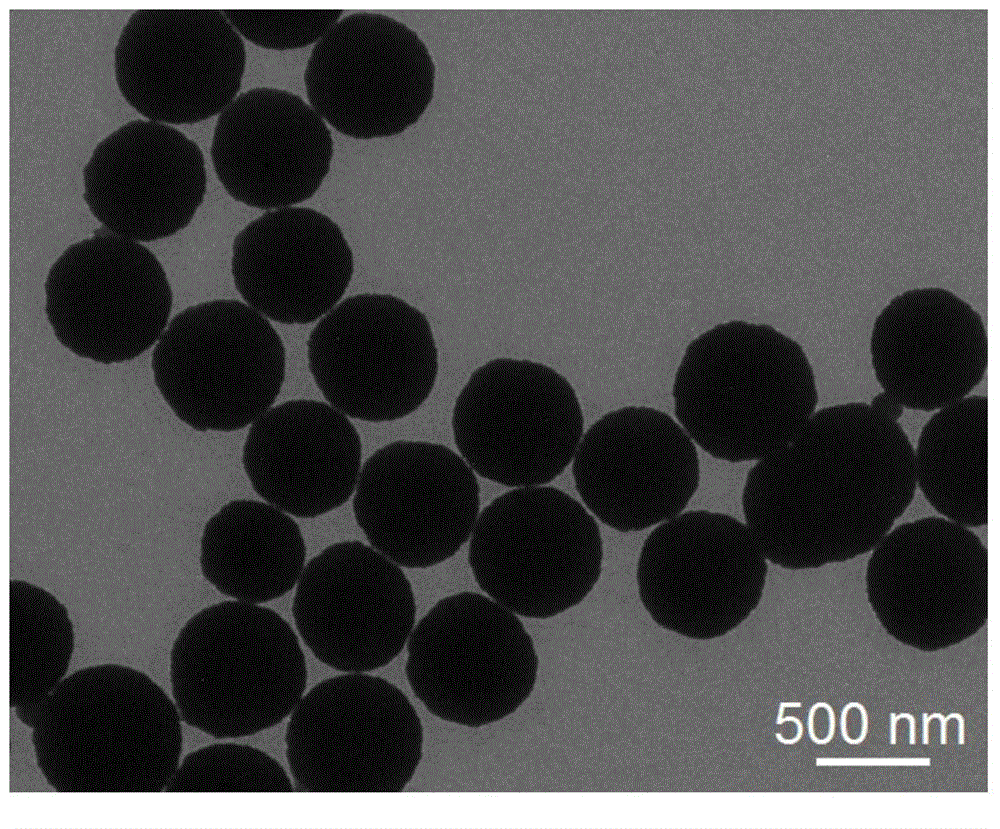

[0040] Take 2.16g FeCl 3 ·6H 2 O was dissolved in 80 mL of ethylene glycol in a water bath at 40 °C to obtain a homogeneous and stable solution; 5.76 g of NaAc·3H 2 O, stir slowly until it is completely dissolved, avoiding the generation of air bubbles; transfer to a 100mL polytetrafluoroethylene-lined self-generating pressure bomb, and react at 200°C for 8h. Cool naturally to room temperature, magnetically separate with NdFeB permanent magnets, wash with ethanol for 5 times, then wash with deionized water until neutral, and dry at 60°C for 24 hours to obtain black powdery magnetic nanoparticles, denoted as Fe 3 o 4 . Transmission electron microscopy results (attached figure 1 ) shows that the resulting Fe 3 o 4 The magnetic nanoparticles are spherical particles with a particle diameter of about 400nm; the test results of the magnetic intensity of the vibrating sample show that it has typical superparamagnetism, and the...

Embodiment 2

[0046] (1) Preparation of magnetic nanoparticles

[0047] Take 2.16g FeCl 3 ·6H 2 O was dissolved in 80 mL of ethylene glycol in a water bath at 40 °C to obtain a homogeneous and stable solution; 5.76 g of NaAc·3H 2 O, stir slowly until it is completely dissolved, avoiding the generation of air bubbles; transfer to a 100mL polytetrafluoroethylene-lined self-generating pressure bomb, and react at 200°C for 8h. Cool naturally to room temperature, magnetically separate with NdFeB permanent magnets, wash with ethanol for 5 times, then wash with deionized water until neutral, and dry at 60°C for 24 hours to obtain black powdery magnetic nanoparticles, denoted as Fe 3 o 4 , its size and magnetic properties are the same as in Example 1.

