Lithium ion battery silver, cobalt and nickel doped lithium manganate positive electrode material and preparation method thereof

A lithium ion battery, lithium heteromanganate technology, applied in battery electrodes, chemical instruments and methods, secondary batteries, etc., can solve problems such as rate performance, poor cycle performance, high reaction energy consumption, and poor consistency of positive electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

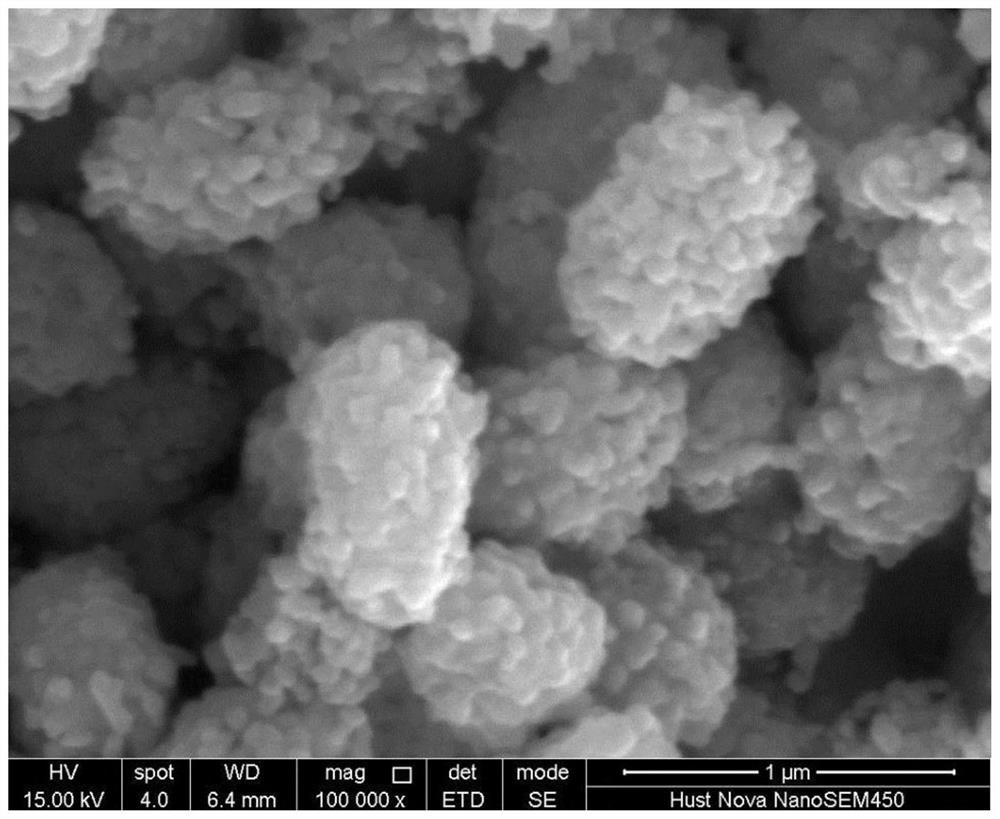

Embodiment 1

[0054] A lithium ion battery silver, cobalt and nickel doped lithium manganate positive electrode material, the specific steps of its preparation are:

[0055] A. Mix, grind or ball mill 0.8 moles of manganese sulfate, 0.05 moles of cobalt acetate, 0.15 moles of nickel nitrate, 0.51 moles of LiOH, 0.01 moles of silver fluoride, and 1.1 moles of potassium peroxodisulfate to form a uniform reaction mixture, and transfer the mixture to a polymer In a stainless steel reactor lined with tetrafluoroethylene;

[0056] B, stirring, in 20g surfactant CTAB, add 250mL distilled water, 100mL surfactant auxiliary isoamyl alcohol, 150mL cyclohexane successively, make transparent or translucent microemulsion;

[0057] C. The microemulsion of step B is added to the reactor of step A, mixed evenly, sealed, placed in an oven at 95 ° C for 36 hours, and cooled;

[0058] D, take out the mixture after C step reaction, suction filter, filter solid with 500mL 95wt% alcohol washing once, then wash w...

