Preparation method of cuins2 thin film solar cell absorber layer

A technology of solar cells and absorbing layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to prepare large-area thin films, high cost, low utilization rate of raw materials, etc., and achieve high utilization rate of raw materials, simple equipment, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

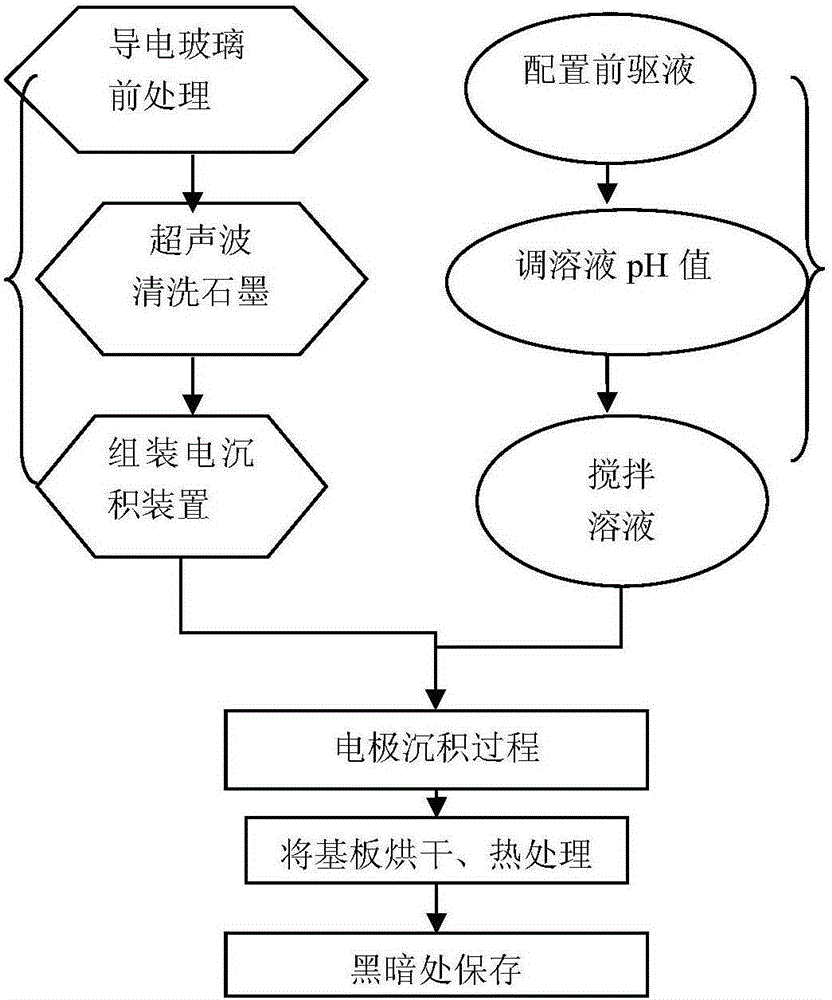

[0031] Specific implementation mode 1: CuInS in this embodiment mode 2 The preparation method of thin-film solar cell absorption layer is carried out according to the following steps:

[0032] 1. The substrate is ultrasonically cleaned with 50% hydrochloric acid, acetone, and absolute ethanol in sequence for 20 to 40 minutes, and then cleaned with distilled water for later use;

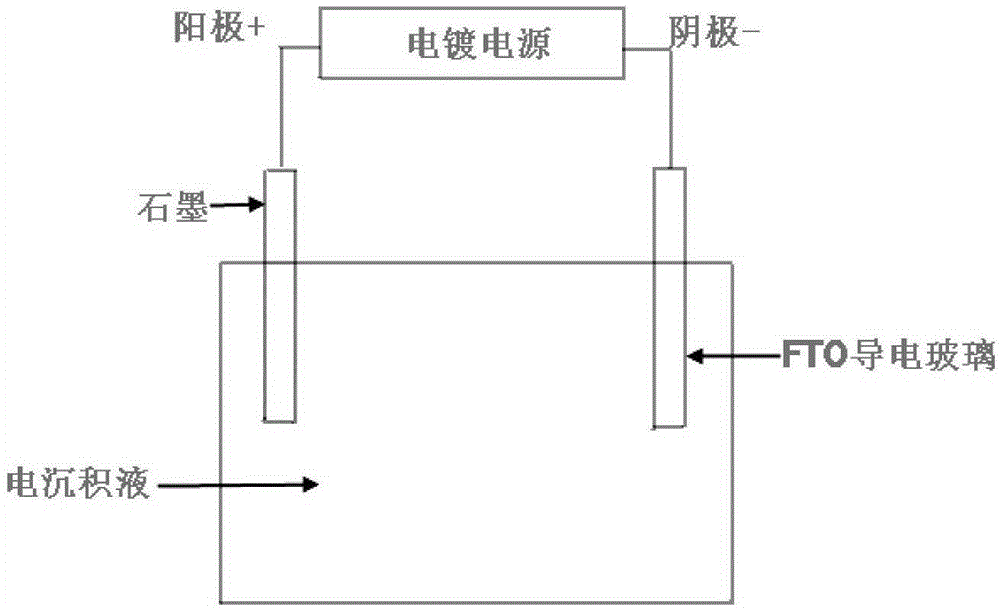

[0033] 2. Electrodeposition of CuInS 2 Film: Take 8~12mmol·L -1 CuSO 4 , 7~8mmol·L -1 In 2 (SO 4 ) 3 , 55~65mmol·L -1 Na 2 S 2 o 3 and 8~9mmol·L -1 C 6 h 5 o 7 Na 3 Prepare an electrolyte solution, and adjust the pH value of the electrolyte solution to 4, then place the substrate cleaned in step 1 in a bipolar electrolytic cell filled with electrolyte solution, perform electrodeposition treatment for 30-60 minutes, take out the substrate, and wash it with distilled water , blow dry;

[0034] 3. Place the electrodeposited substrate in step 2 in a tubular resistance furnace filled with ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the ultrasonic cleaning time described in Step 1 is 30 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: get 10mmol L described in step two -1 CuSO 4 , 7.5mmol·L -1 In 2 (SO 4 ) 3 , 60mmol·L -1 Na 2 S 2 o 3 and 8.5mmol·L -1 C 6 h 5 o 7 Na 3 Prepared as an electrolyte. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com