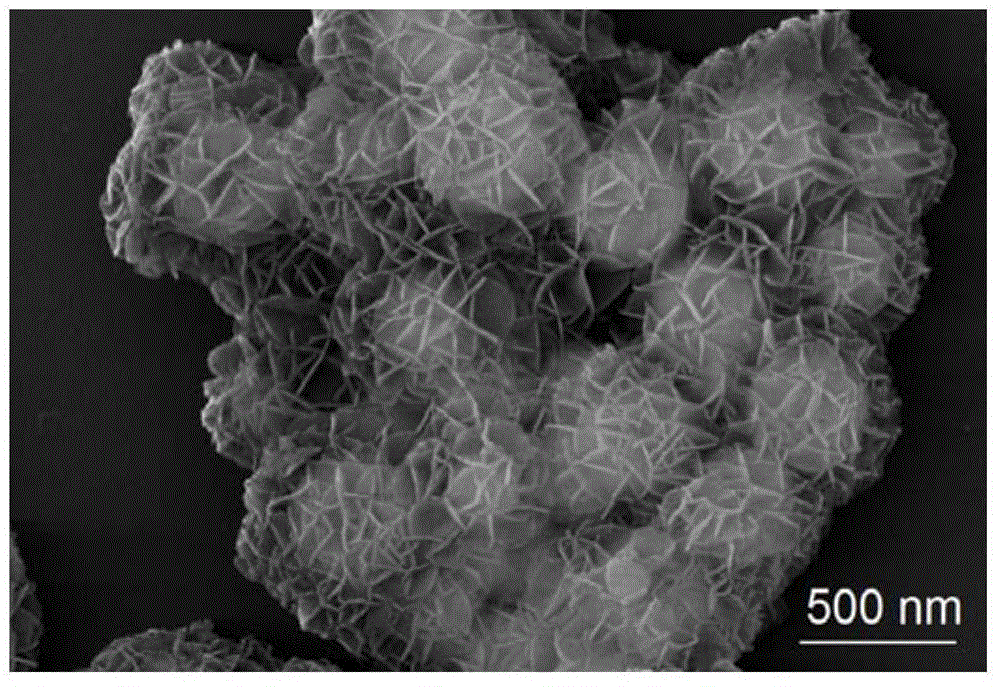

[0048] (2) Preparation of magnetic multi-level core-shell structure hydrotalcite carrier

[0049] Weigh 1.042g Fe 3 o 4The nanoparticles were ultrasonically dispersed in 100 mL of water for 20 min. 2.622g Co(NO 3 ) 2 ·6H 2 O and 1.125g Al...

Embodiment 3

[0053] (1) Preparation of magnetic nanoparticles

[0054] Take 2.16g FeCl 3 ·6H 2 O was dissolved in 80 mL of ethylene glycol in a water bath at 40 °C to obtain a homogeneous and stable solution; 5.76 g of NaAc·3H 2 O, stir slowly until it is completely dissolved, avoiding the generation of air bubbles; transfer to a 100mL polytetrafluoroethylene-lined self-generating pressure bomb, and react at 200°C for 8h. Cool naturally to room temperature, magnetically separate with NdFeB permanent magnets, wash with ethanol for 5 times, then wash with deionized water until neutral, and dry at 60°C for 24 hours to obtain black powdery magnetic nanoparticles, denoted as Fe 3 o 4 , its size and magnetic properties are the same as in Example 1.

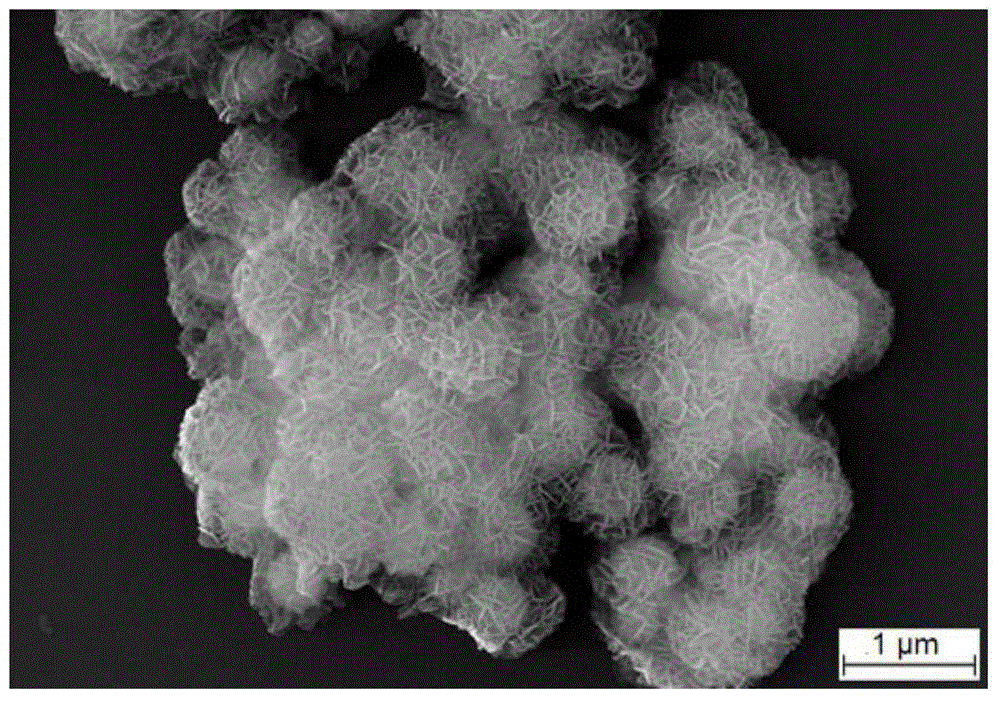

[0055] (2) Preparation of magnetic multi-level core-shell structure hydrotalcite carrier

[0056] Weigh 1.042g Fe 3 o 4 The nanoparticles were ultrasonically dispersed in 100 mL of water for 20 min. 2.620g Ni(NO 3 ) 2 ·6H 2 O and 1.125g A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com