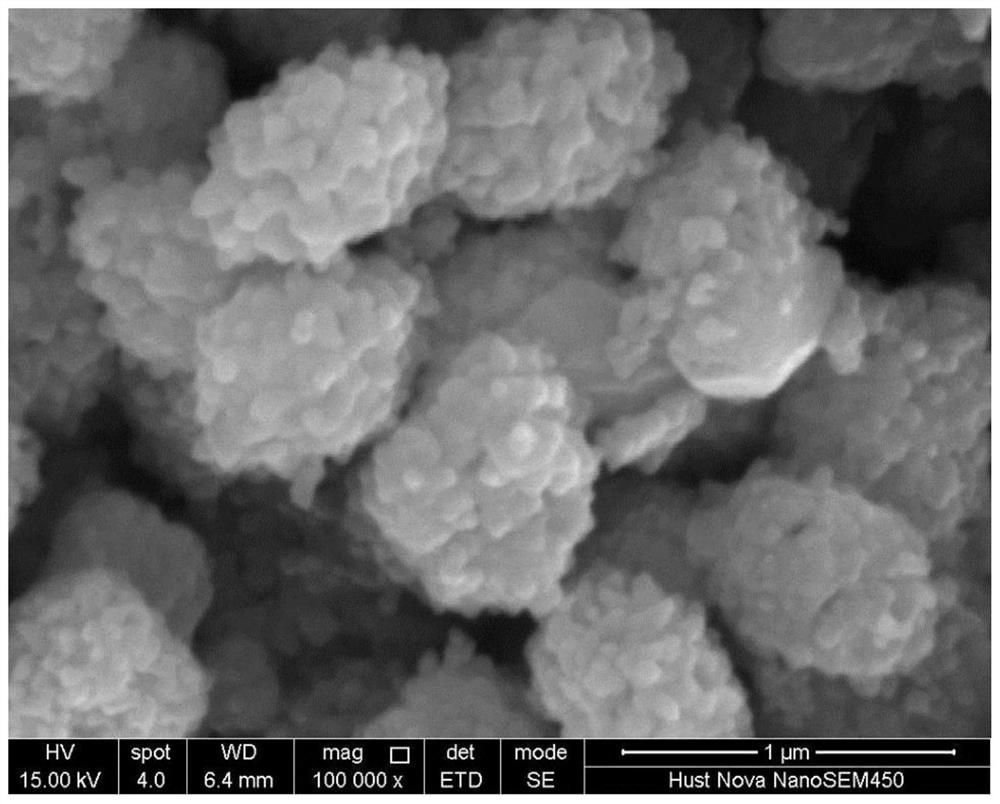

Embodiment 2

[0061] A lithium ion battery silver, cobalt and nickel doped lithium manganate positive electrode material, the specific steps of its preparation are:

[0062] A. 0.375 moles of manganese nitrate, 0.375 moles of manganese acetate, 0.1 moles of nickel sulfate, 0.1 moles of nickel acetate, 0.025 moles of cobalt nitrate, 0.025 moles of cobalt acetate, 0.135 moles of Li 2 O, 0.27 moles of lithium acetate, 0.01 moles of silver nitrate and 0.95 moles of sodium peroxodisulfate are mixed, fully ground or ball-milled into a reaction mixture, and the mixture is transferred to the stainless steel reactor lined with polytetrafluoroethylene;

[0063] B, stirring, to 18g of surfactant SDS, successively add 220mL of deionized water, 80mL of surfactant auxiliary n-butanol, 130mL of n-heptane to make the microemulsion transparent or translucent;

[0064] C. The microemulsion of step B is added to the reaction kettle of step A, mixed evenly, sealed, placed in an oven at 105 ° C for 32 hours of re...

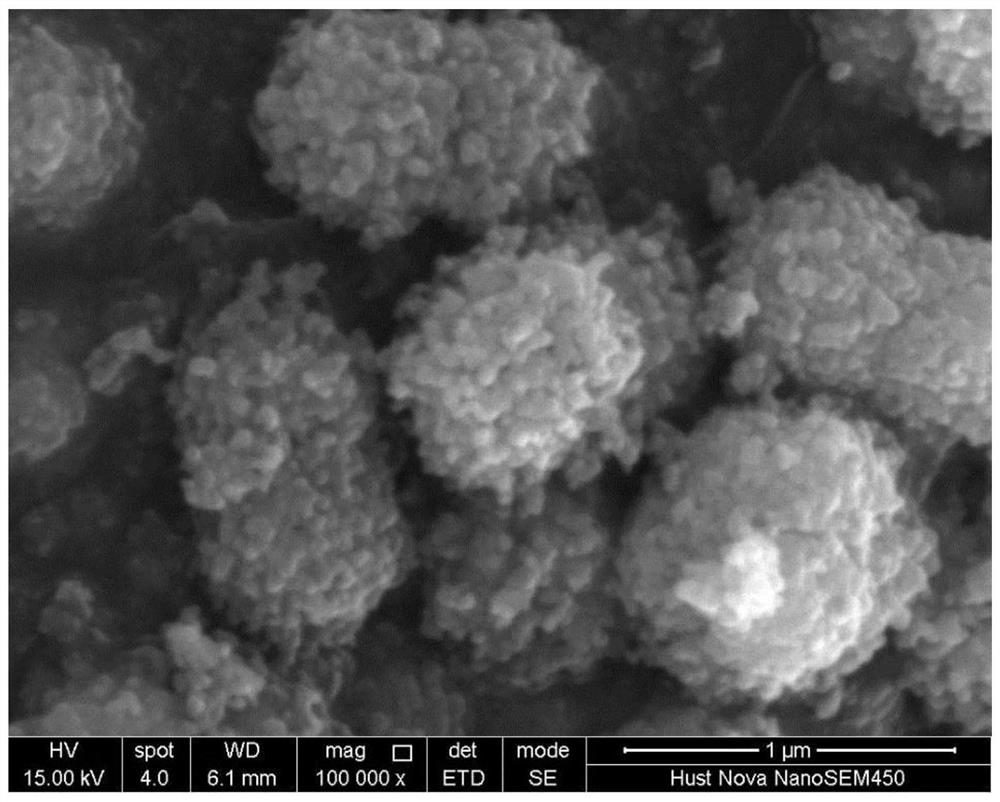

Embodiment 3

[0068] A lithium ion battery silver, cobalt and nickel doped lithium manganate positive electrode material, the specific steps of its preparation are:

[0069] A. Mix 0.3 moles of manganese sulfate, 0.3 moles of manganese acetate, 0.325 moles of nickel nitrate, 0.075 moles of cobalt acetate, 0.305 moles of lithium sulfate, 0.305 moles of lithium nitrate, 0.03 moles of silver nitrate and 1.0 moles of ammonium peroxodisulfate to form a reaction mixture, transfer the mixture to a stainless steel reaction kettle lined with teflon;

[0070] B. Stir, mix 16g of surfactant ABS with 200mL of distilled water, 60mL of surfactant auxiliary amyl alcohol, and 120mL of octane in turn to make a transparent or translucent microemulsion;

[0071] C. The microemulsion of step B is added to the reaction kettle of step A, mixed evenly, sealed, placed in an oven at 115° C. to react for 28 hours, and cooled;

[0072] D. Take out the mixture after the reaction in step C, filter, and rinse the filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com